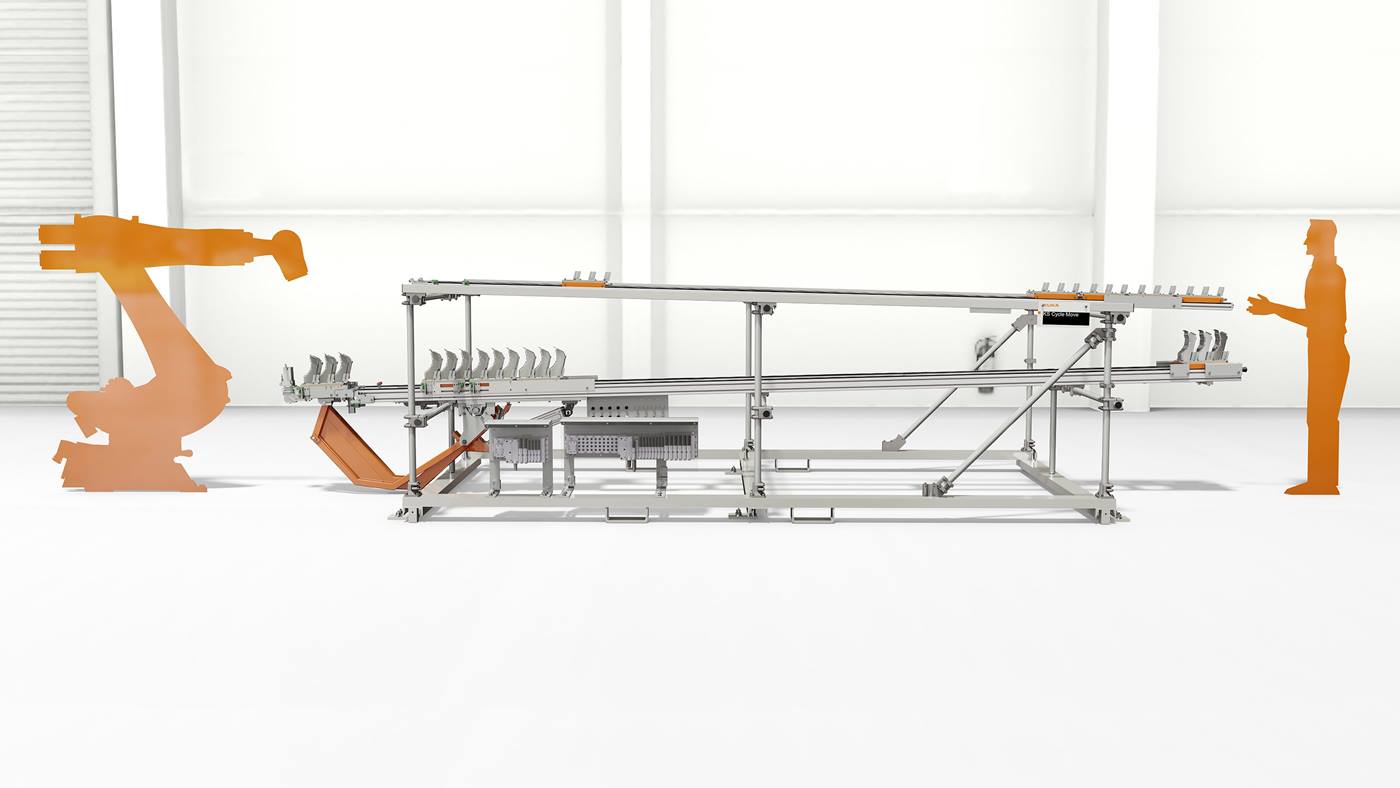

The KS Lift-and-Carry Shuttle is characterized by its high traversing velocity combined with its compact design. The simple structure comprising standardized components ensures that you can use the shuttle within your line with minimum obstructions.

All over the world, about 150 KS Lift-and-Carry Shuttles are being used in production at all kinds of automotive companies. Our customers include BMW, Daimler, Ford, Opel and Volkswagen.

How the KS Lift-and-Carry Shuttle functions

The entire process of the KS Lift-and-Carry Shuttle consists essentially of four steps:

1. Picking up the components by a lifting movement

2. Horizontal transport to the next station

3. Lowering the components to the new workstation

4. Empty travel back to the starting position

In reality, these four steps take place very quickly: The lifting and lowering times are about two seconds each, and the straightforward traversing time is between three and six seconds.

