The Power of Automation

Sunstall teams up with Cosmic Robotics to deploy robotic automation that eases labor strain and expands the available workforce for large-scale solar projects.

Sunstall: Building the Physical Infrastructure of Solar Power

The Physical Demands of Solar Module Installation

Labor Constraints and the Push Toward Automation

Partnering with Cosmic Robotics

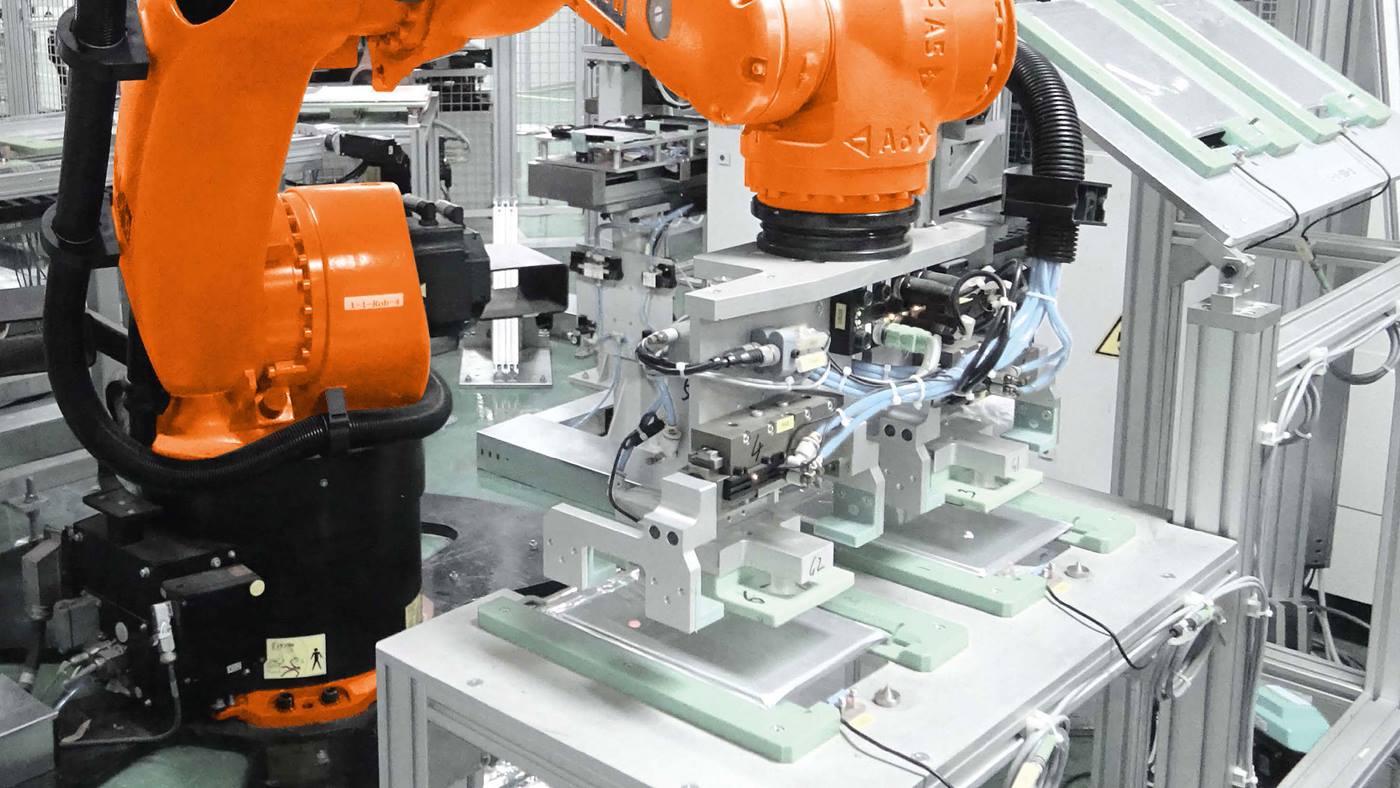

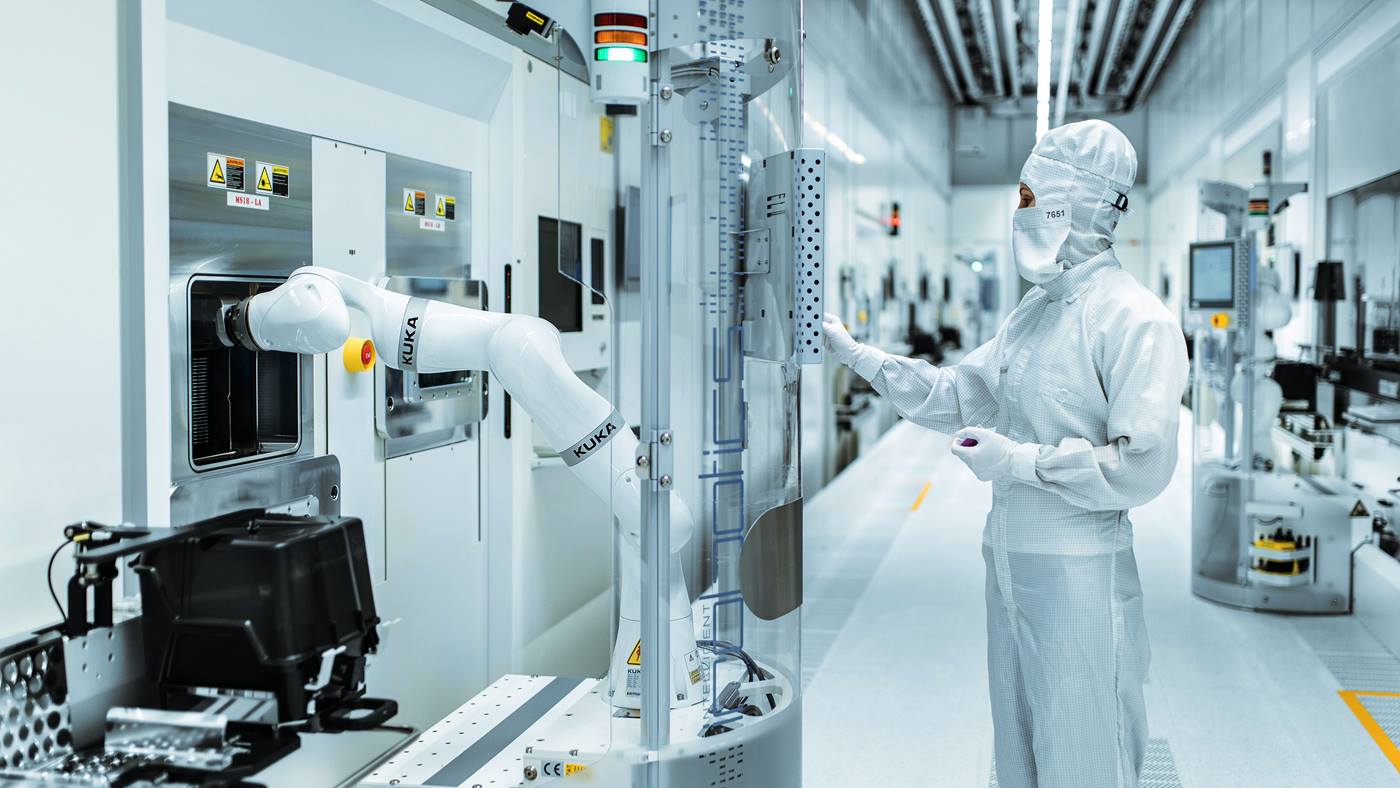

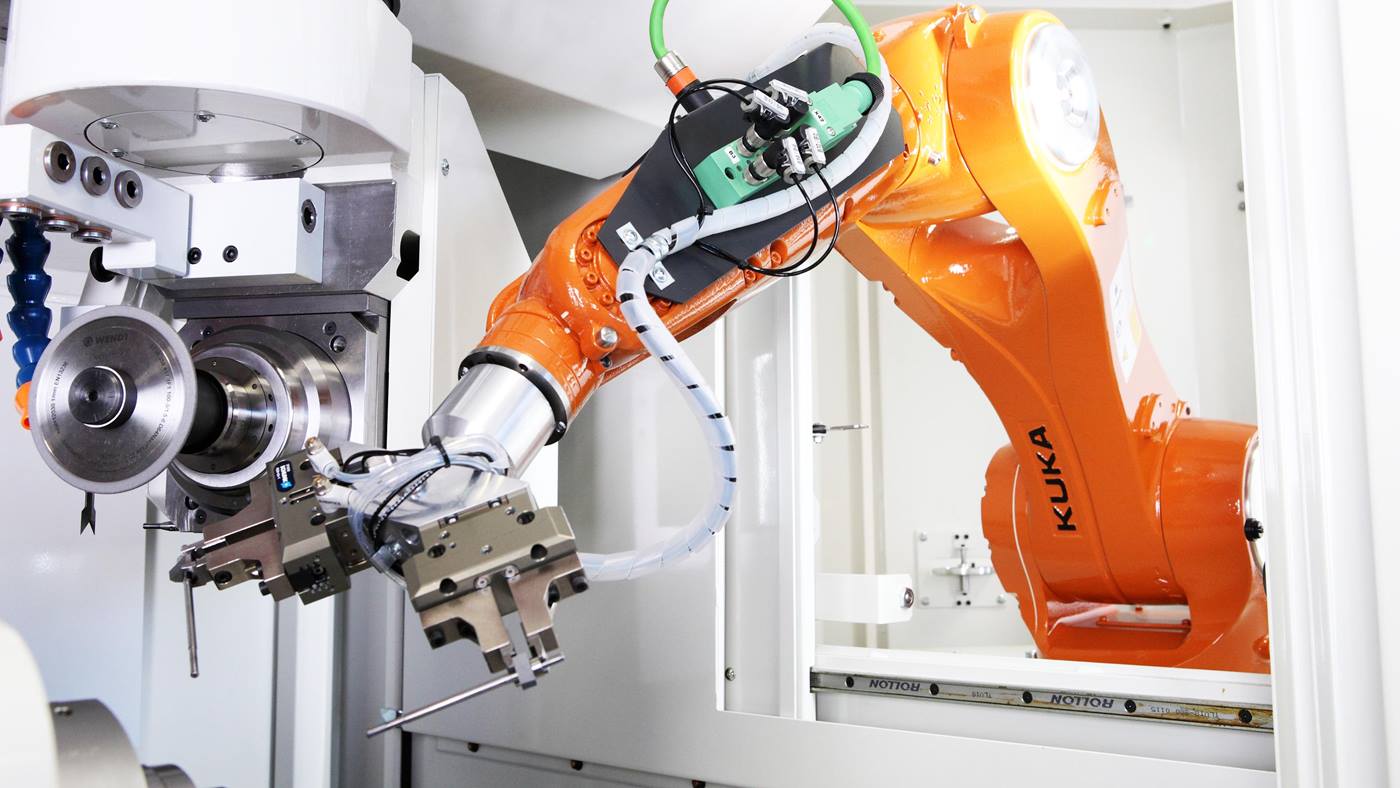

Sunstall eventually partnered with Cosmic Robotics, an AI-robotics company that produces the Cosmic-1A, an autonomous mobile robot designed to be a force multiplier for field construction. The fully electric robot incorporates a rugged all-terrain vehicle platform and a large KUKA robot arm equipped with a specialized end effector for lifting solar panels. “There’s an off-road UGV vehicle base that does the driving,” says James Emerick, CEO of Cosmic Robotics. “On top of it is the KUKA manipulator that uses a computer vision system that we’ve developed in-house to detect the position and orientation of the solar panel, pick it, and place it on the racking.” The robot places the solar panels onto the racking with ±1mm precision.

Selecting a Robot Built for Harsh Field Conditions

In looking for a robot supplier to partner with for this system, Cosmic Robotics had numerous features to consider. The system had to be robust enough to contend with varying environments that could include high moisture content, dust and rain. In addition to withstanding the elements, the robot had to be