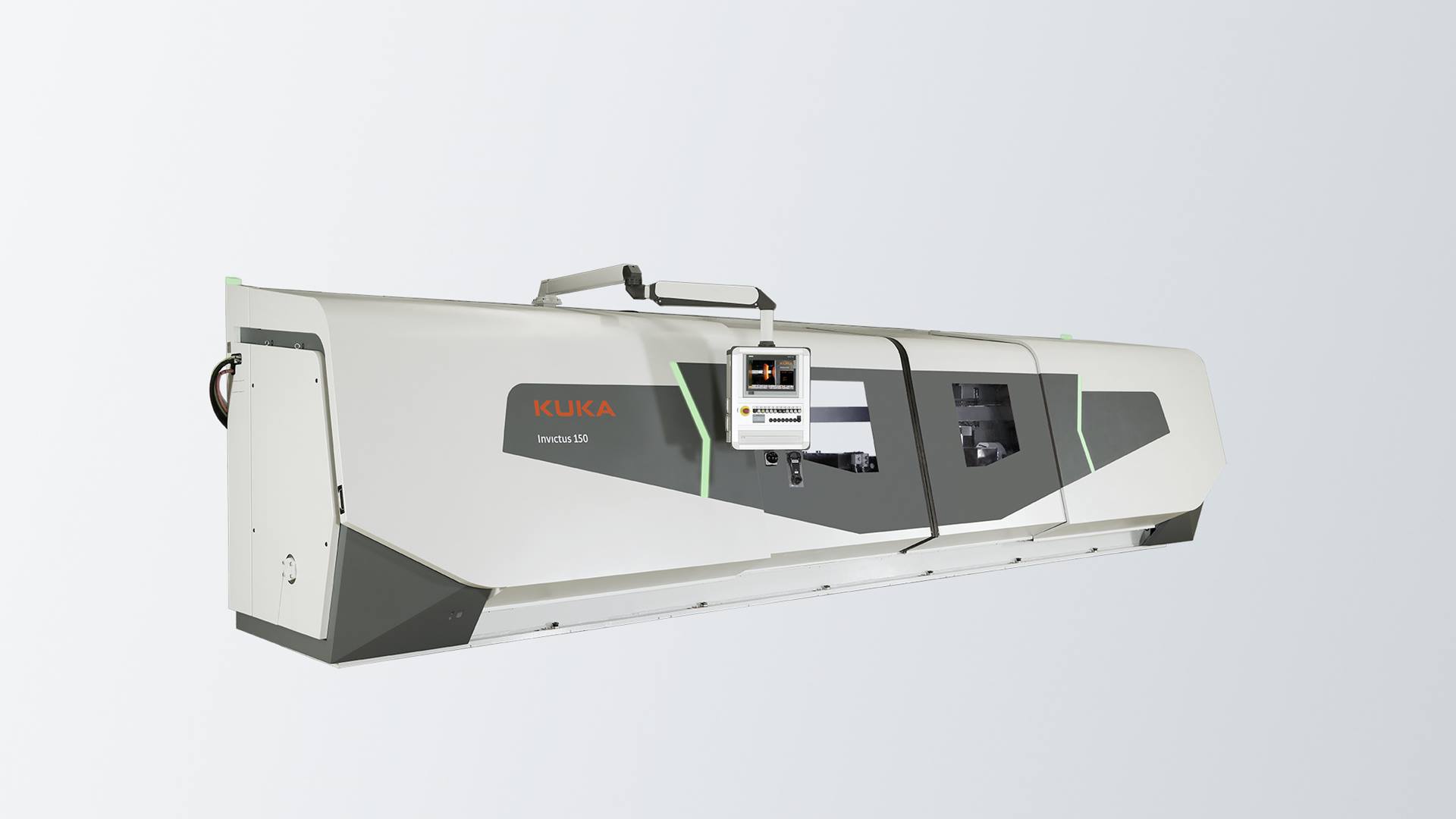

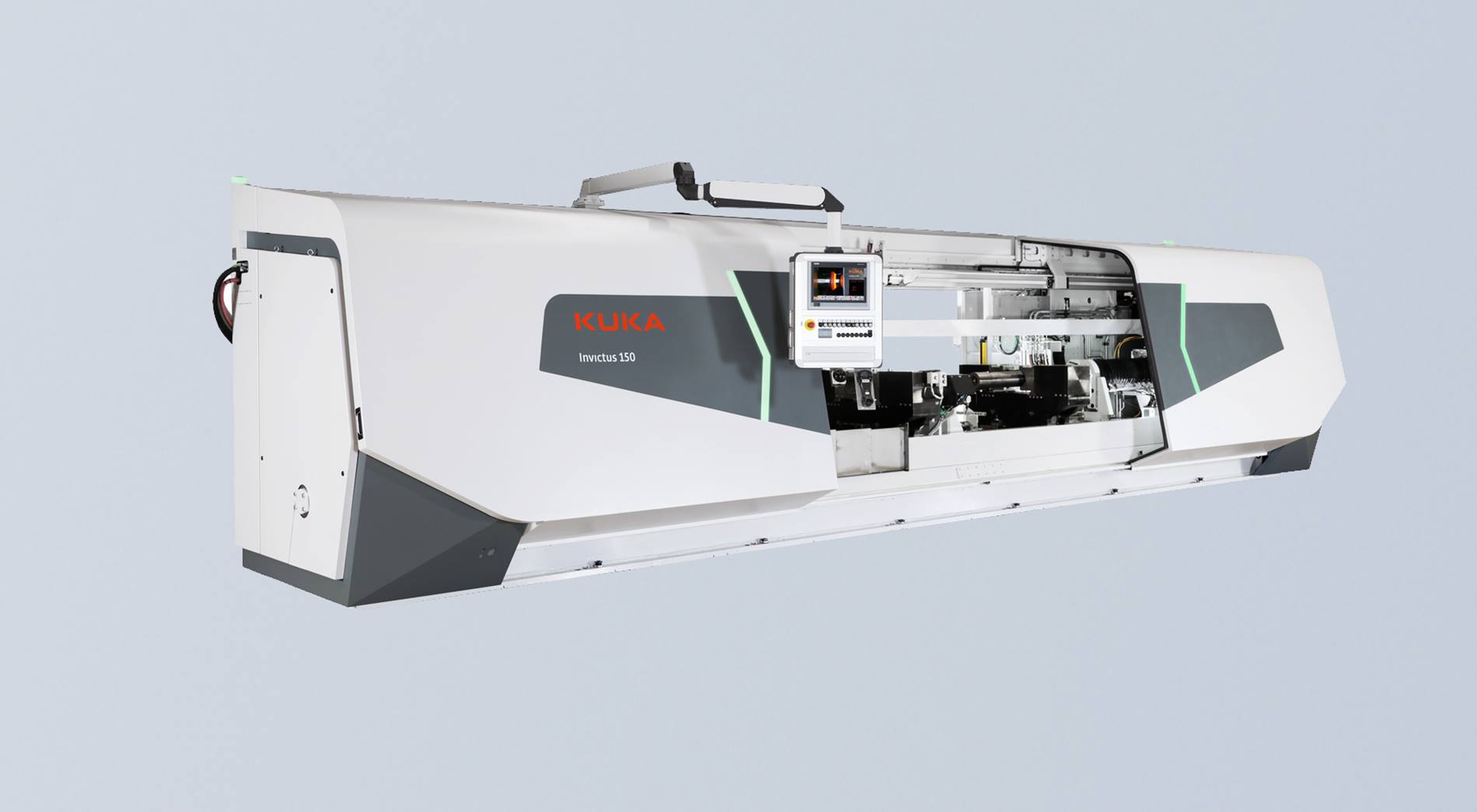

KUKA Invictus

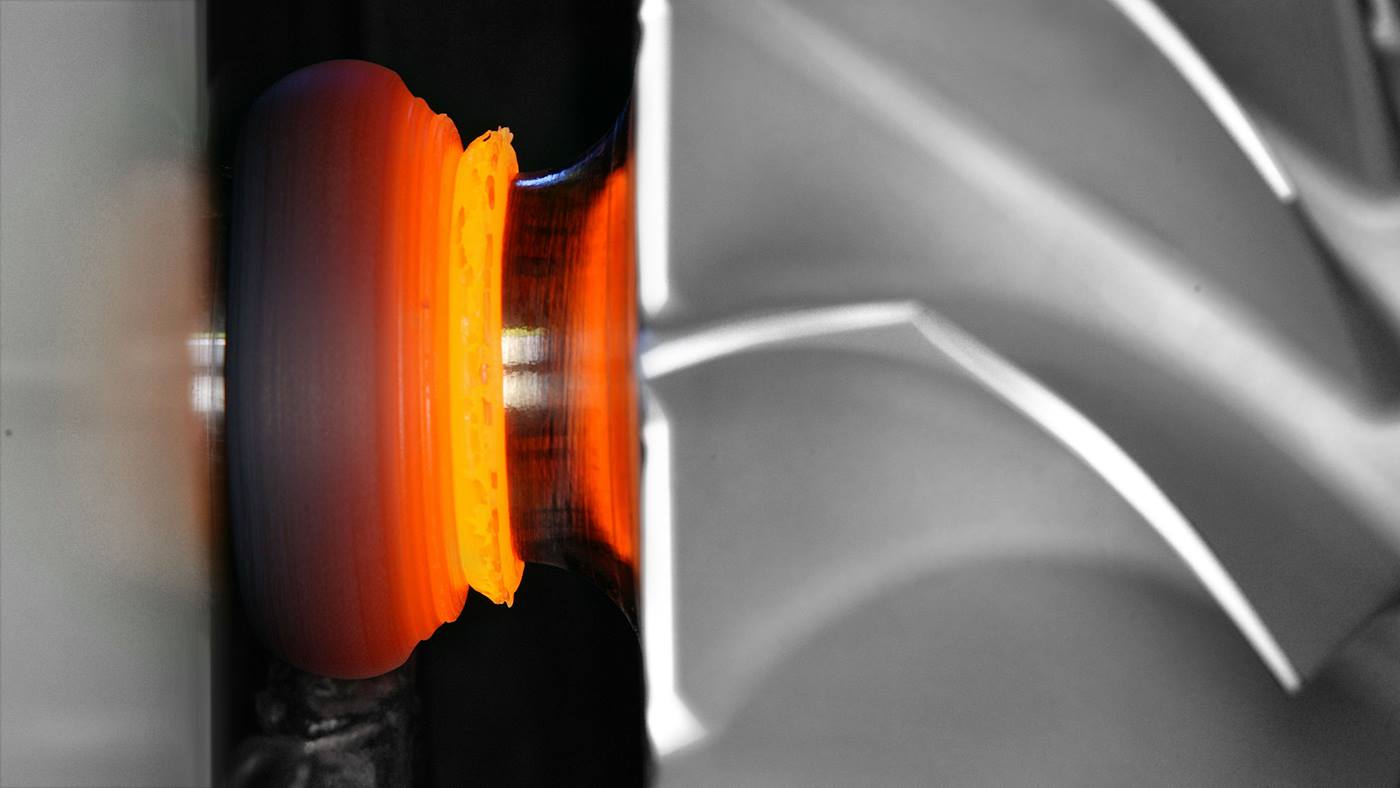

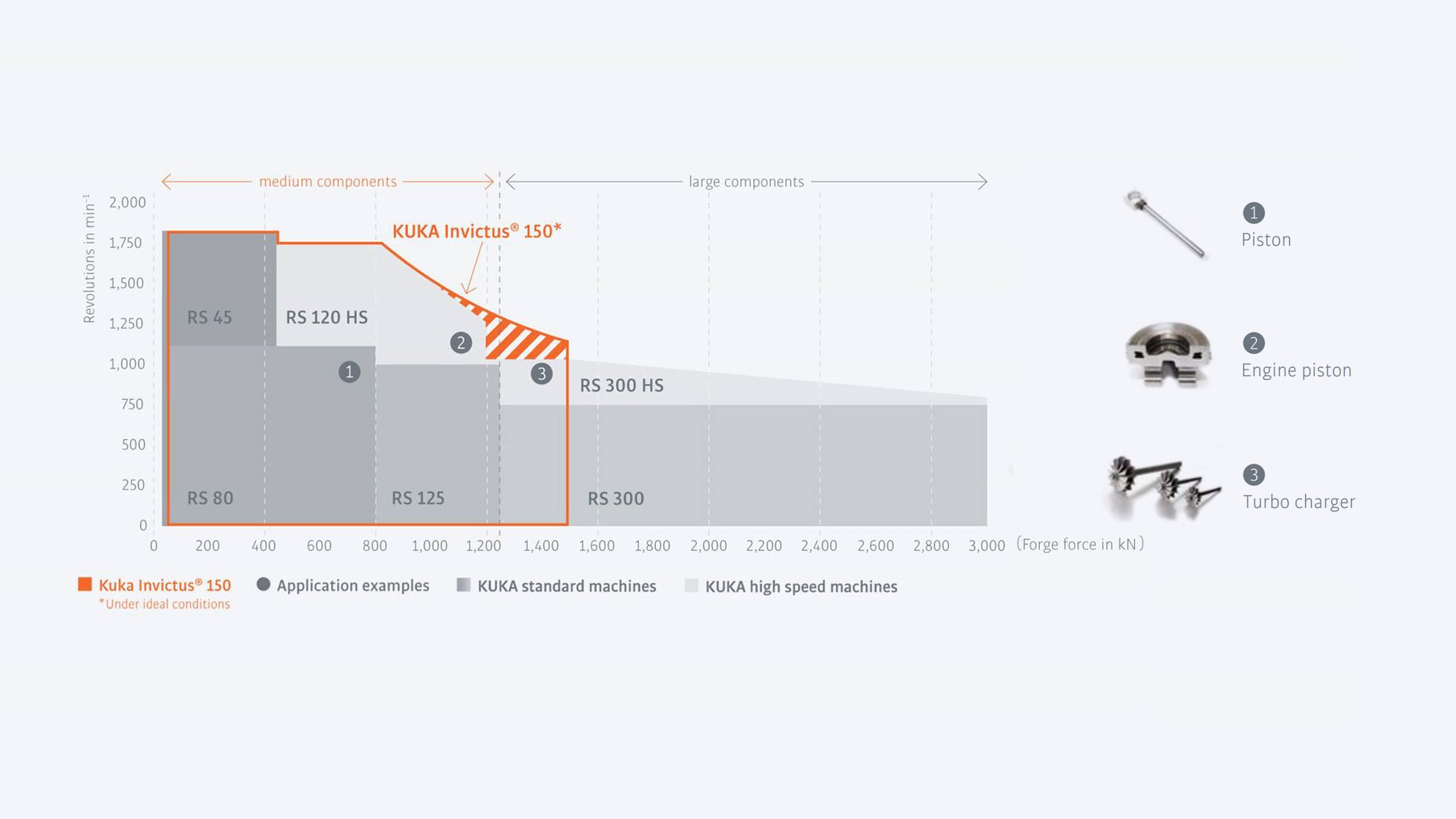

强大、快速和精确:适合中大型工件的摩擦焊接机凭借高达 1500 kN 的顶锻力及其广泛的用途而备受青睐。