Advantages of the KS Lift-and-Carry Shuttle

- Modular structure: The KS Lift-and-Carry Shuttle can be supplied in variants with between four and ten stations, according to requirements.

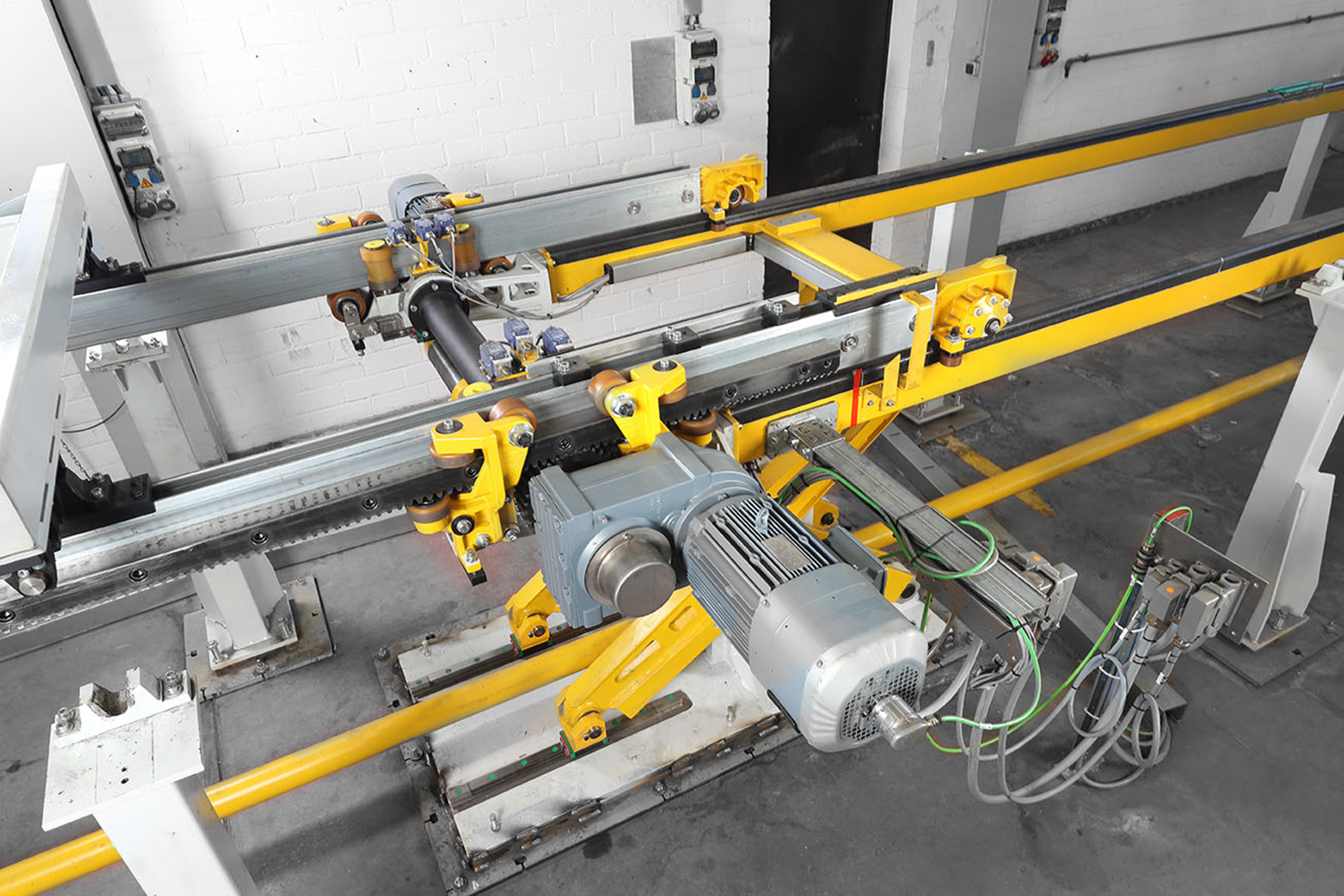

- Cost-effective: Only one motor is required for lifting and lowering, so the shuttle only generates very low operating costs.

- Efficient ranges of motion: The motion profiles can be individually optimized.

- Variable station spacing: The station spacing is adjusted to the customer's requirement.

- Fast: Optimized transport times thanks to modular horizontal drive with one or two motors.