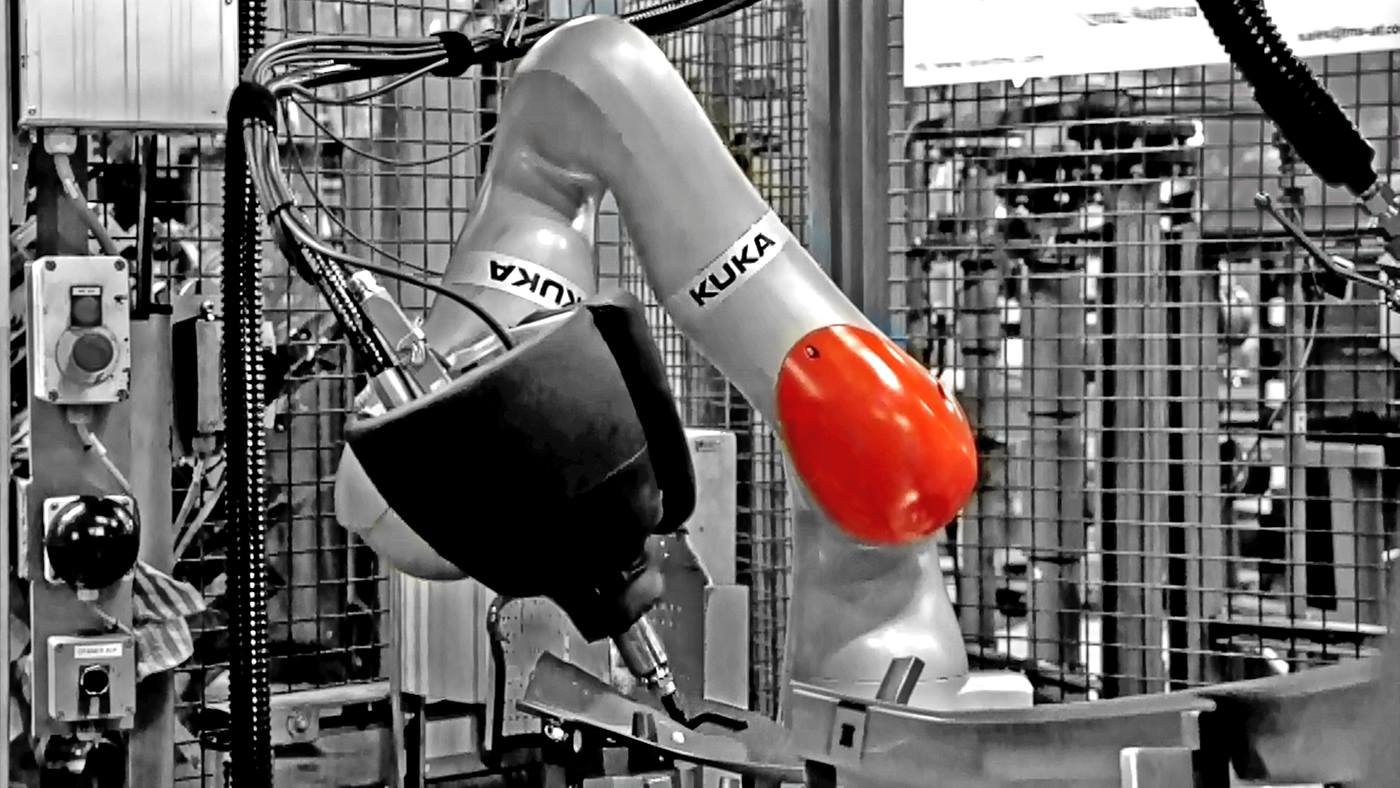

Human and cobot: a merging of workspaces

Human and cobots work hand in hand. A scenario that would have been utterly unthinkable a few years ago can now be implemented. In this way, many monotonous tasks that are burdensome to humans can be automated using a robot. So-called human-robot collaboration (HRC) is increasingly finding its way into production shops. The robot assistants are not yet part of the typical body-in-white production setup. The industry is currently undergoing a major change. Companies that wish to remain competitive must not only push ahead with digitalization, but must also automate and improve their production processes.