Food automation: robotic solutions for any culinary challenge

Delivering raw materials, processing food, packaging, palletizing and preparing for dispatch - KUKA robots can do it all. With our holistic automation portfolio, you can master applications in the food industry quickly and efficiently.

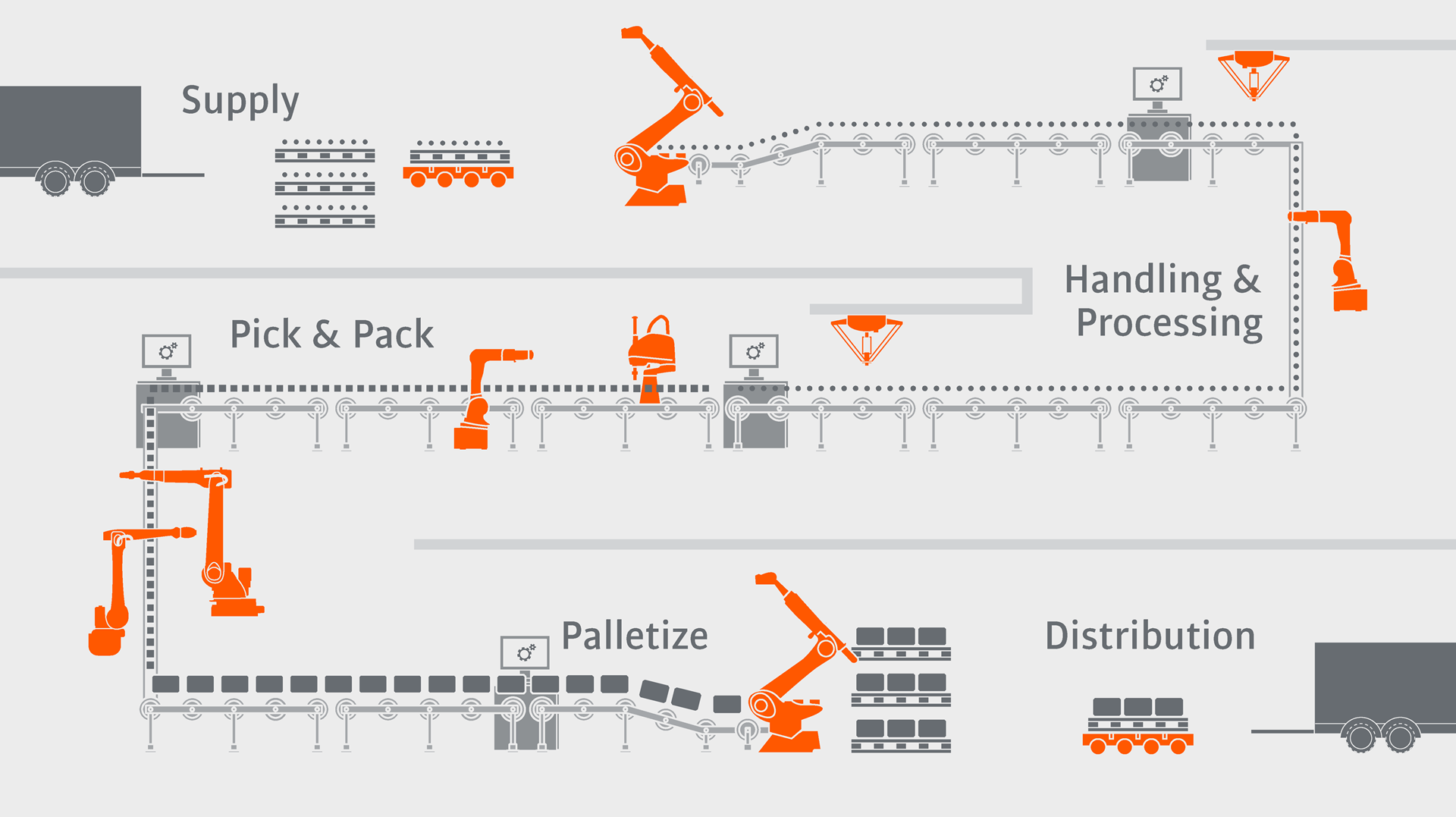

Flexible and smart automation across the entire food production chain

From delivery to distribution - worldwide

The process chain in the food industry usually starts with the delivery of the raw materials. This is where KUKA comes in - and, together with Swisslog, a KUKA Group company, and other partners, implements automation solutions for logistics processes, warehouses and distribution centers. In addition, KUKA automation technology can intelligently automate every other step in food processing and manufacturing. The advantages: higher productivity, low costs and consistently high quality in your process.

