PLC decides on the palletizing system

Incoming orders are entered into the SAP ERP system which schedules the orders, optimizes them for production and sends them to the KOCH PLC control system. The machine data collection runs on a new MES system, a specific industry solution for reel manufacturers and converters. The PLC compares the reel diameter and the corresponding palletizing pattern with the size of the intended load carrier and carries out a plausibility assessment to decide whether it’s possible to palletize automatically. Otherwise the rolls are sent to a separate packaging line.

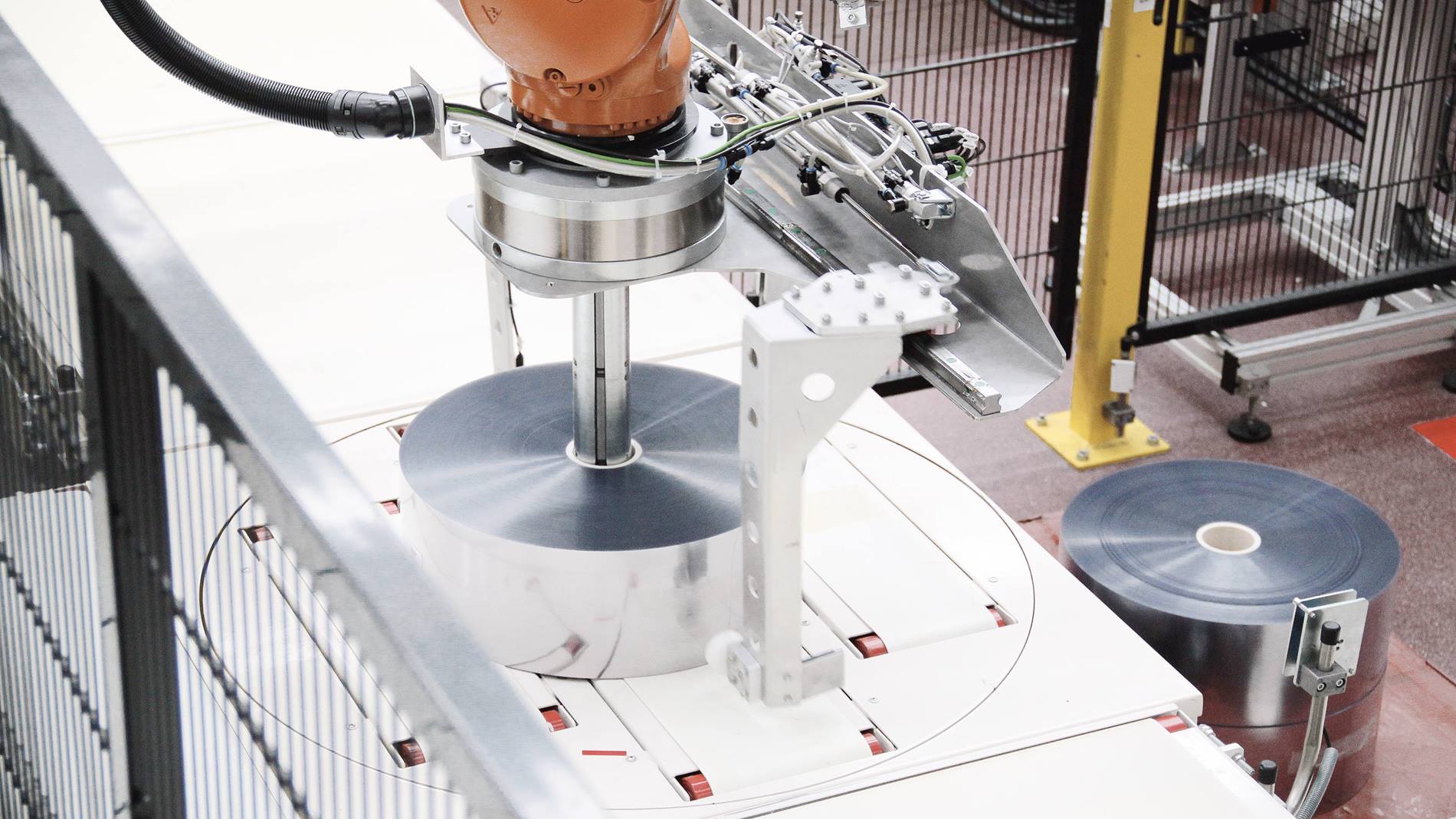

A fully automatic system has been developed to position the cores. In this case, a KUKA KR 6-2 takes on the central positioning and measuring function to ensure that the core is in the correct position. Depending on the order, the robot positions between two and 20 cores. It also removes the core automatically from a magazine or may also be connected directly to a core cutter. Then the robot places the core on a so-called clamping and transfer unit which ensures that the cores are properly pushed onto the winding shaft.

