The modular component range from Wieland Anlagentechnik enables the optimal structuring, precise planning and reliable implementation of complex processes. This also applies to their latest application: the development, on the basis of customer requirements, of a system concept for pointing and then hardening copper profile rods for further processing on drawing benches. The copper rods are pointed by means of a KUKA robot that guides a MEBA band saw.

Solution wanted for varying material thickness and cut direction

„A solution was needed for the complete automation of the pointing process,“ explains Andreas Wiedmann, Head of Development, Marketing and Sales at Wieland Anlagentechnik. „The workpieces cannot be aligned when clamping in the machining position, but only secured in place. This made it necessary to adapt the saw cuts to the spatial position of the workpiece, with both the material thickness and the direction of the saw cuts varying in the course of the process.“ Compared with the previous semi-automated solution, a marked ergonomic improvement for the workforce was also required. “In order to be able to perform the saw cuts freely and independently in space, a solution with a robot was the only option that we considered,” adds Wiedmann.

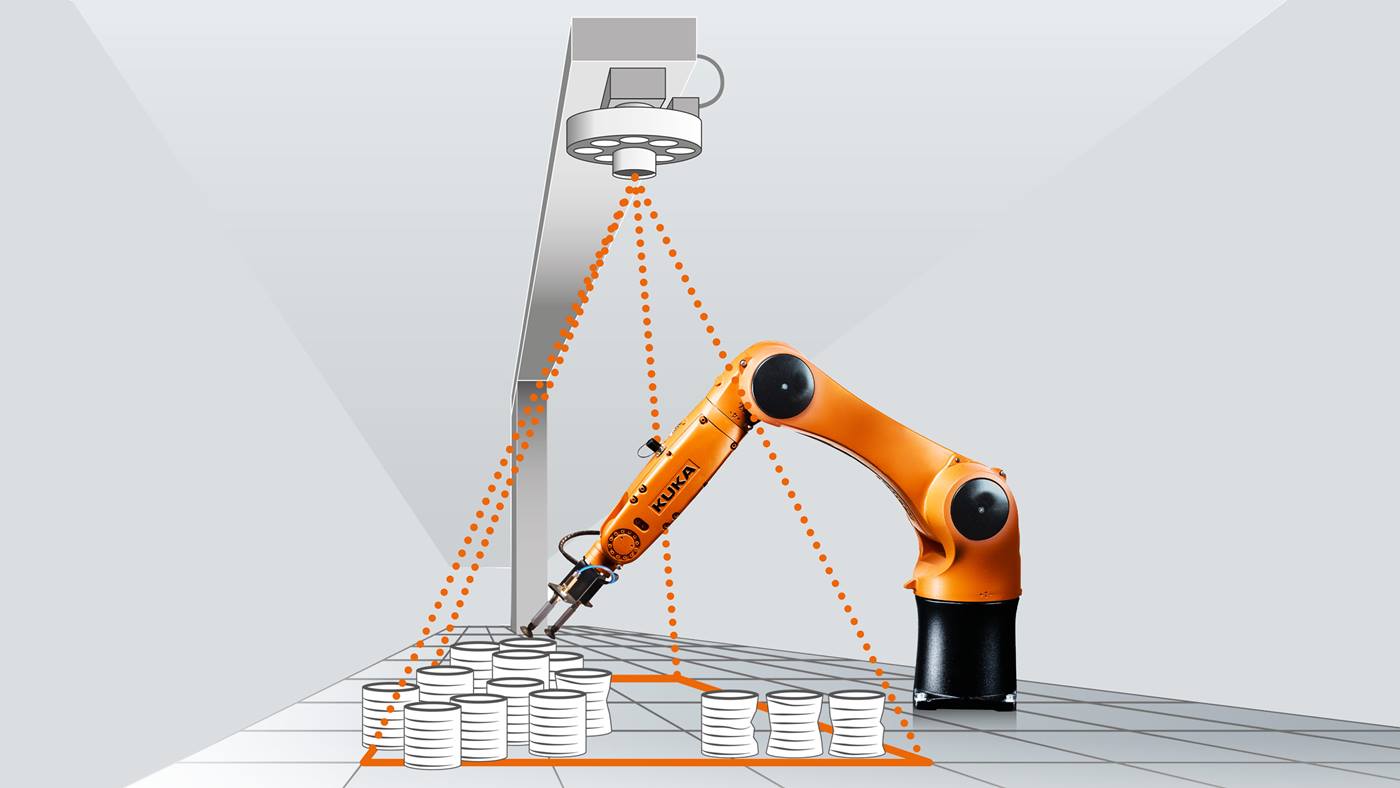

Image processing system detects workpieces

The six axes of the industrial robot provide maximum flexibility compared with other automation solutions. At the same time, the robot was to have high path accuracy and a stable, low-vibration structure. The demanding requirements on recognition of the copper workpieces necessitated prior tests. These were conducted in the KUKA Roboter GmbH test laboratories. From the first feasibility study through to on-site integration support, image processing experts were on hand to assist the KUKA Engineering department at all times.

