The initial situation

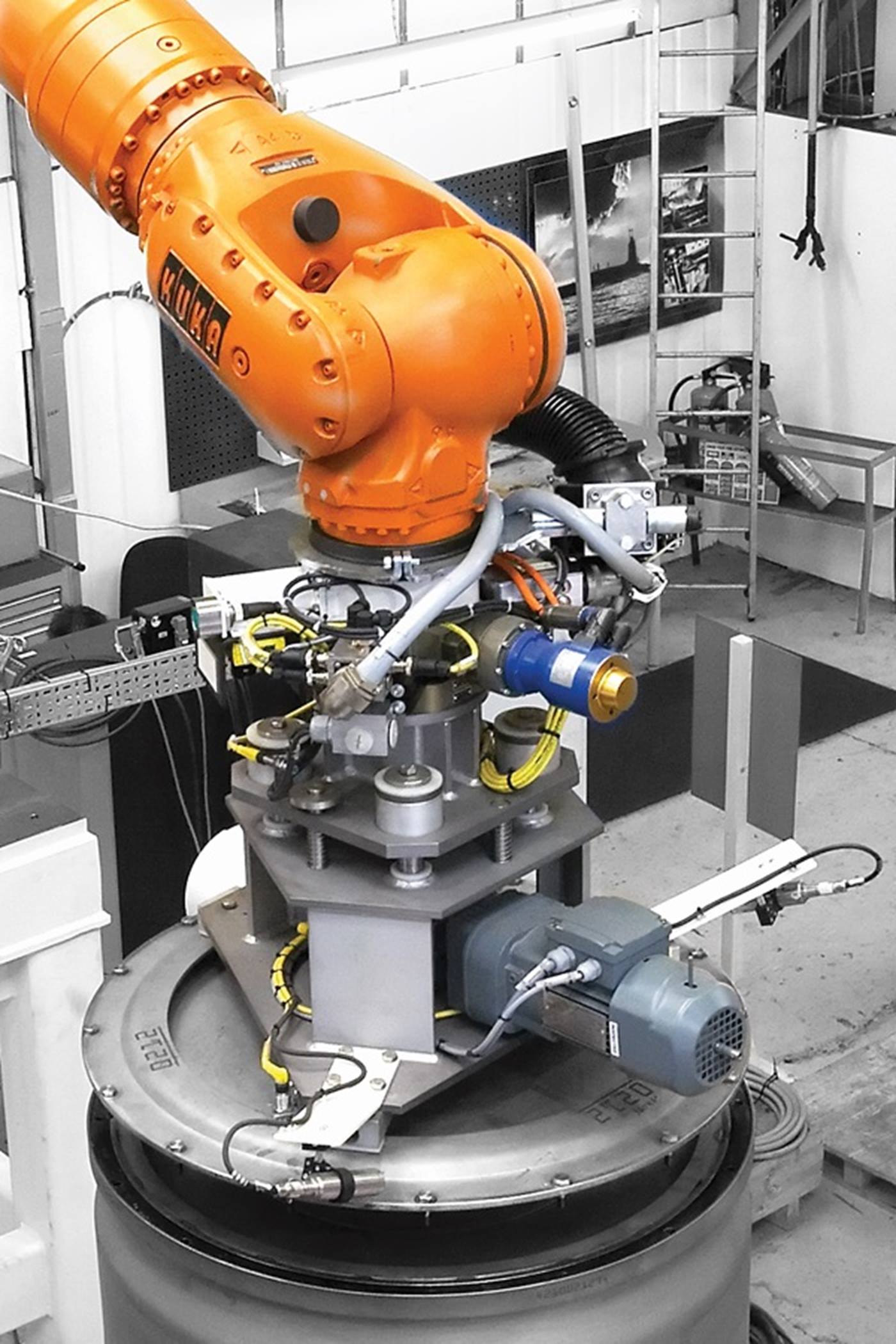

A nuclear facility is currently undertaking a huge clean-up operation which includes decontamination and decommissioning. As part of the clean-up of a key legacy facility on the site, a new plant is due to be commissioned in 2018. When complete, the plant will treat nuclear waste recovered from the storage silo programme, immobilise it and prepare it for long term storage. With the dangers involved for workers from exposure to harmful radiation, the contaminated nuclear waste is handled by robots, either automated or remotely by an operator. In order to evaluate their suitability for the new plant, a test rig with KUKA robots was set up. The goal was to determine whether they would be able to pick up, move and place simulated nuclear waste in a test environment.