-

Delivery & depalletizing

Mobility, strength, long ranges

Our robotics solutions for you:

- Automated storage solutions from Swisslog

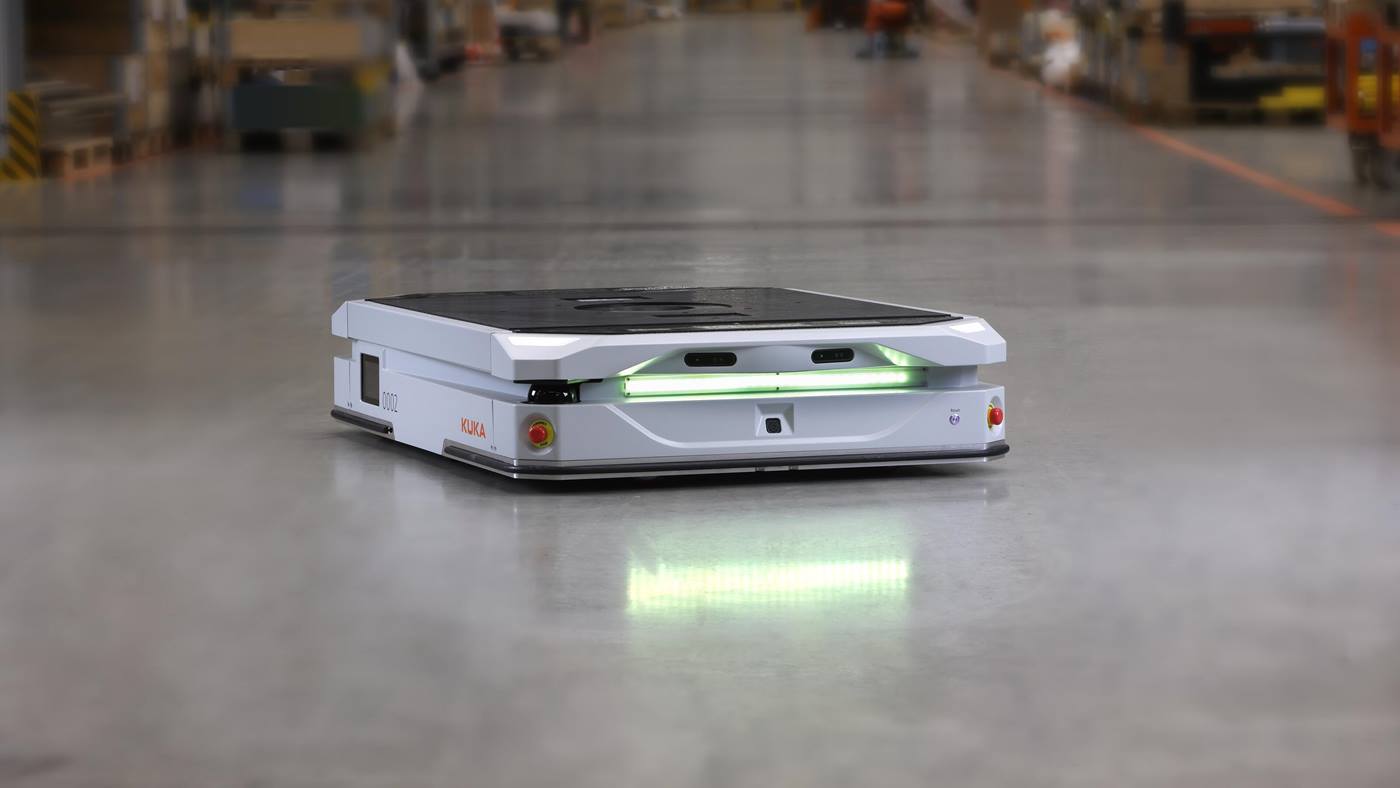

- KUKA Mobile Plattforms (AGVs)

- KR QUANTEC PA (120-240 kg Payload) – Fastest, most precise and strongest palletiser on the market

- KR FORTEC – Versatile heavy duty robots

- KR 360 FORTEC (240-360 kg Payload)

- KR 500 FORTEC (340-500 kg Payload)