The bundle of profile rods is first fed into the system and then separated by the operator with the aid of a manipulator. This is followed by onward transportation to the position of the clamping fixture into which it is fed by means of a roller track. In order to detect the exact position of the copper profiles, Wieland Anlagentechnik uses the KUKA.VisionTech system installed on and guided by the KUKA robot.

The data from the camera system are forwarded to a host computer, interpreted by the software and then output as a 3D sawing curve – a process which, prior to the automated solution, was still carried out manually by means of written markings. The saw cuts are defined on the basis of CAD data and transferred to the KUKA robot. The robot then performs four space-oriented, curved cuts with the band saw. In the next step, the resulting pointed core is oriented in space and rolled to harden the soft copper.

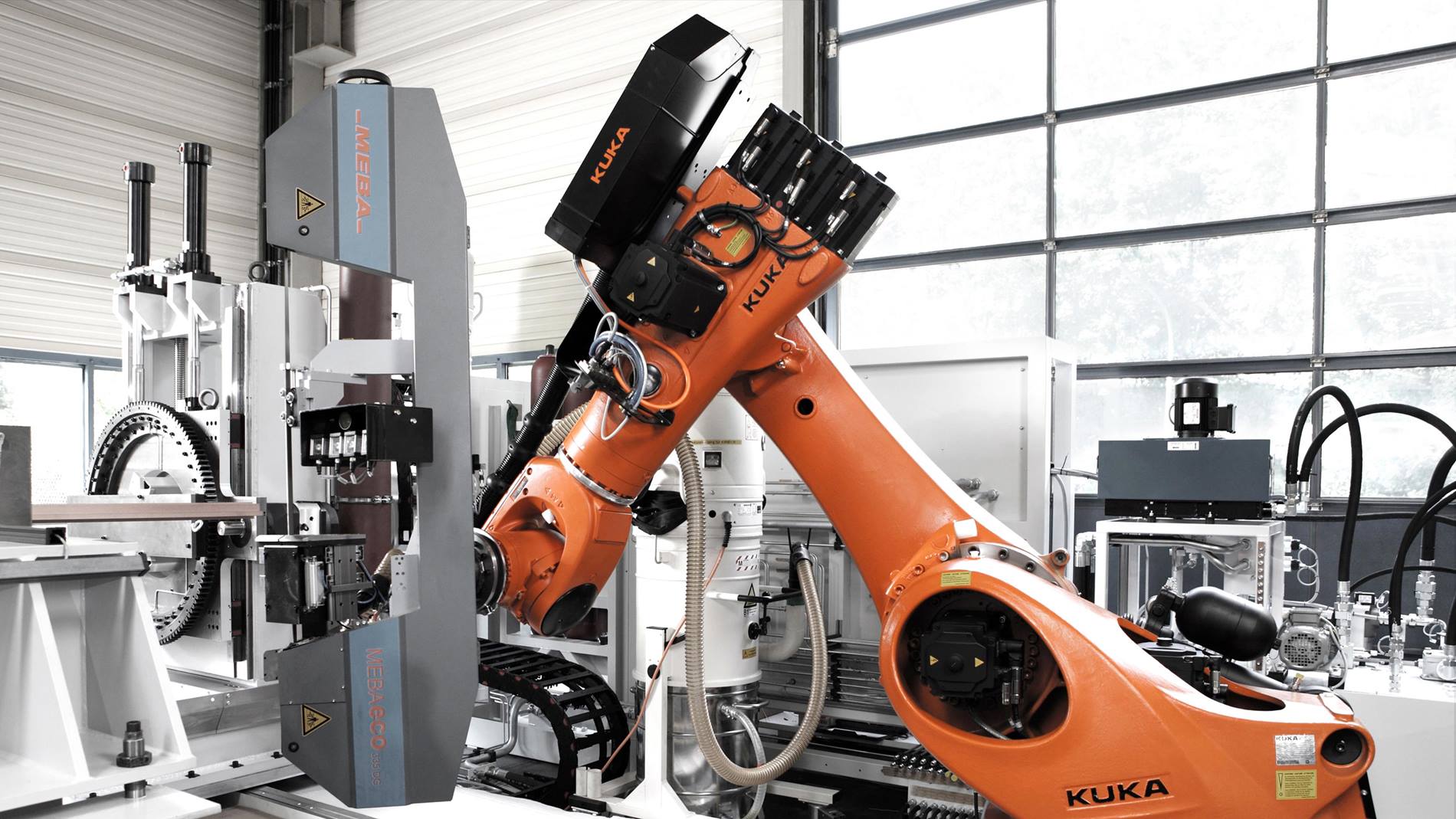

Combination of KR FORTEC and KUKA.VisionTech

Wieland Anlagentechnik opted to use a KUKA heavy-duty robot of the KR FORTEC series with a payload capacity of 360 kg to guide the heavy, deep-throated MEBA band saw (1.35 m center to center distance and outer dimensions of over 2.00 m) and optimally absorb the process forces. This robot stands out for its low-vibration motion characteristics and safe guidance of the saw. The name KR FORTEC, derived from force and forte, stands for strength and dynamics.

