Friction Stir Welding: Battery manufacturers should invest in technology and expertise now!

For non-ferrous metals with lowmelting points and other metallic materials, friction stir welding (FSW) offersdistinct advantages over conventional welding techniques. Robotic FSW enhancesthe quality of battery housing production, setting new benchmarks in precisionand reliability. These modular and scalable robotic FSW solutions can bedeployed and customised swiftly, with minimal capital expenditure.In this context, FSW specialists Mr. Till Maier and Mr. Stefan Fröhlke fromKUKA share insights on the importance of international collaborations insuccessfully implementing FSW technologies.

When you purchase a friction stir welding cell from KUKA, you are not just buying a device – you are buying a ready-to-use solution!

What other advantages does robot-based FSW offer?

Friction stir welding is a green technology!

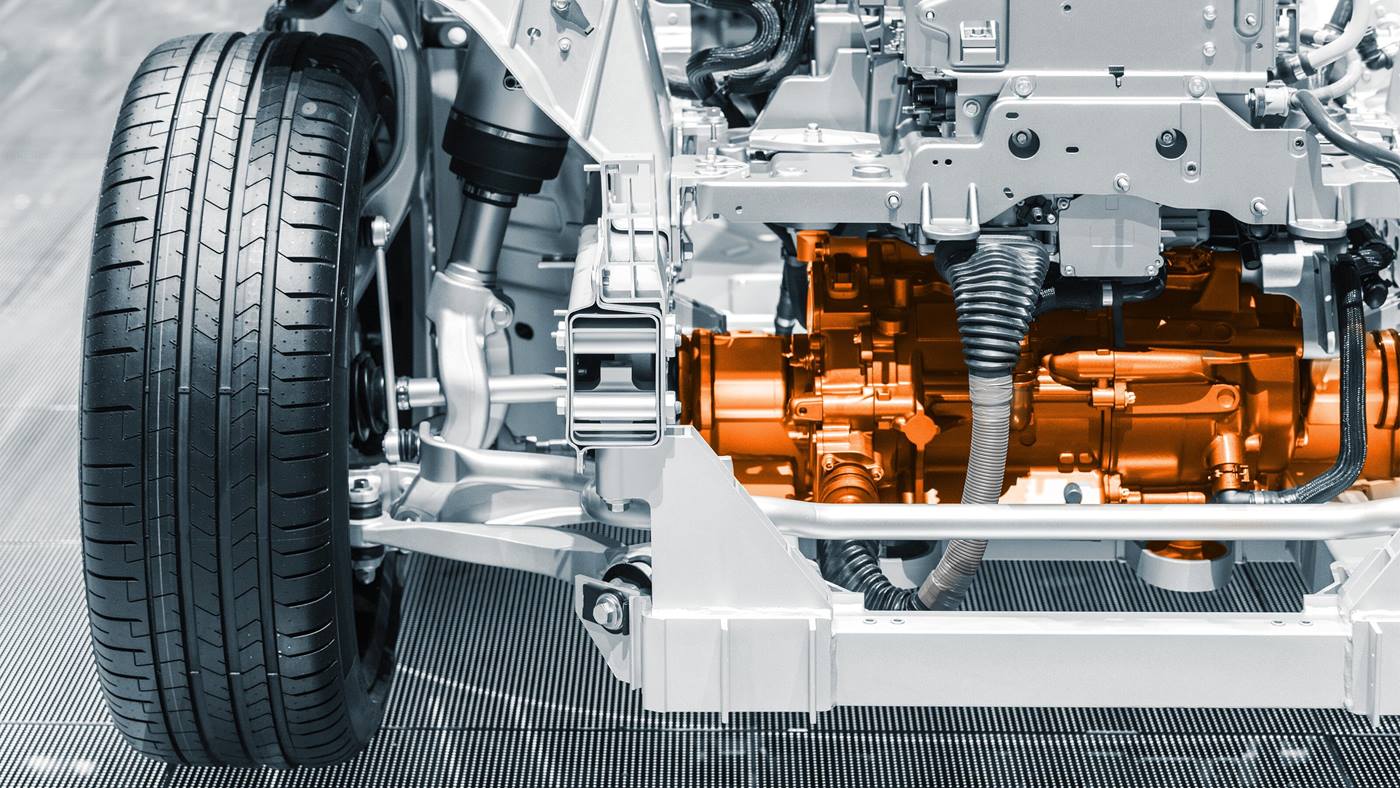

FSW is becoming increasingly popular with battery manufacturers in the automotive industry. Why is that?

With more than 270 FSW robots in over 18 countries since 2012, KUKA has become one of the world market leaders in robot-based FSW. Which sectors are the interested parties coming from?

Have there been any research collaborations of this kind with partners in India?

What does the abbreviation “PCD” stand for?

