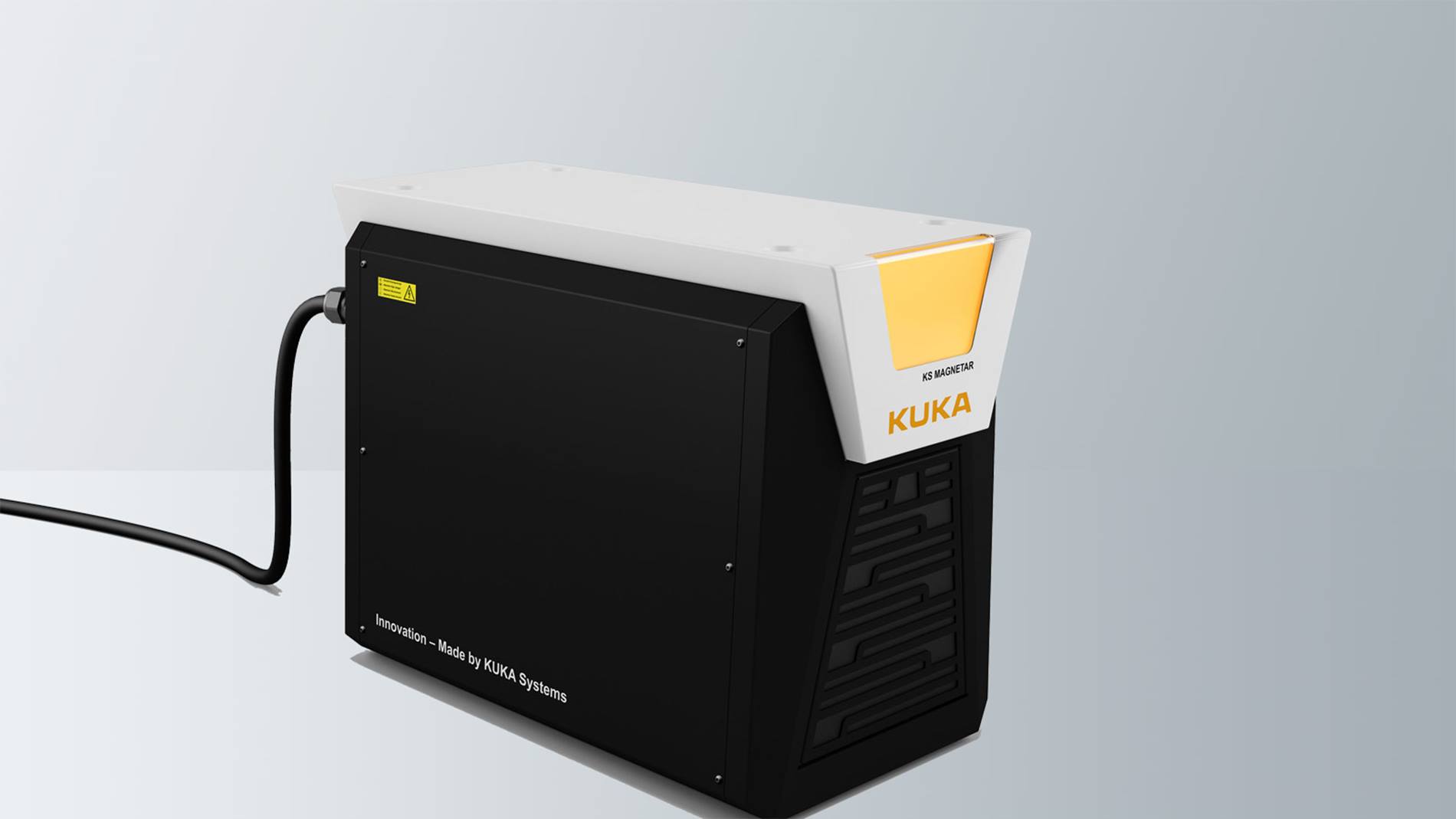

Advantages of the new MagnetAr 620A

Compared with its predecessor, the SSQ, the new KUKA weld power source is far more efficient and easier to use. Benefit from these advantages in particular:

Low energy consumption

Compared with the previous MagnetArc weld power source, the MagnetAr 620A uses up to 20 percent less energy. This makes it even more cost-effective.

Scalable solution

For higher power outputs, you can modularly expand the KUKA Magnetarc welding machine with up to four new MagnetAr 620A weld power sources.

Controlled process current

The controlled energy input with welding current from 0 to 620 A ensures maximum weld quality and reproducible results at the highest level. The process current is guaranteed, irrespective of the frequency and voltage fluctuations – with any mains supply anywhere in the world.

Simple service

In the event of servicing, exchangeability is 100 percent guaranteed. Thanks to the plug-and-play solution, there is no need for specialist personnel or a service assignment if the weld power source is to be exchanged. Exchanging the MagnetAr 620A takes less than 10 minutes. No adaptation of the parameters is required and production can be resumed immediately. That saves time and avoids unnecessary costs.

Thanks to our KUKA Remote Service interface, diagnosis, remote maintenance and future functional expansion are possible online.

Low space requirements

The MagnetAr 620A is much smaller than the previous weld power source – and 85 percent lighter than the predecessor SSQ. It is easy to transport and can be fully integrated into the Magnetarc welding machine and machine operation. You thus save precious production space.