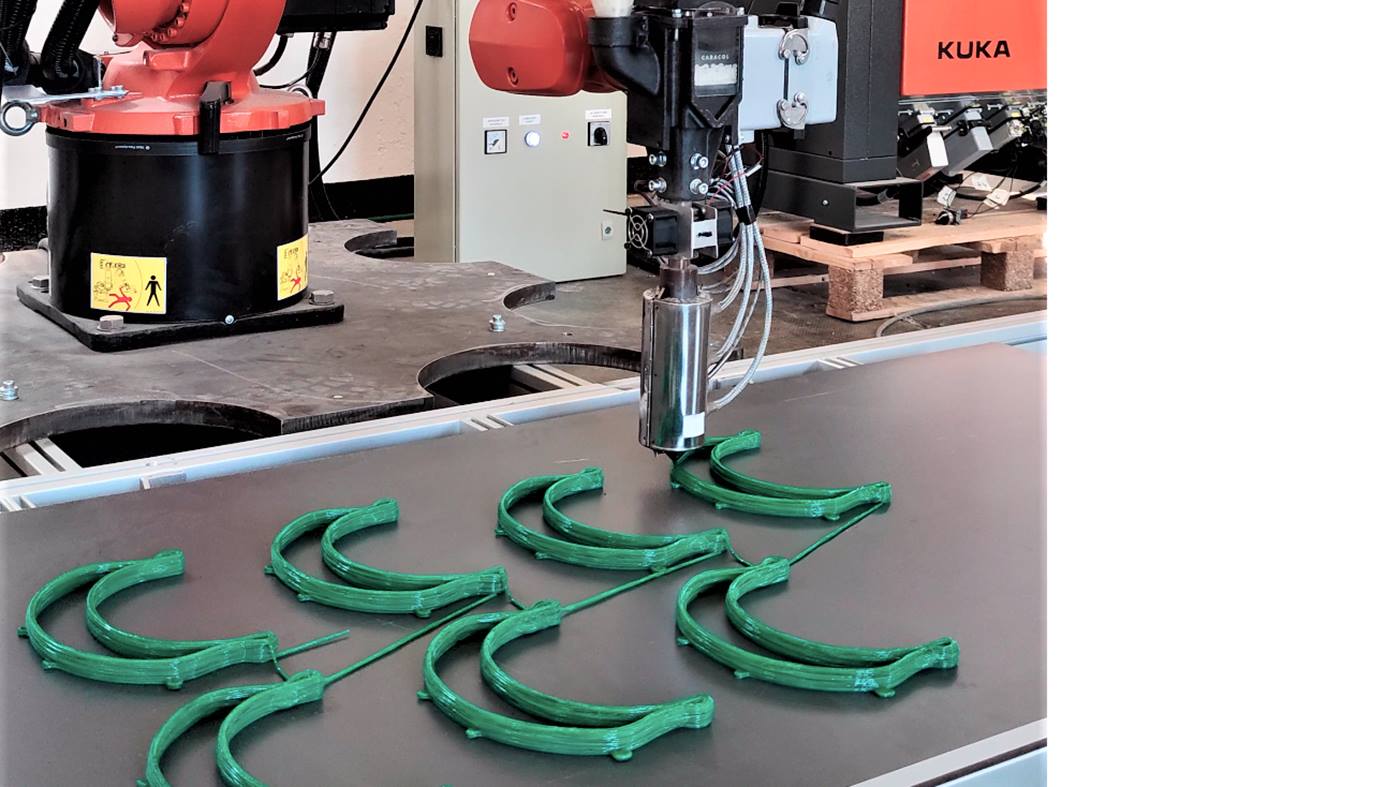

With 3D Printing Against Corona: KUKA Robots Print Protective Equipment in Northern Italy

Every five minutes, KUKA robots in northern Italy print head brackets for face shields. More than 1000 are thus produced every day. The Italian company Caracol-AM is donating parts of the production to local hospitals and institutions.

May 12, 2020

Since the beginning of the corona pandemic, the demand for face shields has risen rapidly. Caracol-AM has used its experience in the field of additive manufacturing to develop an automated 3D printing solution with KUKA robots. Head mounts for face shields are printed. Additionally, industrial 3D-printers print reusable protective masks.

"During the Covid 19 emergency, we want to make a contribution with our 3D printing processes. Thanks to our experience in this field, we were able to react quickly and convert our production," says Francesco De Stefano, CEO of Caracol-AM. "Our robotic systems and industrial printers are running at full speed to produce protective equipment. The headgear printed by the KUKA robots is complemented by a plexiglas, which Caracol-AM purchases from a partner company, to protect against droplet infection.

Caracol-AM has been active in the field of additive manufacturing for three years and employs 15 people. "Our KUKA robots help us to produce quickly and meet the high demand for protective equipment. The robot systems are in operation around the clock", explains De Stefano.