KUKA Customer Service configures robot system for packaging

You are using Internet Explorer and will not be able to use our website properly.

Please change to an up-to-date browser for ideal presentation of the website.

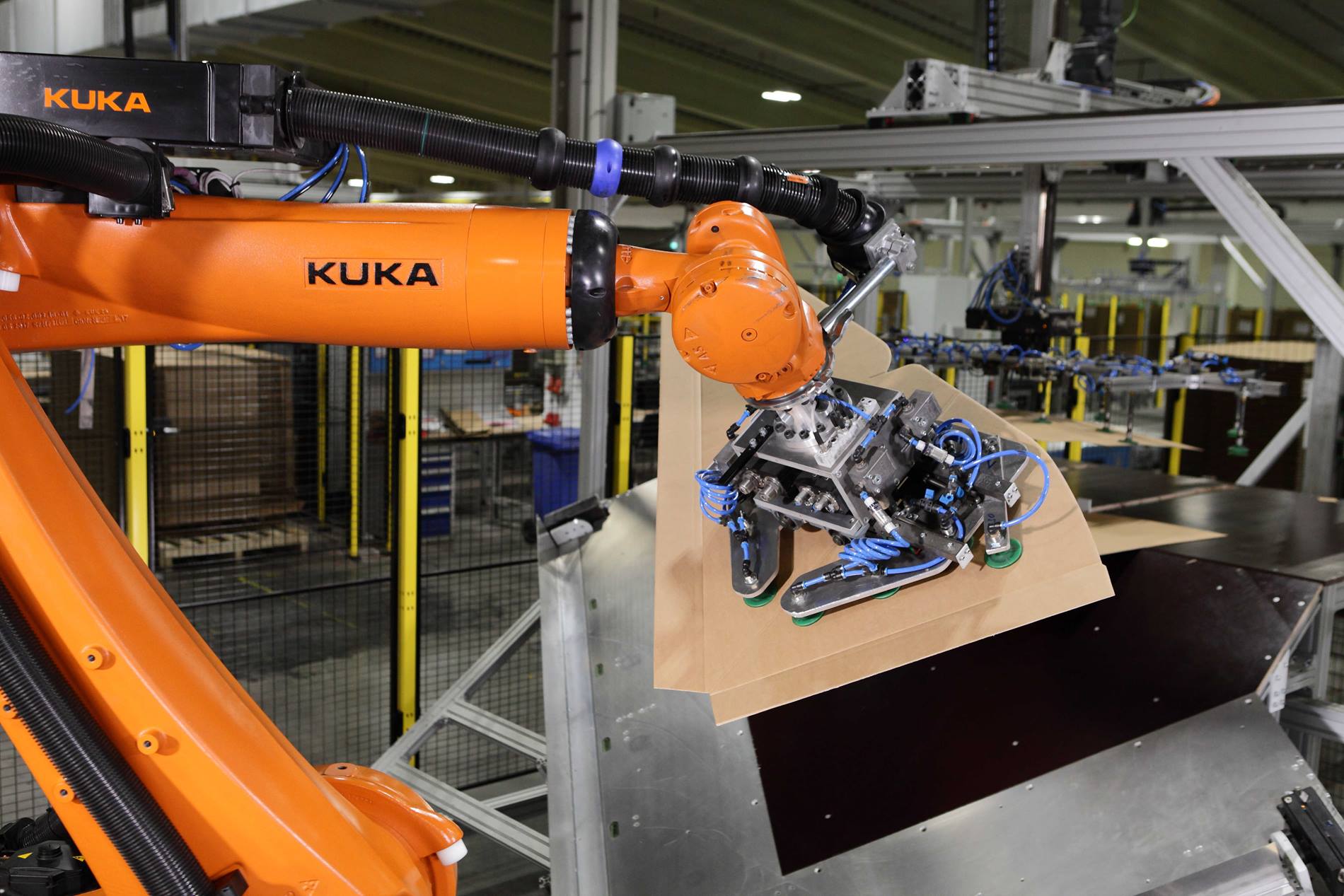

Around three dozen KUKA robot systems support Tricor Packaging & Logistics AG in the automated assembly and folding process of industrial corrugated packaging. Thanks also to KUKA Customer Service, seamless execution is possible.

A while back, this seamless execution was standing on the brink. The service provider commissioned to develop a special system was not able to complete the project. The company was at risk of not completing its system. “All at once, we needed the support of specialists,” remembers Lothar Heinzelmann, Engineering Projects Manager at Tricor.

The most recent joint project between KUKA and Tricor is a sensitive KUKA LBR iiwa robot used for folding and stapling corrugated blanks. The corrugated sheets are fed to the lightweight robot’s workspace. The sensitive robot takes the corrugated blank with a gripper and folds it along the predetermined break line. In the next step, it positions the blank in a holder and folds a square shape. The robot feeds the folded piece of corrugated board to a stapling device. The folding robot subsequently places the stapled part on a setdown station.

Tricor is highly satisfied with the results of the cooperation. The ‘first-aid response’ has developed into a long-standing partnership between both companies. “As a result of our service agreement, we remain in close contact and have already developed twelve further packaging systems together,” says Lothar Heinzelmann. The robots take over the folding of the corrugated sheets with a high degree of reliability in three-shift operation and relieve the employees of monotonous tasks.