- Linear units and portal robots – Allow space-saving automation of particularly large areas

Customer examples: Palletising of food -

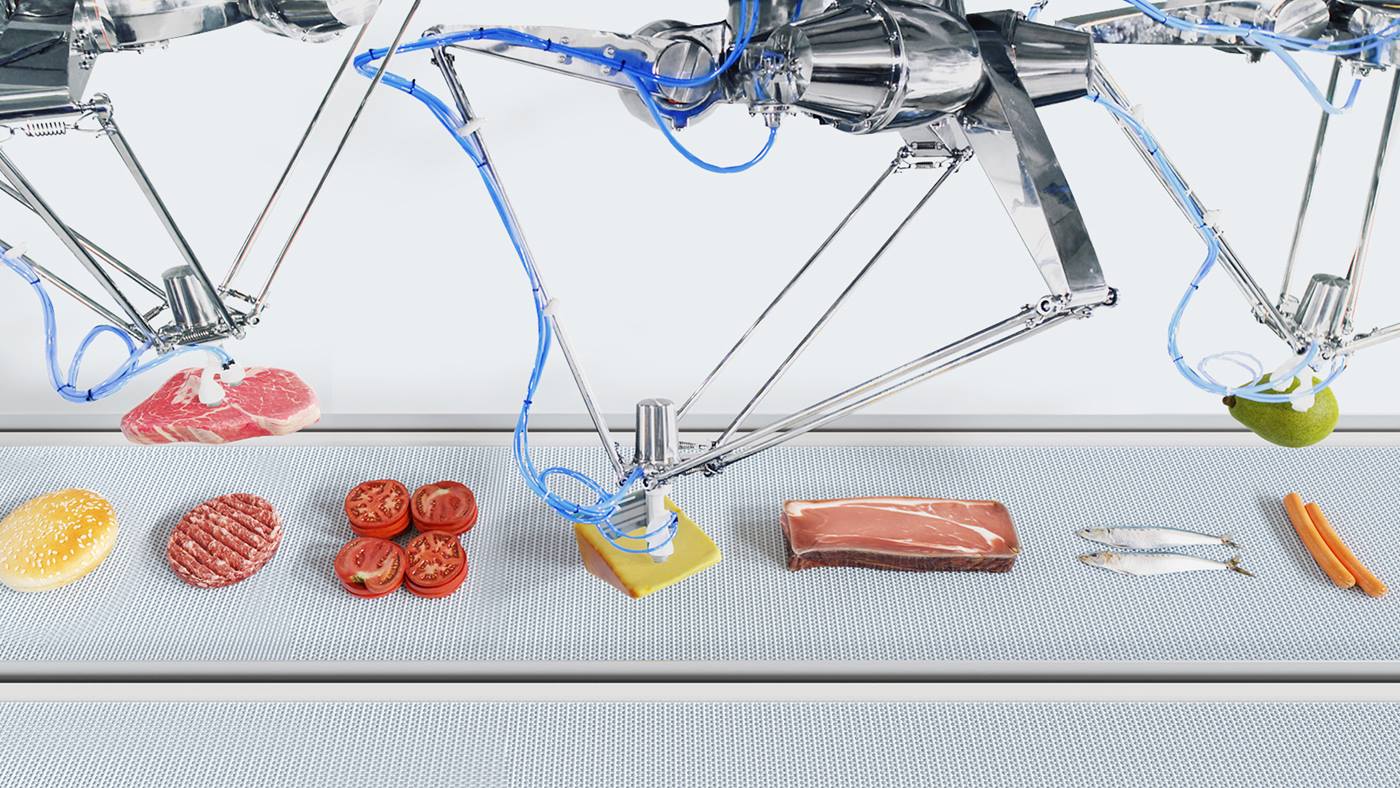

Handling of primary and secondary foods

Fast, precise, hygienic

Our robotic solutions for you:

- KR DELTA HM (3 kg payload), KR AGILUS HM (6-axis robot, 6-10 kg payload) - The robots in the Hygienic Machine design are made entirely of stainless steel, are easy to clean and disinfect, FDA certified components.

- KR AGILUS HO (6-axis robots, 6-10 kg payload) - The robots are built with food-grade lubricants in all axes, are easy to clean and disinfect.