Compared to the previous series, the advantages of the KR FORTEC family are clear. The conversion of the in-line wrist from belt to gear technology eliminates the annual belt change, reducing maintenance costs. For the same payload and reach, KUKA was able to increase the axis speeds by up to 18% compared to the previous series. This significantly shortens cycle times.

KUKA.VisionTech is based on the image processing libraries from Cognex, the global market leader in the field of image processing. The application is designed to be easy to use – as is typical for KUKA.

Complete automation of the pointing process

By using a robot and the KUKA image recognition system, Wieland Anlagentechnik has now been able to implement complete automation of the pointing process.

Furthermore, the high repeatability of the workpieces also increases the process reliability of the downstream steps, i.e. the rolling of the pointed cores and subsequent drawing of the pointed cores with a die. Wieland Anlagentechnik presents the new solution at international exhibitions for metalworking.

The modular component range from Wieland Anlagentechnik enables the optimal structuring, precise planning and reliable implementation of complex processes. This also applies to their latest application: the development, on the basis of customer requirements, of a system concept for pointing and then hardening copper profile rods for further processing on drawing benches. The copper rods are pointed by means of a KUKA robot that guides a MEBA band saw.

Solution wanted for varying material thickness and cut direction

„A solution was needed for the complete automation of the pointing process,“ explains Andreas Wiedmann, Head of Development, Marketing and Sales at Wieland Anlagentechnik. „The workpieces cannot be aligned when clamping in the machining position, but only secured in place. This made it necessary to adapt the saw cuts to the spatial position of the workpiece, with both the material thickness and the direction of the saw cuts varying in the course of the process.“ Compared with the previous semi-automated solution, a marked ergonomic improvement for the workforce was also required. “In order to be able to perform the saw cuts freely and independently in space, a solution with a robot was the only option that we considered,” adds Wiedmann.

Image processing system detects workpieces

The six axes of the industrial robot provide maximum flexibility compared with other automation solutions. At the same time, the robot was to have high path accuracy and a stable, low-vibration structure. The demanding requirements on recognition of the copper workpieces necessitated prior tests. These were conducted in the KUKA Roboter GmbH test laboratories. From the first feasibility study through to on-site integration support, image processing experts were on hand to assist the KUKA Engineering department at all times.

The bundle of profile rods is first fed into the system and then separated by the operator with the aid of a manipulator. This is followed by onward transportation to the position of the clamping fixture into which it is fed by means of a roller track. In order to detect the exact position of the copper profiles, Wieland Anlagentechnik uses the KUKA.VisionTech system installed on and guided by the KUKA robot.

The data from the camera system are forwarded to a host computer, interpreted by the software and then output as a 3D sawing curve – a process which, prior to the automated solution, was still carried out manually by means of written markings. The saw cuts are defined on the basis of CAD data and transferred to the KUKA robot. The robot then performs four space-oriented, curved cuts with the band saw. In the next step, the resulting pointed core is oriented in space and rolled to harden the soft copper.

Combination of KR FORTEC and KUKA.VisionTech

Wieland Anlagentechnik opted to use a KUKA heavy-duty robot of the KR FORTEC series with a payload capacity of 360 kg to guide the heavy, deep-throated MEBA band saw (1.35 m center to center distance and outer dimensions of over 2.00 m) and optimally absorb the process forces. This robot stands out for its low-vibration motion characteristics and safe guidance of the saw. The name KR FORTEC, derived from force and forte, stands for strength and dynamics.

Compared to the previous series, the advantages of the KR FORTEC family are clear. The conversion of the in-line wrist from belt to gear technology eliminates the annual belt change, reducing maintenance costs. For the same payload and reach, KUKA was able to increase the axis speeds by up to 18% compared to the previous series. This significantly shortens cycle times.

KUKA.VisionTech is based on the image processing libraries from Cognex, the global market leader in the field of image processing. The application is designed to be easy to use – as is typical for KUKA.

Complete automation of the pointing process

By using a robot and the KUKA image recognition system, Wieland Anlagentechnik has now been able to implement complete automation of the pointing process.

Furthermore, the high repeatability of the workpieces also increases the process reliability of the downstream steps, i.e. the rolling of the pointed cores and subsequent drawing of the pointed cores with a die. Wieland Anlagentechnik presents the new solution at international exhibitions for metalworking.