Assembly, loading and inspection more efficient and precise

The rapidly changing market necessitates the unceasing improvement of precision and efficiency in production. To this end, KUKA has introduced automation solutions to help build a smart factory production line that aligns with Industry 4.0.

Power Bank Assembly Line

This fully automated production system integrates KUKA’s automation equipment such as 6-axis nano robots, 4-axis SCARA robots and KMP AGV. Intelligent logistics of AGV, fast visual recognition, fast pick-and-place, flexible assembly... these modular workstations, upon the application of FlexCube, constitute a mini unmanned smart factory.

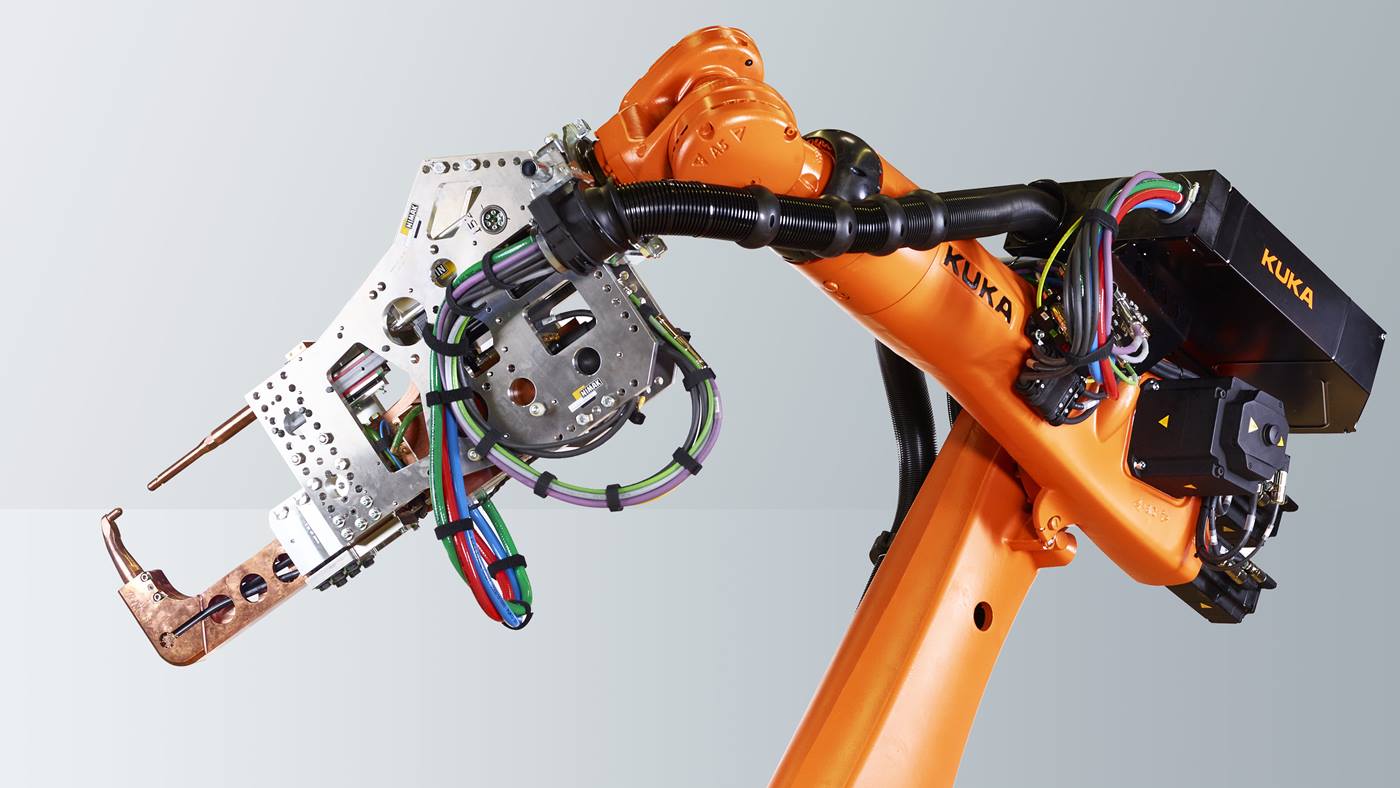

Cell Loading and Inspection Solution

The combination of KUKA robots and Schunk smart grippers makes it easy to detect cell thickness, width, OCV and DCIR. The smart grippers are equipped with a variety of sensors required for multiple detections during the process of cell loading. The modules in grippers are independent of each other for convenient repair and replacement.