All of this shows that KUKA offers its partners much more than just robots and the associated FSW technology.

How does such a project actually work in practice?

What do the employee training courses you mentioned look like?

However, you not only offer customer-specific training courses, but also individualized solutions for FSW tailored to the specific requirements of each customer: How does that work?

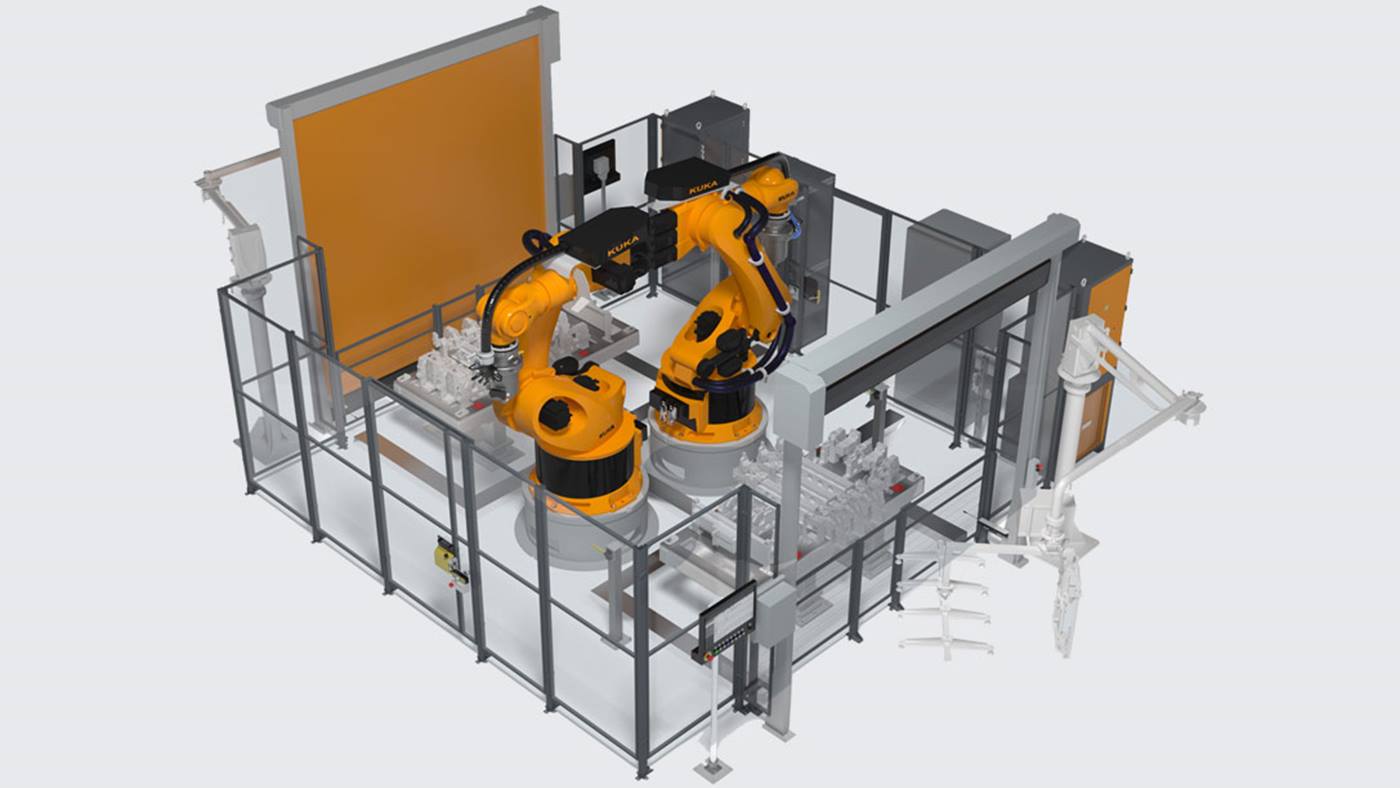

Mr. Till Maier: We basically have three solutions in our robot portfolio: First, the new KR FORTEC ultra in the MT version with a payload of 300 kilograms and a reach of up to 2,800 millimeters (KR 300 R2800-2 MT). We offer this robot as a universal, robot-based 3D application module for complex 2D and 3D FSW applications. Then there is the modular robot cell KUKA cell4 FSW midsize single in combination with the above mentioned robot for medium sized applications with maximum process utilization, such as HEV battery housings. And finally, the robot cell KUKA cell4 FSW large dual, also with the above mentioned robot, for large applications with maximum process utilization, such as BEV battery boxes. Our FSW robot cells have been specially developed for the growing e-mobility market. They have a modular design and are therefore scalable for different production volumes, making them very versatile with a wide range of configuration options.

