Sealing and damping with KUKA – Fully automated system at Audi

In the automotive industry, it is becoming increasingly important to produce sustainably and efficiently. As an alternative joining method, adhesive and sealing technology in body-in-white production makes it possible to reliably join a wide variety of materials. KUKA has extensive expertise in this field and is supplying a fully automated production system for Audi.

30 July 2020

In the second quarter of 2020, KUKA was awarded the contract for the planning, delivery, assembly and commissioning of ten robot stations for automated seam sealing and insulation application, including material supply. Several Audi models will be sealed and damped in a wide range of variants on this production line.

Sealing and damping – seam by seam

In future, 42 KUKA industrial robots in ten fully automated stations at Audi's main plant in Ingolstadt will provide corrosion protection, leak-tightness and acoustic damping. The goal is to assemble a completely new, fully automated production system, including material supply.

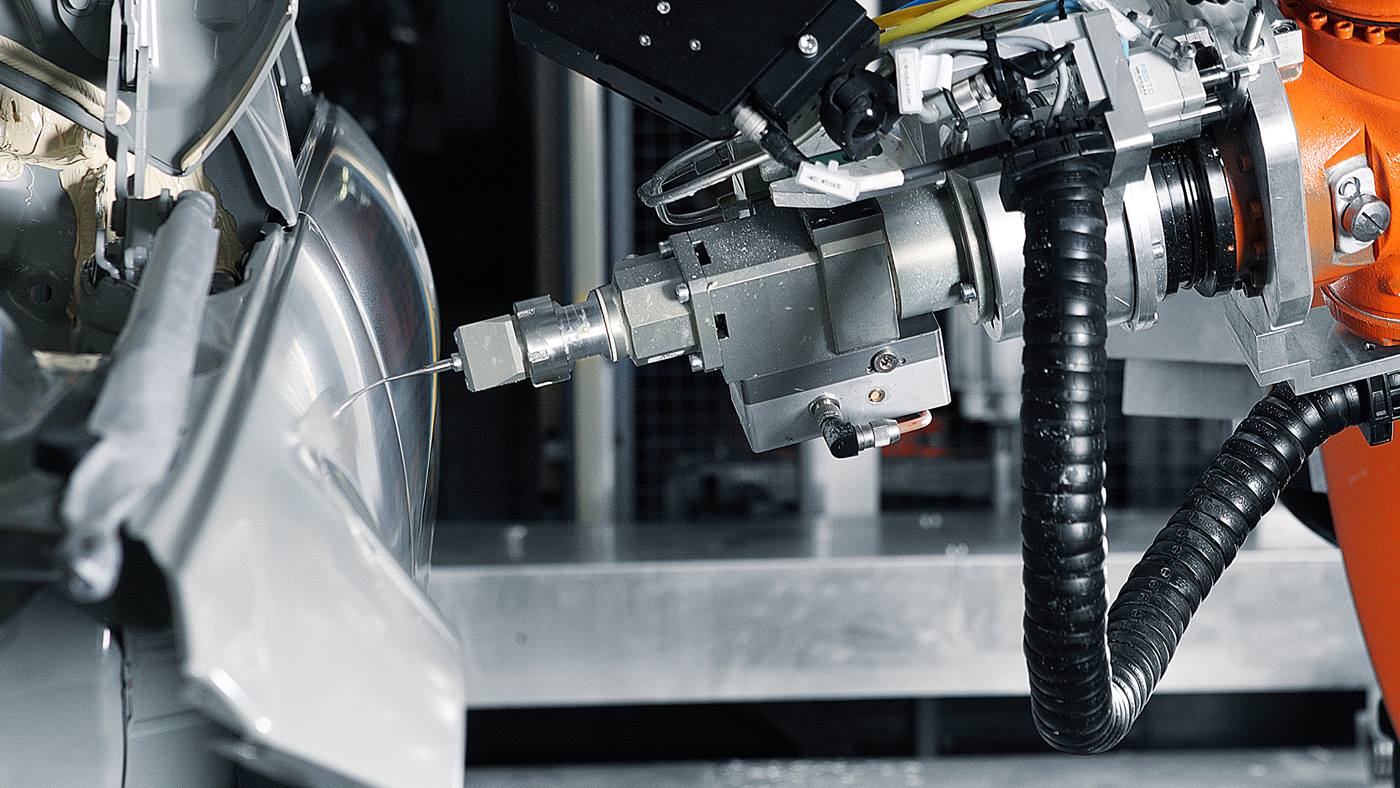

Seam sealing and application of sprayable damping material are two closely related processes in the painting field. In this process, the car bodies on the underbody and in the interior as well as the body parts at the sheet metal transitions are sealed with PVC. The sprayable material is applied to the interior of the body for acoustic damping. The robots mounted on KUKA linear axes, equipped with application technology, perform this task.

The new production system is characterized by high flexibility and quality. KUKA is applying its extensive and long-standing technological expertise here.