With an extensive range of comprehensively integrated hardware and software as well as technology-based services, the Digital Factory (DF) division helps production companies all over the world to boost the flexibility and efficiency of their manufacturing processes, and to bring new products to market faster. At the site in the town of Bad Neustadt an der Saale, Siemens operates a lead factory for electric motors.

There, among other items, the motors for numerous KUKA robots are produced. With the expertise derived from hundreds of thousands of electric motors and employing a workforce of about 1,700 people, the lead factory is an innovative example of high-tech with the “made in Germany” cachet. Now, Siemens’ motor production in Bad Neustadt is receiving support from the flexible LBR iiwa lightweight cobot, which is capable of working hand-in-hand with its human colleagues.

Automation of workpiece handling

For its stator manufacturing operation, Siemens in Bad Neustadt was on the lookout for a flexible solution to automate the simple activity of passing on and positioning workpieces which had previously been done by hand – while retaining the high quality and continuous, barrier-free access to the working area for people.

LBR iiwa works autonomously and cooperatively

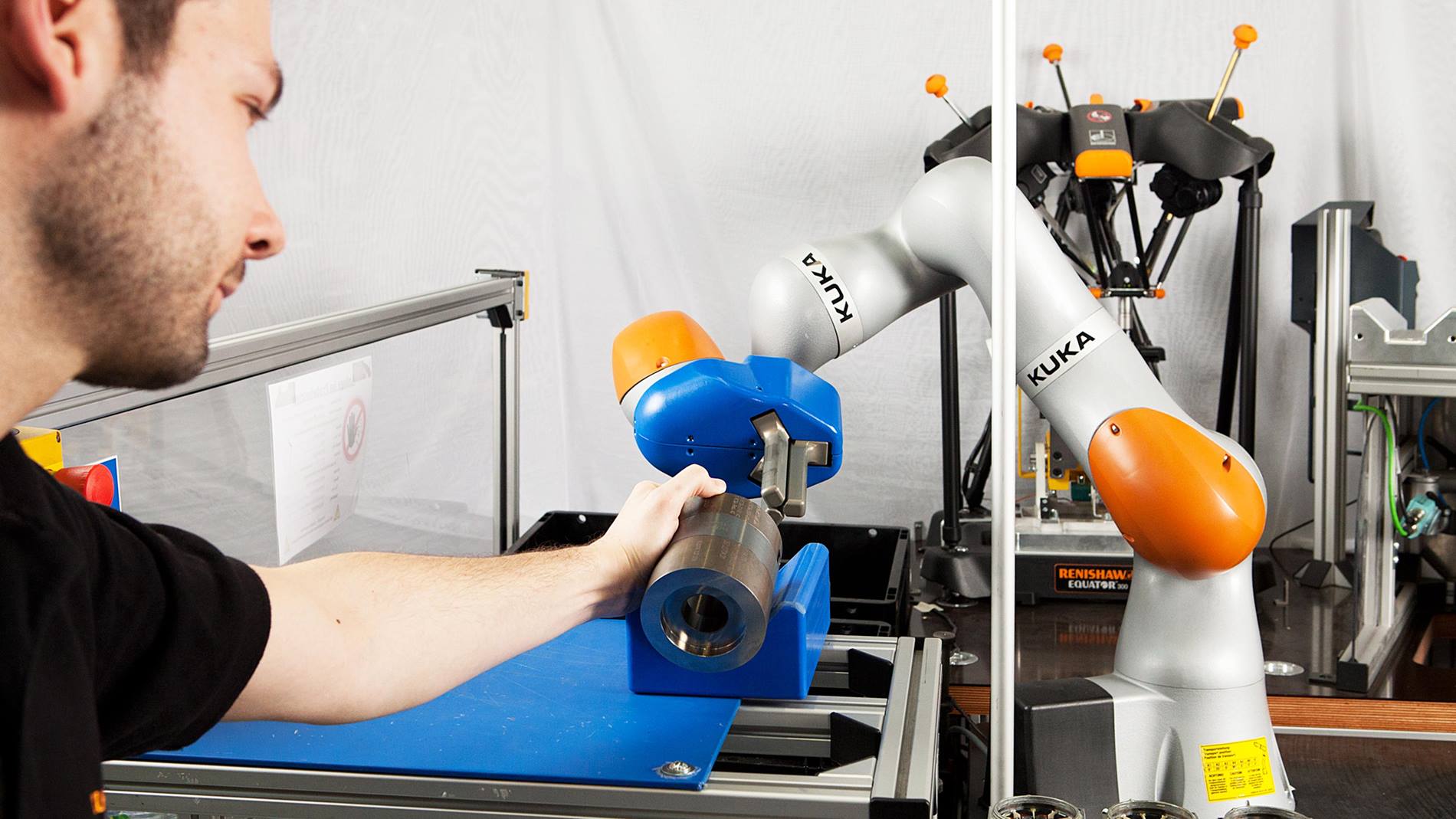

Together with the Augsburg-based company, KUKA Systems GmbH, and its Advanced Technology Solutions department, Siemens developed a flexible cell for this application using LBR iiwa lightweight cobot. In the Siemens plant in Bad Neustadt, the robot functions as a roving multitasker (Knight) mounted on a carriage with the task of taking the part to be processed – the stator consisting of a basic body made from punched magnetic steel sheet and an aluminum bearing plate – out of a workpiece carrier and supplying it to a lathe for machining the stators.

But that is not all: the robot is also used for the quality check. It grips the machined parts and scans the barcode. After the workpieces have been cleaned by blowing them with air, the lightweight robot feeds them to the measuring station in a tilting device.

If there are any deviations, they are found there. Thanks to networked technology, precise measurement and identification of each component makes it possible to calculate immediately whether a correction is required, and this can be implemented in the system. In line with the Industry 4.0 philosophy, the system consequently organizes itself.

After that, the robot places the part in a plastic box so it can be delivered. Parts that have to be recalibrated in the machine are placed into a buffer that is defined as the “HRC zone”, for human-robot collaboration. Here, the safe technology means the worker can be in the same area as the robot and, if required, remove some of the workpieces or change them.

No protectice fence thanks to collaborative robotics

Thanks to its sensitive capabilities and weight of less than 30 kilograms, the LBR iiwa lightweight cobot used by Siemens is ideal for collaboration between humans and machines. With its seven axes, it is not only more agile and more mobile than most models of its kind, it also features torque sensors in all axes, making the robot sensitive – as a result of which it can also detect obstacles in the room and respond accordingly.

In this way, KUKA is proving that robot automation and high flexibility are not mutually exclusive. Using sensitive robot technology makes human-robot collaboration possible. As a result, the enclosure that used to be required can be dispensed with, as can additional sensors for parts detection.

A successful and flexible solution

As a result, the decision was taken to use a flexible LBR iiwa lightweight robot combined with the KUKA solution of a “Knight concept”. This allows the robot to be deployed or simply moved away depending on the situation. Torsten Franz, project manager in the technology development team, adds: “An HRC application was also something new for us. We wanted to use the system as a learning tool ourselves, allowing us to bootstrap our development incrementally. This has been very successful in the joint project with KUKA. The solution is convincing.”