Stronger robot arms especially needed

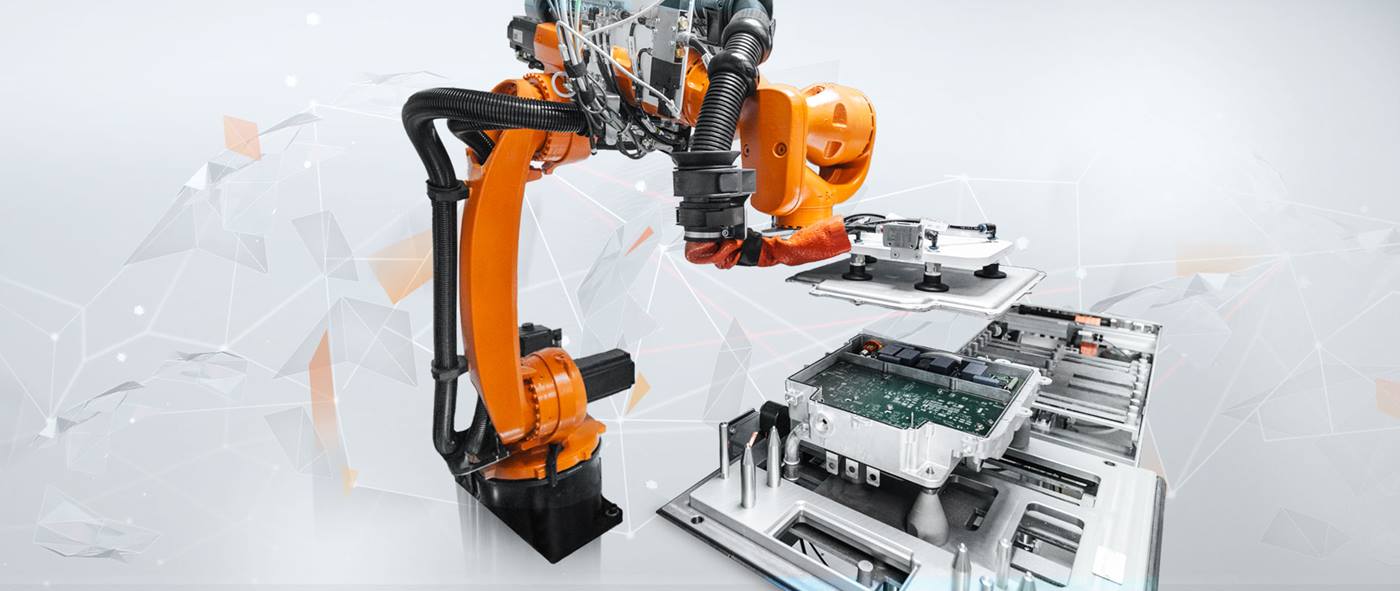

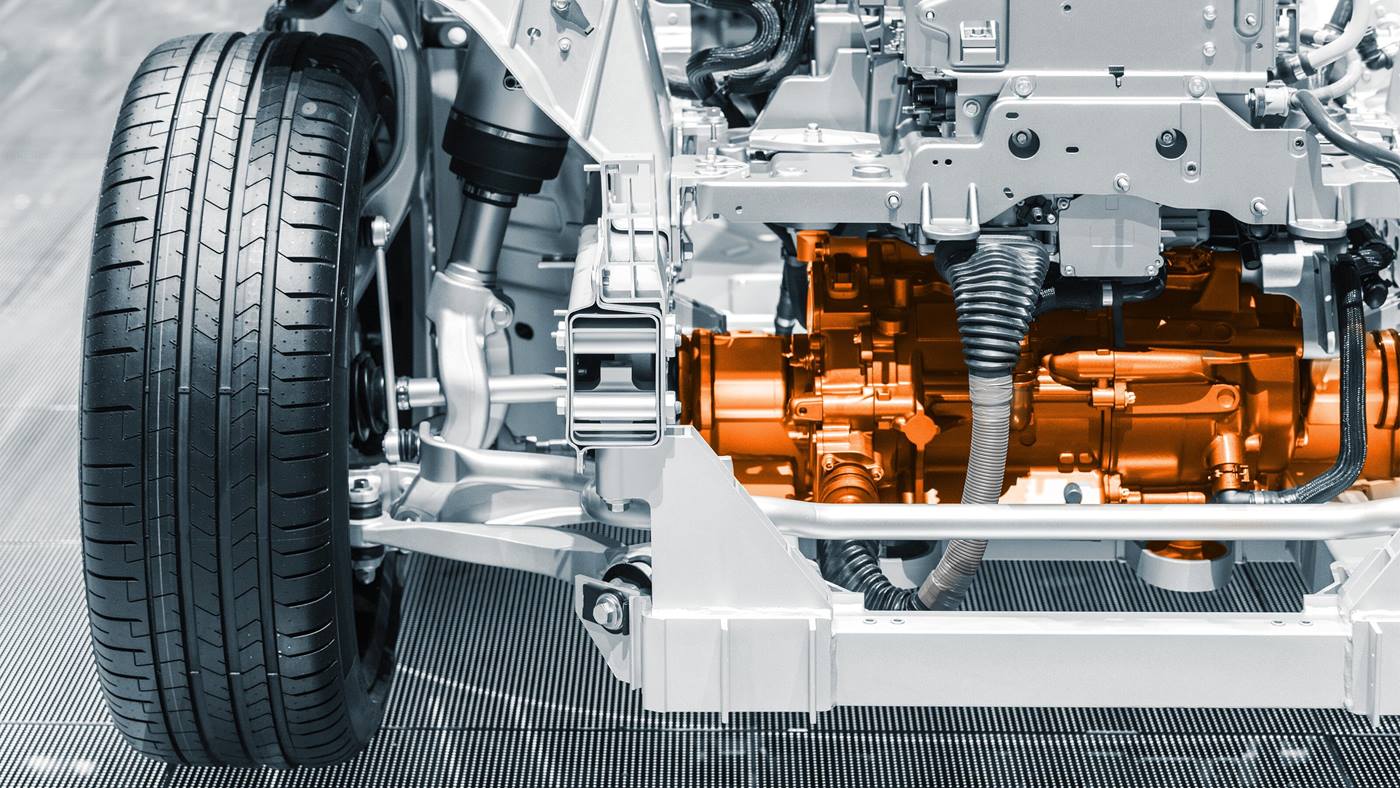

Scara robots, which cover the payload class up to 10 or up to 12 kilograms, are currently particularly needed in Asia. However, demand for an industrial robot of this type is also increasing in other regions of the world. Whether in electromobility, for example, stacking in battery production, for manufacturers of photovoltaic systems, in the assembly of components or in the packaging of medicines: These robots with their four axes are versatile in automation and pick-and-place tasks.

The KR 12 from KUKA therefore now fills a gap in the market and is eagerly awaited, especially since the KR SCARA series offers the same advantages for any payload: the shortest cycle times, high repeatability, compact design.

KUKA robots with highest speed

Both the SCARA KR 12 standard model and the KR 12 robots for the cleanroom are available in three different reaches up to 850 millimeters. At a reach of 650 millimeters, the cycle time is just 0.40 seconds, and at 850 millimeters 0.42 seconds. The KR SCARA thus stands for maximum efficiency, and this at temperatures from 0 to 45 degrees Celsius. At 50 kilograms, the KR 12 has a low weight for greater flexibility.