KUKA Genius 详情

-

最方便的入口

![]() 易于接近 - 大尺寸的操作门和检修门可确保从上方和机器正面最佳地接近工作空间。

易于接近 - 大尺寸的操作门和检修门可确保从上方和机器正面最佳地接近工作空间。 -

方便易用的操作面板

![]() 触摸屏操作凭借清晰明了的菜单导航使 Genius 的操作直观而易学。具有查找功能和保养计划的数字操作手册进一步提升了用户友好度。

触摸屏操作凭借清晰明了的菜单导航使 Genius 的操作直观而易学。具有查找功能和保养计划的数字操作手册进一步提升了用户友好度。 -

适合运输的结构设计

![]() 即插即用 - 液压和电气系统的集成降低了空间要求并简化了运输和安装

即插即用 - 液压和电气系统的集成降低了空间要求并简化了运输和安装 -

工作空间

![]() 符合人体工学且易于接近的工作空间,可轻松上料和装配。易于清洁的内饰板可防止电缆和管道脏污和损坏。

符合人体工学且易于接近的工作空间,可轻松上料和装配。易于清洁的内饰板可防止电缆和管道脏污和损坏。 -

集成的光幕

![]() 确保最高安全性的同时缩短节拍时间 - 集成的光幕在保证最高安全等级的同时优化了节拍时间

确保最高安全性的同时缩短节拍时间 - 集成的光幕在保证最高安全等级的同时优化了节拍时间 -

灵活的碎屑输送机

![]() 凭借优化的结构设计,排屑装置首次可以选择安装在机器侧面或背面。

凭借优化的结构设计,排屑装置首次可以选择安装在机器侧面或背面。

可以根据客户的要求与客户一起对 KUKA Genius 的大量技术模块进行配置 – 这正是未来用户的部件、生产计划和生产策略所需要的。