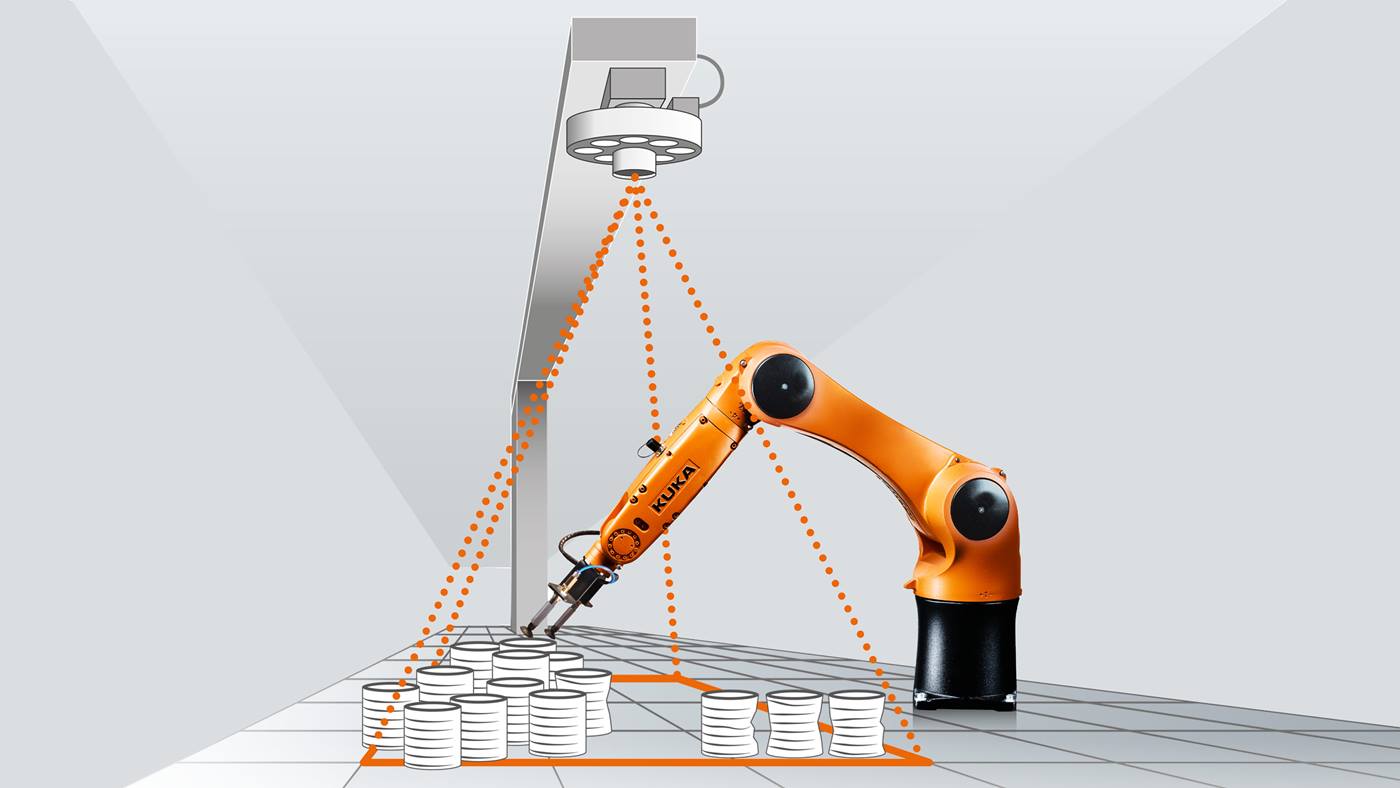

- KUKA.PickControl –Conveyor tracking software with integrated image processing.