able to handle the 80-pound payload, even with the arm fully extended. Finally, it needed the precision necessary to lift the fragile solar panels and place them on the frames without damaging them. The company landed on the KR IONTEC robot arm as the perfect fit for meeting the precision, endurance and payload requirements of the job. “We went with the Foundry version because we needed the most rugged piece of hardware to be able to withstand the elements,” explains Emerick. “With the Foundry version we get the extended temperature range and positive pressure on the joints to keep out any dust and debris.”

Integrating Robots into the Installation Workflow

The job still requires a full crew to set up the frames that hold the solar panels, as well as people to fasten the panels to the frames, but the robot eliminates the tiring and physically challenging work of lifting the panels into position. “I don’t care who you are, picking up an 80-pound load over and over for eight hours a day will leave you physically exhausted,” says Kauls. “Having the robot handle that part of the process takes a huge burden off our crews.”

With the heavy lifting removed, the work becomes more sustainable for installers. With the robot performing the lifting and placement tasks, Sunstall’s installers can focus on fastening, alignment, and quality control. “In practice, the robot can place modules faster and more consistently than a fully manual crew,” Kauls explains. “That means our installers are no longer limited by fatigue over the course of the day.”

Improving Throughput and Crew Efficiency

After getting the Cosmic-1A up and running, Sunstall was able to significantly increase installation throughput while improving the overall workflow. “Before, we had a five-person crew handling transport, lifting, and installation,” Kauls notes. “With the robot taking over the lifting and placement, we can work with a smaller crew while maintaining or improving production rates. The efficiencies pay for themselves, and they only stand to improve.”

Looking Ahead: Fully Autonomous Panel Installation

Cosmic Robotics plans to use the same KUKA robot platform to develop a fastening solution that enables users to send the robot out with one or two operators while it transports, places and fastens each panel on its own. With the current version of the robot already outpacing human fasteners on site, this has the potential to create an even more efficient solar installation solution.

“This is good for us because we’re overall more productive,” Kauls says. “It’s good for our crews because they have fewer repetitive, straining tasks and allow them to use their skills elsewhere. Once means and methods are fully developed the technology will benefit the industry by reducing manpower for panel installation.”

A major challenge that has hampered the expansion of solar energy has been the time and labor needed to install these systems. With Cosmic Robotics and KUKA as partners, Sunstall is overcoming these limitations, and just in time to meet customer interest. Currently, the company has two more installations planned in Colorado and California, and demand is only growing.

More about the KUKA partner