KUKA at CIIF 2017

With more than a dozen exhibits at this year’s China Industrial Industry Fair, KUKA showcases their latest innovative products and Industrie 4.0 solutions for intelligent production. See you from November 7 to 11 in Shanghai!

Important information for starters

Tha Augsburg-based automation specialist KUKA presents new products and innovations in the domain of automation and robotics at the renowned fair.

-

When: November 7 to 11, 2017

-

Where: National Exhibition and Convention Center, Shanghai, China –Hall 8.1, Booth D013

-

Booth size: 700 sqm

-

More than a dozen exhibits

-

Special VIP: meet table tennis master Timo Boll on November 7

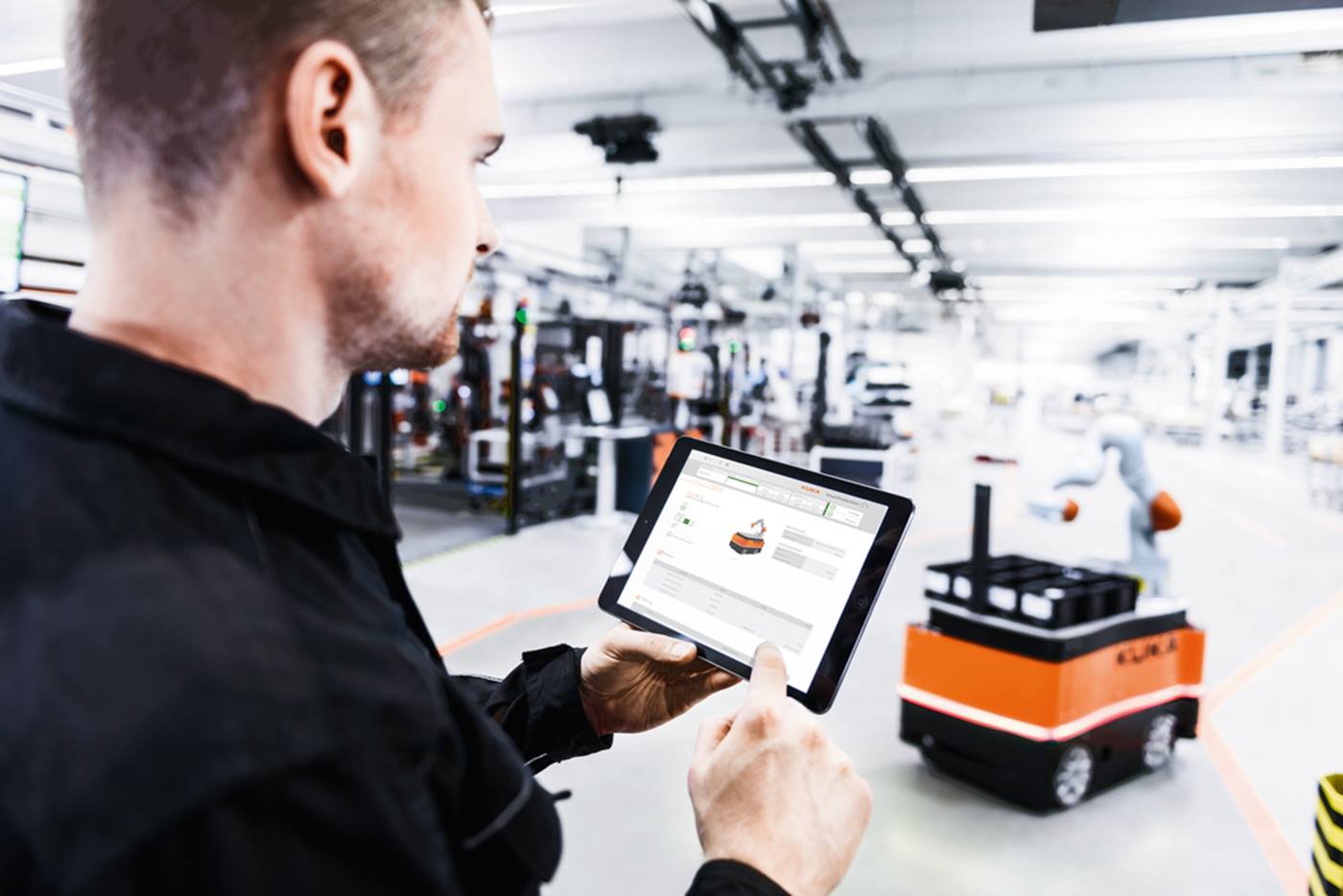

KUKA machining cell goes Industrie 4.0

KUKA connects the analog and digital worlds – and we'll show you at the fair how this looks in real life. In the exhibit, a robot collaborates with two machining centers to produce robot components. All active components of the cell – not just KUKA's – are integrated into the SmartProduction environment.

The data is then forwarded to the cloud so that operators and management have a complete overview of the production process, at any time and from any location. Meet our consultants directly at the booth and learn more about the advantages of going Industrie 4.0.