Customer Examples: Food handling and processing -

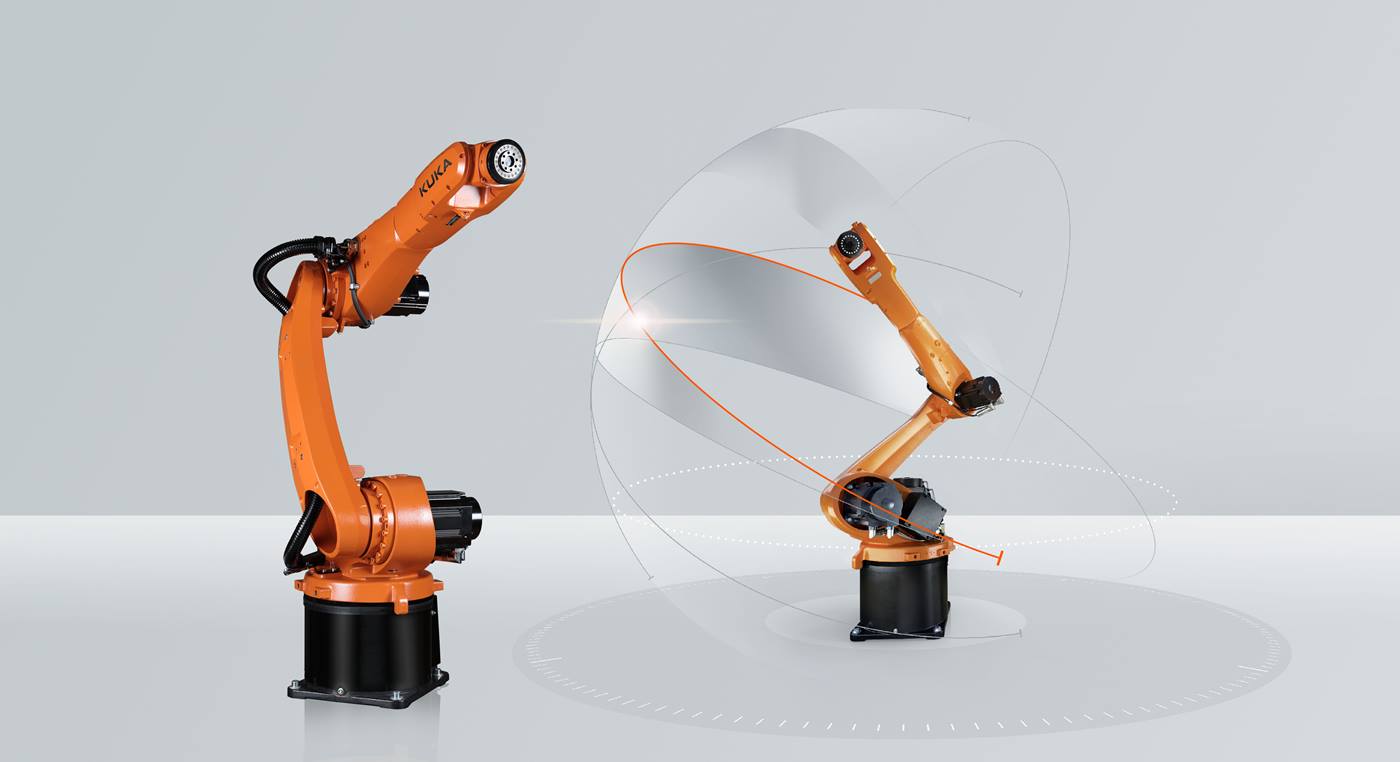

Palletizing

Extremely strong, fast, flexible

Our robotic solution for you:

- KUKA Palletizing robots:

- KR 40 PA ( 40 kg payload)

- KR QUANTEC PA (120-240 kg payload)

- KR 300 PA (300 kg payload)

- KR 470 PA (470 kg payload)

- KR 700 PA (700 kg payload)

- Linear units and portal robots – Allow the space-saving automation of particularly large areas