The great advantage here is that the cutting machine and the robot work independently of each other. When there is a new order, the robot receives the new cutting widths and positions from the order management system and the prescribed cutter adjustments.

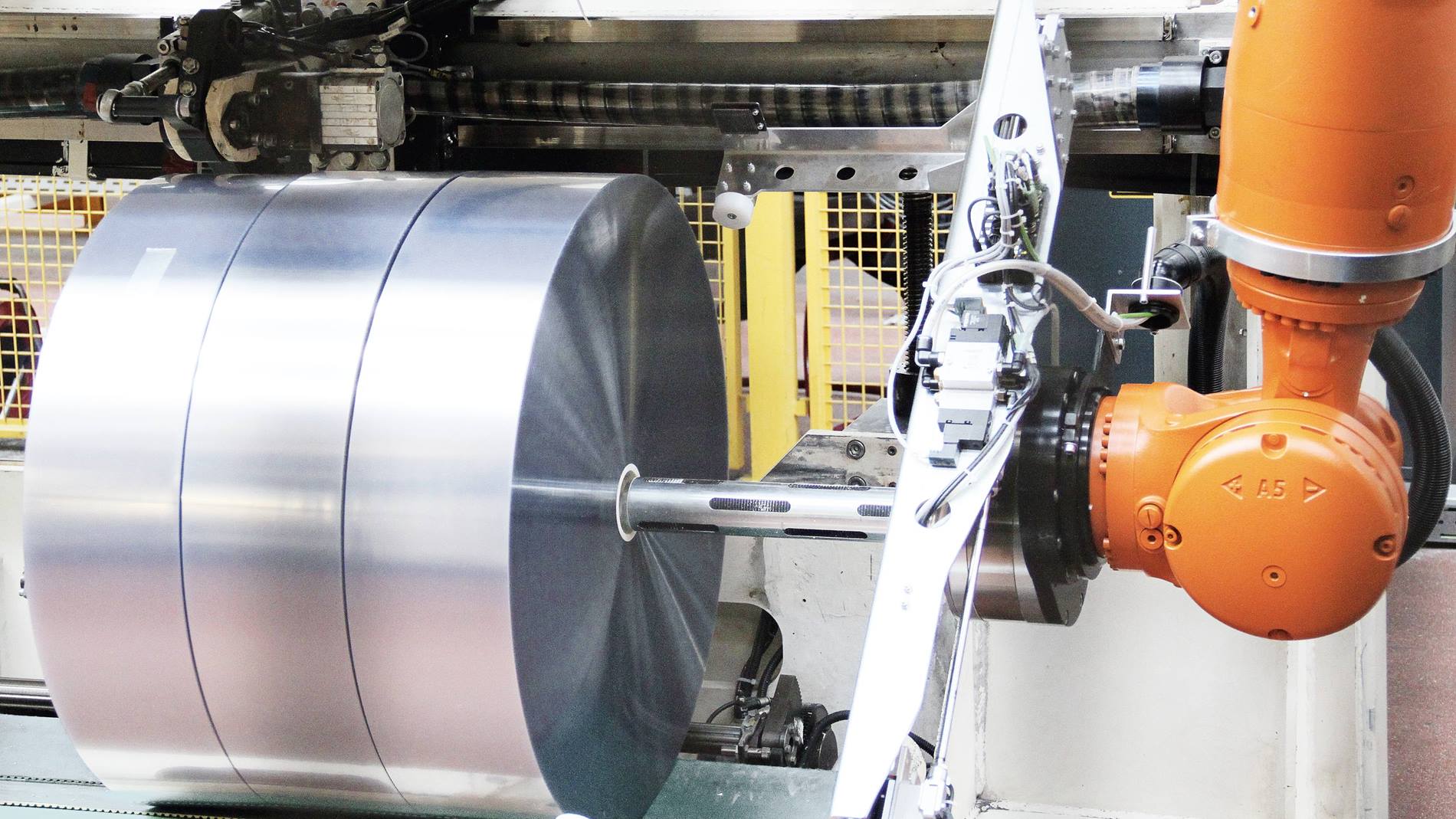

The KR QUANTEC robots of type KR 300 R2500 ultra assigned to the reel splitters remove the finished film reels, which have diameters of 250 to 800 millimeters, weights of ten to 200 kilograms and widths of 75 to 450 millimeters, and lay them on a conveyor belt. The robots in the system are equipped with clamping grippers which only exert slight pressure from the outside so that the film reels are not damaged.

The grippers are set in accordance with the reel diameters by the machine controller. The robots start and brake smoothly so they don’t damage the edges of the reels when setting them down. The KR QUANTEC robots not only have a high load capacity of 300 kg and a reach of up to 2500 mm, but also offer impressive flexibility – these experts can handle a variety of weights, diameters and widths with ease.