Automated modular house construction

LBR iisy supports quality control

The future-proof storage system

When it comes to storage, flexibility is increasingly important for companies. This is also reflected in increasing demand for AutoStore Systems from Swisslog. At the electronics company Euronics in Estonia, 28 robots ensure that goods are delivered to customers four to eight times faster than before – time savings amount to two to three hours per delivery. Stationed at the central warehouse in Assaku near Tallinn, the system can handle up to 600 containers per hour and fulfill a customer order within 20 seconds.

Saving lives: the right medication at any given moment

With its “Closed Loop Medication”, Swisslog Healthcare has created a management system that records and organizes medications. Together with TheraPick, the intelligent unit dose packaging, storage and picking system, it serves to increase patient safety.

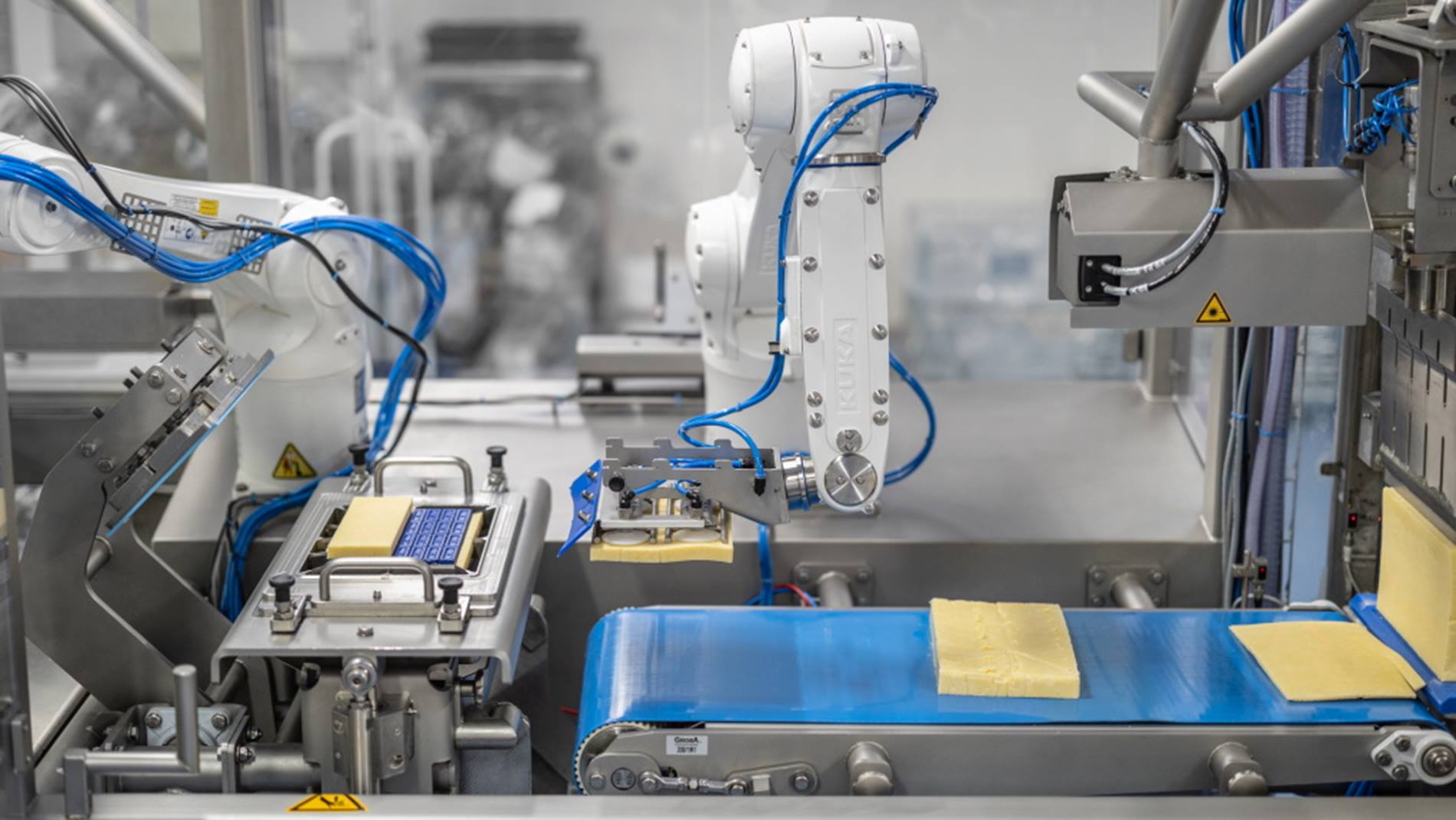

Robots in the food industry

Robots as harvest helpers

New solutions for new markets: a robot for automated apple harvesting. Because many owners of the 4.9 million hectares of apple orchards worldwide, an area larger than Switzerland, lack harvest workers. The KUKA CropBot steps in: a vision system with vacuum suction picks the apples from the tree and packs them. The automation potential is huge; for the apple harvest alone, 1.6 million robots could be used globally.

Shaping the future of work

Cobots can provide support with a view to the future of work. What's more, they can make a positive contribution to the well-being of employees. As in the case of Dietmar, who can only move his shoulder and wrist to a limited extent due to health problems. With "Robbie's" help, a KUKA LBR iiwa, he can continue his nearly 30-year career. Together they work on the assembly line for engine blocks at Ford.

Robots in the textile industry

From plastic waste to designer piece