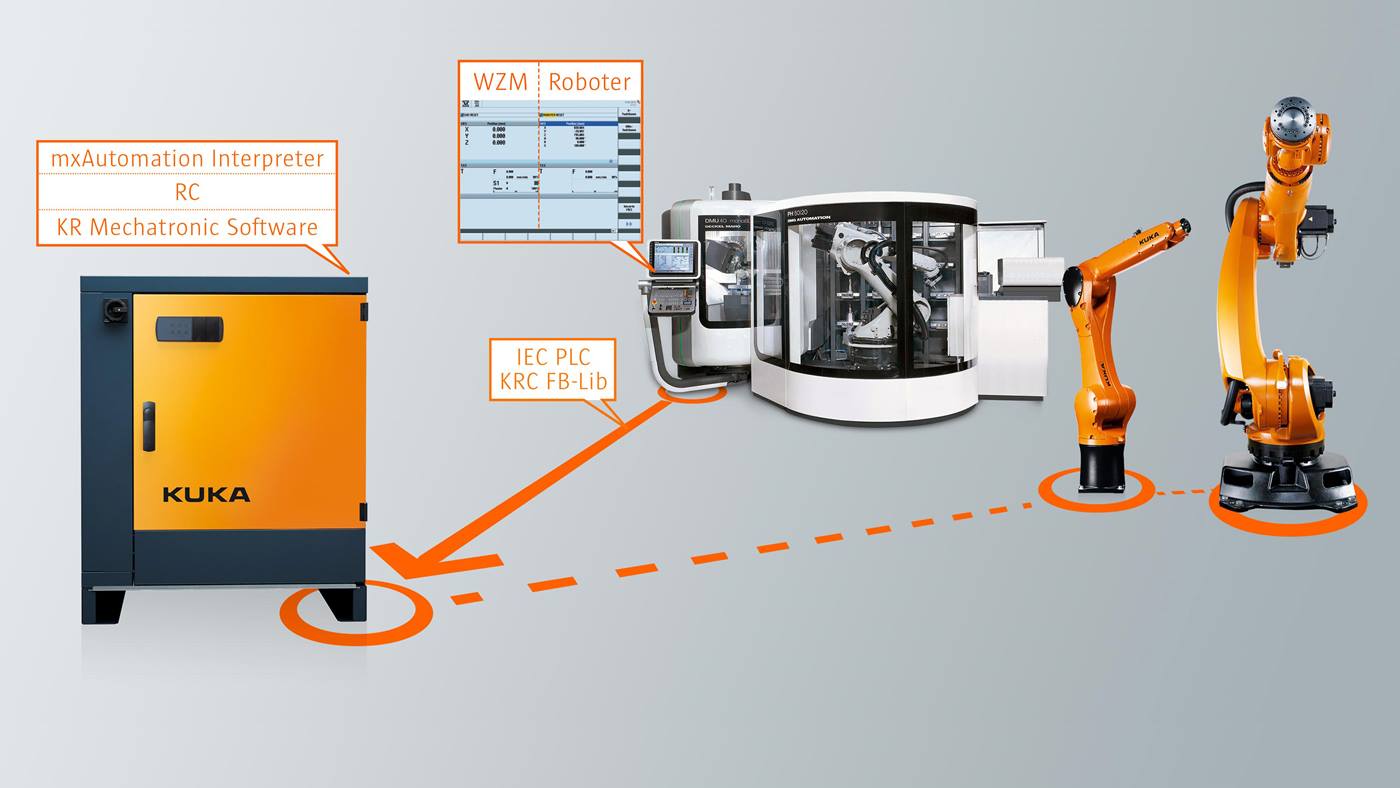

- KUKA.PLC mxAutomation – Software for the integration of robots into your machine network

- KUKA.PalletTech – Software allows easy configuration of palletizing tasks with different packing patterns and stations.

Customer examples: Food palletizing - KUKA Palletizing robots:

-

Pick and Place

Lightning fast, spotless, error-free

Our robotic solution for you:

- KR DELTA HM (3 kg payload), KR AGILUS HM (6-axis robots, 6-10 kg payload) - The robots in the Hygienic Machine design are completely made of stainless steel, are easy to clean and disinfect, FDA certified components.

- KR AGILUS HO (6-axis robots, 6-10 kg payload) - The robots are built with food grade lubricants in all axes, are easy to clean and disinfect.

- KR SCARA – Ultra-compact robots tailor-made for highest performance

- KMP 1500 (AGV) – Material transport in dynamic environments

- Standard robots for all installation positions – KR CYBERTECH (8-22 kg payload), KR IONTEC (20-70 kg payload)

- KUKA.PickControl – The software ensures optimum material flow.

- KUKA.VisionTech – Software for 2D object recognition, quality control and code and OCR recognition.

- KUKA.ConveyorTech – The software automatically adapts the robot actions to the movement of the flow and conveyor belts.

Customer examples: Automated pick & place -

Distribution

Fast transport, faster to the end customer

Our robotic solutions for you:

- Automated solutions from Swisslog

- KUKA Mobile Plattforms (AGVs)

- KR QUANTEC PA (120-240 kg payload) – Robots with food-grade lubricants in all axes

- KUKA.PalletTech –Software for simple and user-friendly configuration and execution of palletising tasks.

- KUKA.VisionTech – Software for 2D object recognition, quality control and code and OCR recognition.

- KUKA.ConveyorTech – The software adapts the robot actions to the movement of the flow and conveyor belts.