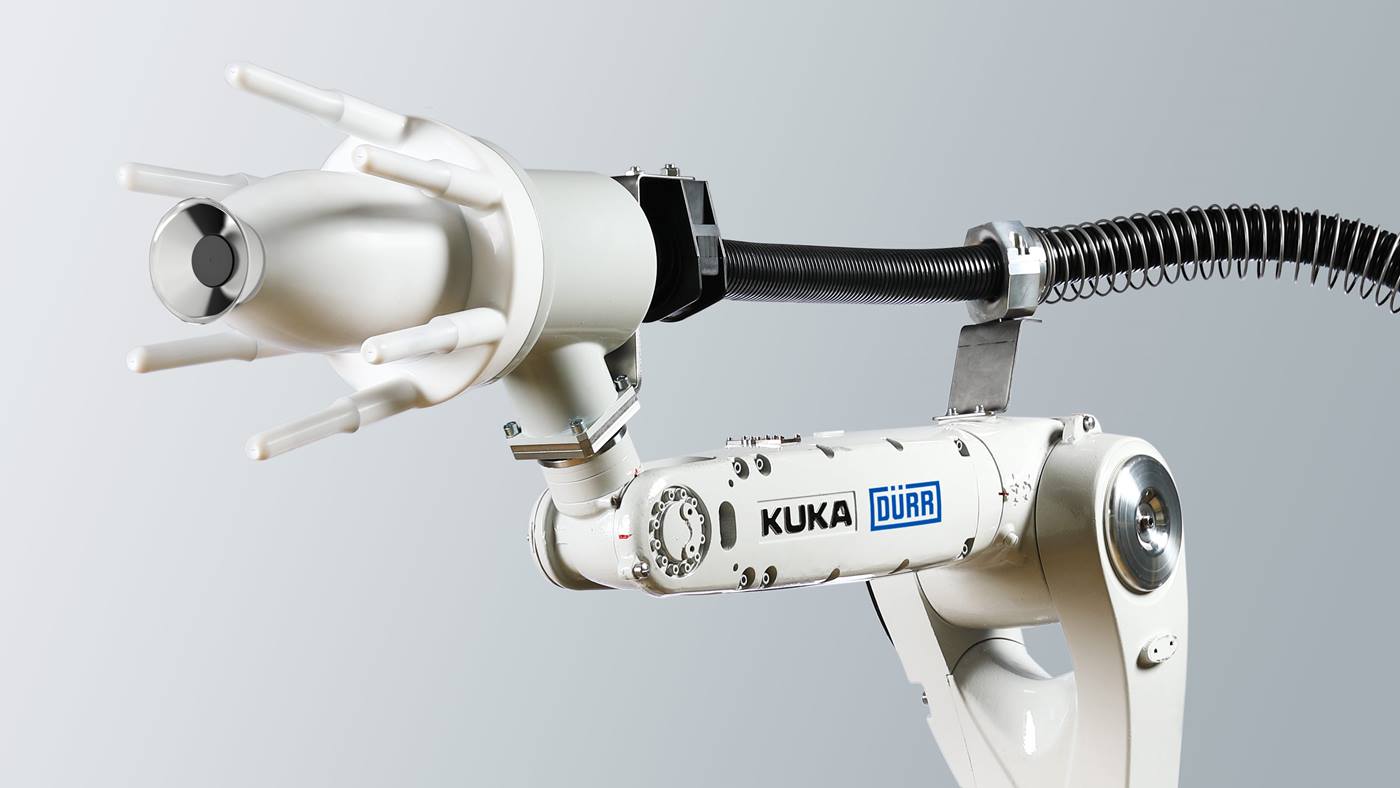

Powerful automation with ready2_use packages

You want easy access to automated manufacturing without extended or disruptive installation? Then you should get to know KUKA's ready2_use packages.

The preconfigured solutions enhance your productivity and efficiency and can easily be integrated into your shop floors. ready2_use offers the sum of KUKA’s deep experience and knowhow from across the industrial landscape. Come visit our booth and see them in action!

We'll show you on-site how our ready2_use packages can help you to automatically paint products and surfaces (ready2_spray), easily tighten micro screws (ready2_fasten_micro), allow easy control of a robot with no training required (ready2_pilot), provide preconfigured grippers (ready2_grip) or do arc welding with an extreme accuracy (ready2_arc_Kemppi).

Another highlight is the presentation of the facelift of the KR AGILUS robot family. Be there when we show our updated compact six-axis robots that are designed for particularly high working speeds.

Ready for the battery revolution

The demand for battery technology has risen dramatically as electrical cars, smartphones or homes with independent power storage are becoming more and more popular.

One of the particular challenges of this technology is the joining of hard-to-connect materials such as copper and aluminium. KUKA has been using proven technologies for years and showcases their competence in this field directly at the booth. Come visit us and get to know our specialized rotary friction welding machine RS1!

Solutions that make your production smart

We'll also exhibit our friction welding machine Genius in Augsburg – virtually through Hololens. Used in an application called KUKA SmartConnect.frictionwelding, this setup is nominated for the Industrie 4.0 Innovation Award 2017 and once more shows our competence in Industrie 4.0 solutions. Get to know this application in augmented reality and learn how it can make your production line fit for the future.

Another way to make use of the systems' data in the cloud is our Mobile Data Management (MDM) solution. Let us show you how MDM allows project managers, mechanics or electricians to access all relevant data from their mobile device, directly on-site.

Optimizing storage capacities with AutoStore

With AutoStore, logistics subsidiary Swisslog is presenting an innovative automatic small parts storage system.

The system improves the utilization of available storage capacities through efficient picking and warehousing: robots collect the required bins and present them at integrated picking stations. AutoStore is easy to integrate into existing buildings and future-proof thanks to the scalability of its strictly modular design.

At the booth you can find out at first hand about the possibilities opened up by augmented reality in the field of warehouse management.

Just put on the VR/AR Hololens headset and walk around our virtual warehouse where you can see the robots performing their impressive picking applications.