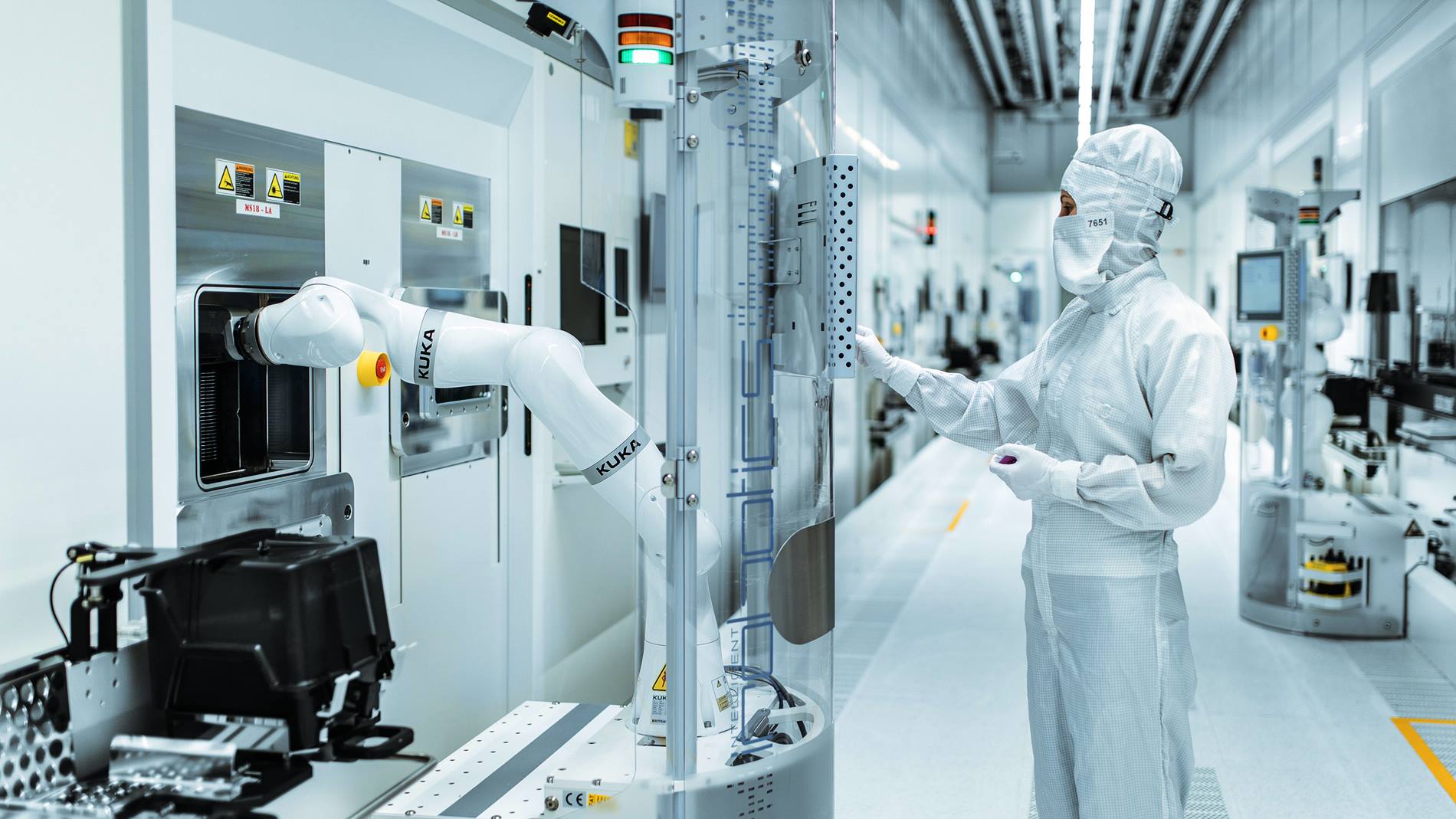

Designed for the stringent clean working requirements of the semiconductor industry: KUKA places particular emphasis on cleanrooms and facility safety.

Especially for cleanroom manufacturing, KUKA offers low-particle and low-emission robots, cobots, and platforms for the manufacture and safe handling of highly sensitive microelectronic devices, such as chips and semiconductors. Even our own production facility operates under this strict cleanroom environment.

Together with system partners, KUKA supplies future-proof Industrie 4.0 solutions for the semiconductor industry with perfectly matched hardware and software meeting the demands of networking capability and manufacturing flexibility.