Customer examples: Logistic solutions

KUKA supports with comprehensive expertise - whether with technical support or process development

Based on many years of experience, KUKA offers extensive support and access to all the resources you need, including virtual or face-to-face training, easily available spare parts and much more. Plus, thanks to our global network of System Partners, we're always close by - and ready to help around the clock. We work with you to customize every aspect of your automation solution to your application requirements.

- 360° support: We accompany you throughout the entire life cycle of your robot automation system

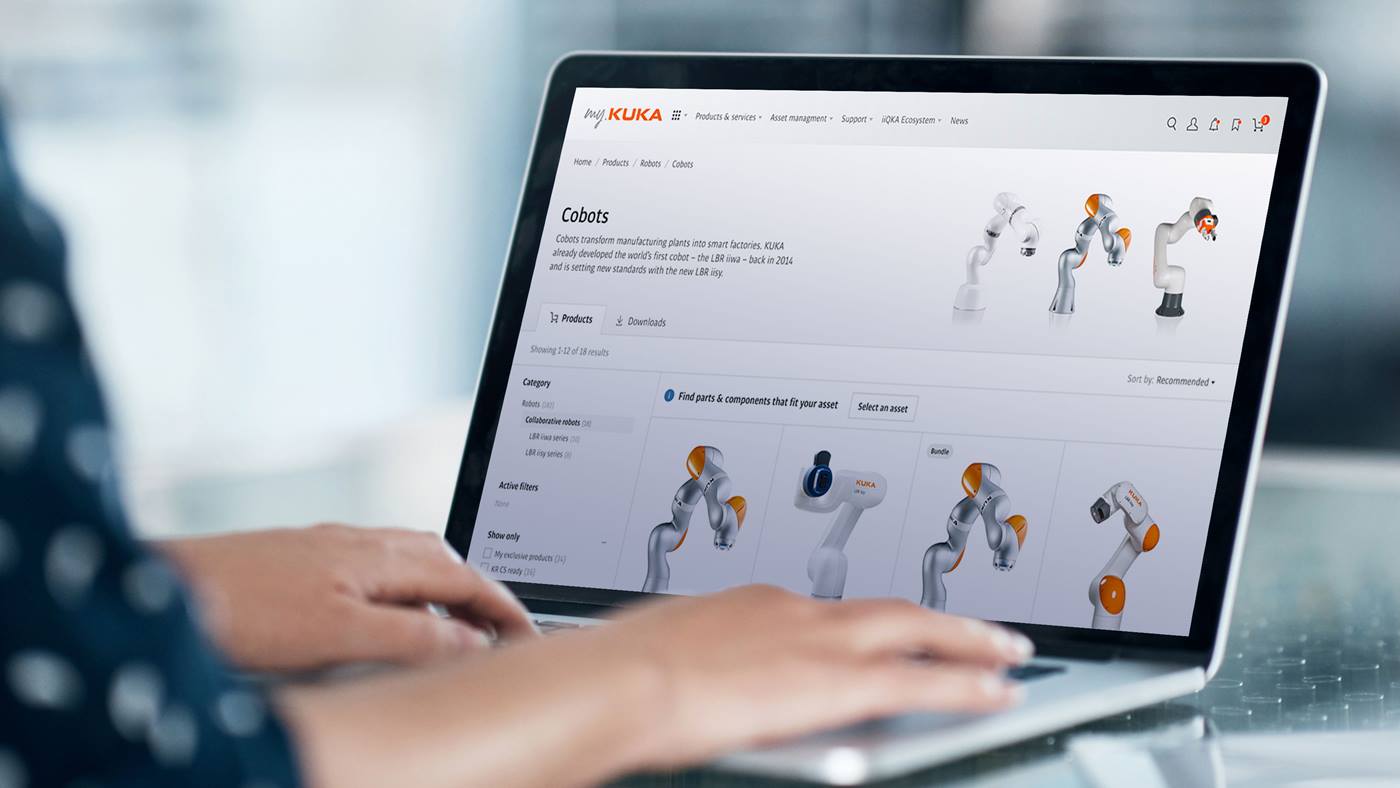

- my.KUKA: Your digital customer portal with 24/7 access to information and services

- KUKA Xpert: A digital knowledge database for all KUKA products, accessible at any time and from anywhere

- Remote Service: For safe and fast remote maintenance and fault diagnosis

- iiQoT: The central platform for monitoring, controlling and visualising robot fleets in real time