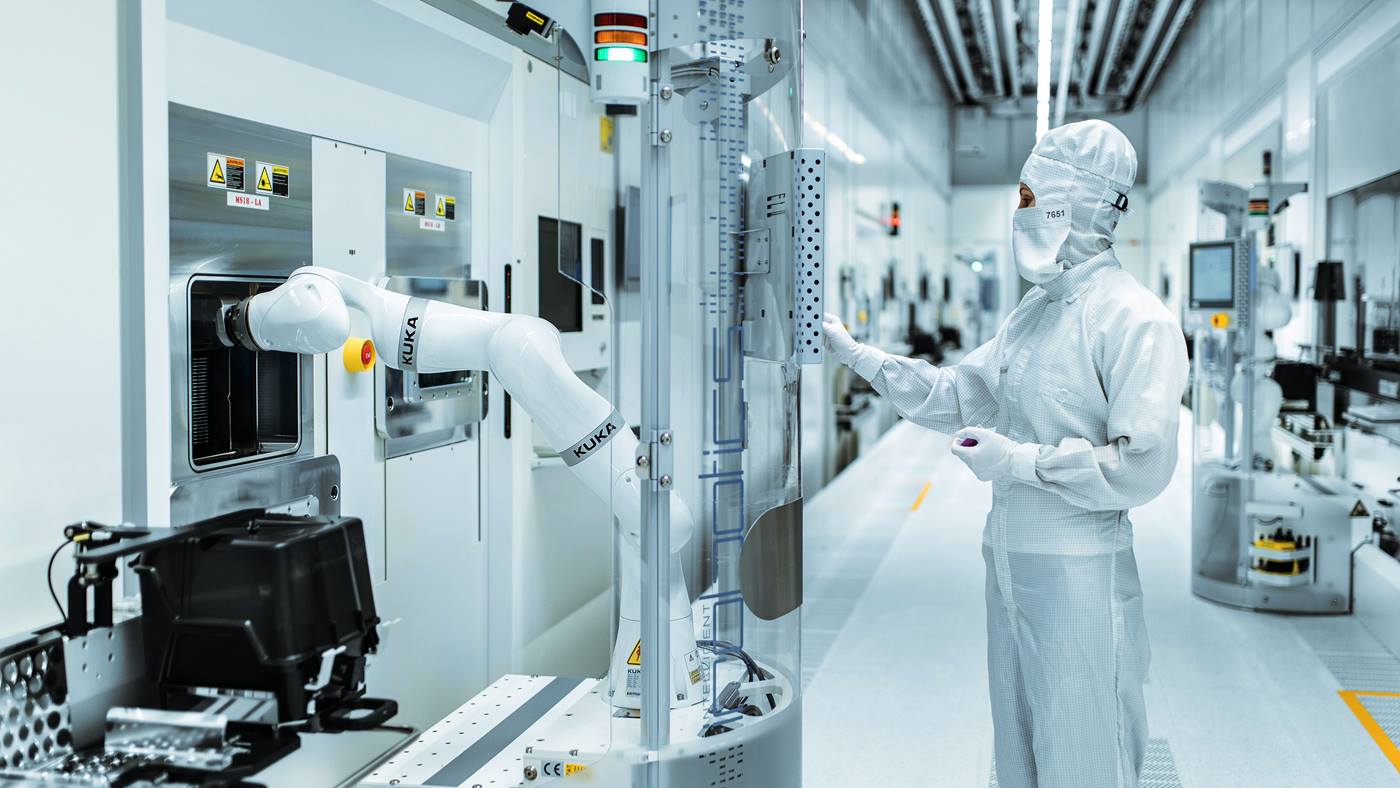

Suitable for clean room application

The fact that the cable routing runs inside the KR 12 makes it extremely compact and easy to clean. The standard versions comply with protection class IP20, the cleanroom versions with protection class IP54. This means that customers in the pharmaceutical industry, for example, benefit not only from the increased payload. Low maintenance requirements also meet market demands.

New Scara model from KUKA

Certified for high safety in almost any application, all versions of the KUKA KR 12 can be ordered from mid-July 2022. From mid-October 2022, the robots with the higher payload will then be ready to start work for manufacturers all over the world and further advance automation.