Mr. Stefan Fröhlke: Our KR FORTEC ultra MT is not a conventional pick-and-place machine, but a special MT (machine tooling) variant. Axes 1 to 3 have been optimized with special gear stages and motors, enabling enormous process forces of up to 12 kilonewtons and in some cases even more. Thanks to the new double swing arm and new machine data, the KR FORTEC ultra MT is extremely rigid and has been specially developed for the FSW process. This ability to apply high forces with precise repeatability sets us apart from other robot manufacturers – KUKA was one of the absolute pioneers in this field. But the individual tools on the robot and the clamping devices are also customized.

What tools are these, for example?

Customers often argue that robot-based FSW does not meet their requirements because the robots are not rigid enough, and they invest a lot of money in large gantry systems. What do you say to them?

Mr. Stefan Fröhlke: Quite clearly: our new KR FORTEC ultra MT and our already widely used KR 500 MT are sufficiently rigid and highly precise, and thanks to their more powerful motors, they have the necessary power to perform FSW precisely for most e-mobility applications. We have also developed a kind of path calibration system for it. This allows us to measure its position throughout the welding process using a laser tracker, respond online in real time, and keep the robot on course. Thanks to a path accuracy of less than 0.5 millimeters, high precision weld seams are possible. In short, this robot system is very well suited to the high forces involved in FSW.

Mr. Till Maier: With the new KR FORTEC ultra MT, we have gone one step further, as it can apply up to 20 percent more process forces. The new models, available since spring 2025, also have a reach of up to 3,400 mm, which increases the effective working range for KUKA customers in FSW. But the KR FORTEC was already extremely popular before that: no other robot has been sold as frequently for FSW applications in recent years!

Do you have any examples of practical applications?

Mr. Till Maier: We have currently received a follow up order for 12 FSW cells from a major US automotive manufacturer who had previously ordered 23 cells from us. The cells are used in several production steps: The robots weld battery carriers together and, in a second production stage, connect cooling plates to the battery carriers. However, KUKA not only supplies the technology, but is also responsible for the entire friction stir welding process – including assembly, commissioning, training, and final acceptance. What is particularly exciting here is that the comprehensively converted production facility can be used to build vehicles with combustion engines, hybrid vehicles, and electric vehicles on the same production lines.

Mr. Stefan Fröhlke: This is remarkable because hybrid electric vehicles and exclusively battery-powered vehicles place very different demands on production. In hybrid vehicles, we have smaller battery housings made of cast aluminium. These have cooling channels, and our task is to close these cooling channels. In purely battery-powered vehicles, on the other hand, the battery housings are much larger and weigh much more. This means that many components are made of different aluminium alloys.

Mr. Till Maier: Eight of our robots, including three FSW application modules with the KR 500 MT FORTEC in three KUKA cell4_FSW cells, have also been in operation at a major automotive supplier in Portugal since 2022. The supplier was dissatisfied with the welding quality of another manufacturer's system. We initially developed a system with two cells, each with a KR 500 MT FORTEC, for them. The customer was so impressed with the flexibility of being able to weld different battery boxes on one system that they immediately ordered another system — a cell with a robot that can operate three fixtures. This allows three different welding tasks to be performed, which would otherwise require three non-robot-based systems. The FSW robot can be utilized at up to 95 percent capacity, as the fixtures can be loaded and unloaded in a separate safety area during the welding process.

You have now given many good reasons why those interested in FSW should contact KUKA. What is the most important one?

Mr. Till Maier: We offer manufacturers who want to grow affordable entrylevel solutions for robot-based FSW. Together with them, we develop agile production concepts that are modular and scalable and can therefore be flexibly expanded as demand increases. Customers benefit from our comprehensive expertise: Some companies supply a robot, others a spindle or special tools, but then lack the necessary process know-how. We can offer all these components, processes, and knowledge from a single source. Not only do we train the companies' employees with our decades of expertise, but we also remain at their side as a competent partner beyond the commissioning of the systems. We see cooperation as a genuine and sustainable partnership! In addition, we design and program our robots so that they are optimally tailored to the individual requirements of our customers – from conception to implementation, we have an influence on all relevant process steps.

Mr. Stefan Fröhlke: Through our extensive, direct cooperation with end customers, we also gain valuable experience that we continuously incorporate into our solutions. We see ourselves as a solution provider that, in addition to its own robot technology, has over 20 years of expertise in clamping technology, tool development, and process technology — crucial knowledge for industrial implementation! As integrators, we vouch for the quality of a system and solve even tricky tasks using a wide variety of methods. If desired, we can offer our customers complete, turnkey solutions that are perfectly tailored to their individual requirements. In other words, KUKA is the right partner for FSW in e-mobility, from the initial product idea to the complete finished solution.

Friction stir welding: Future technology on the rise