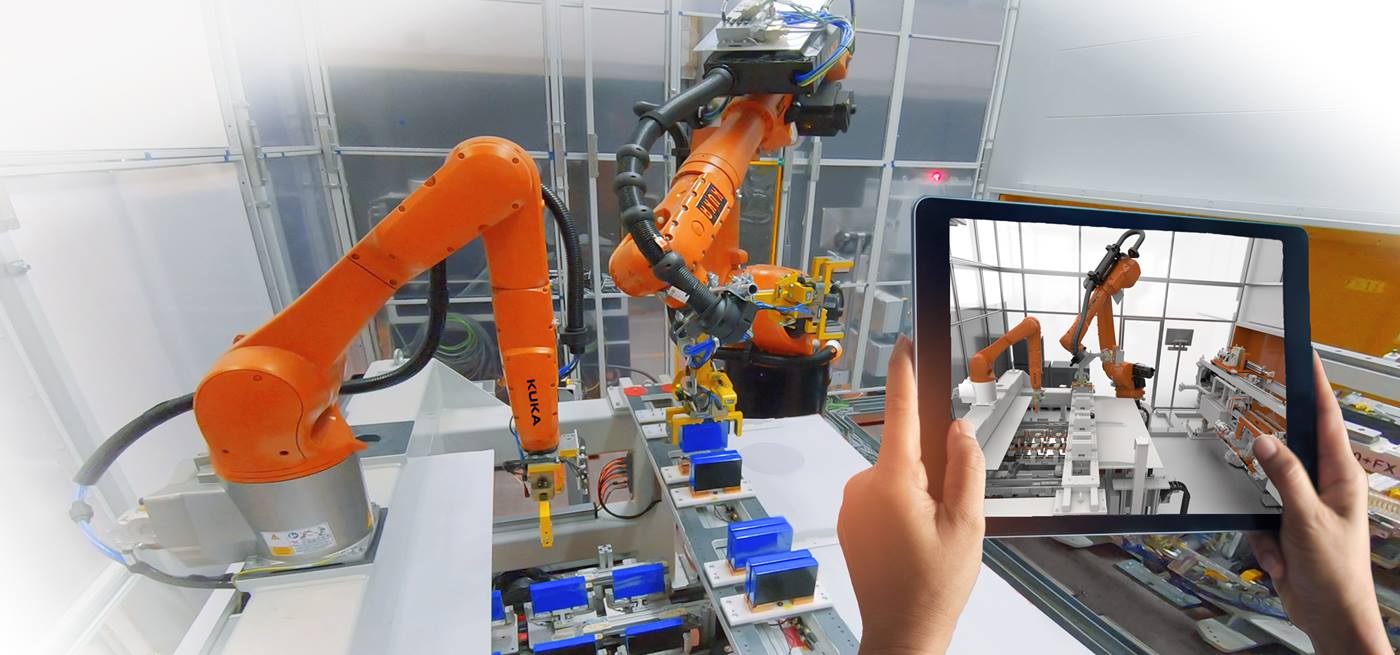

Home game in Munich

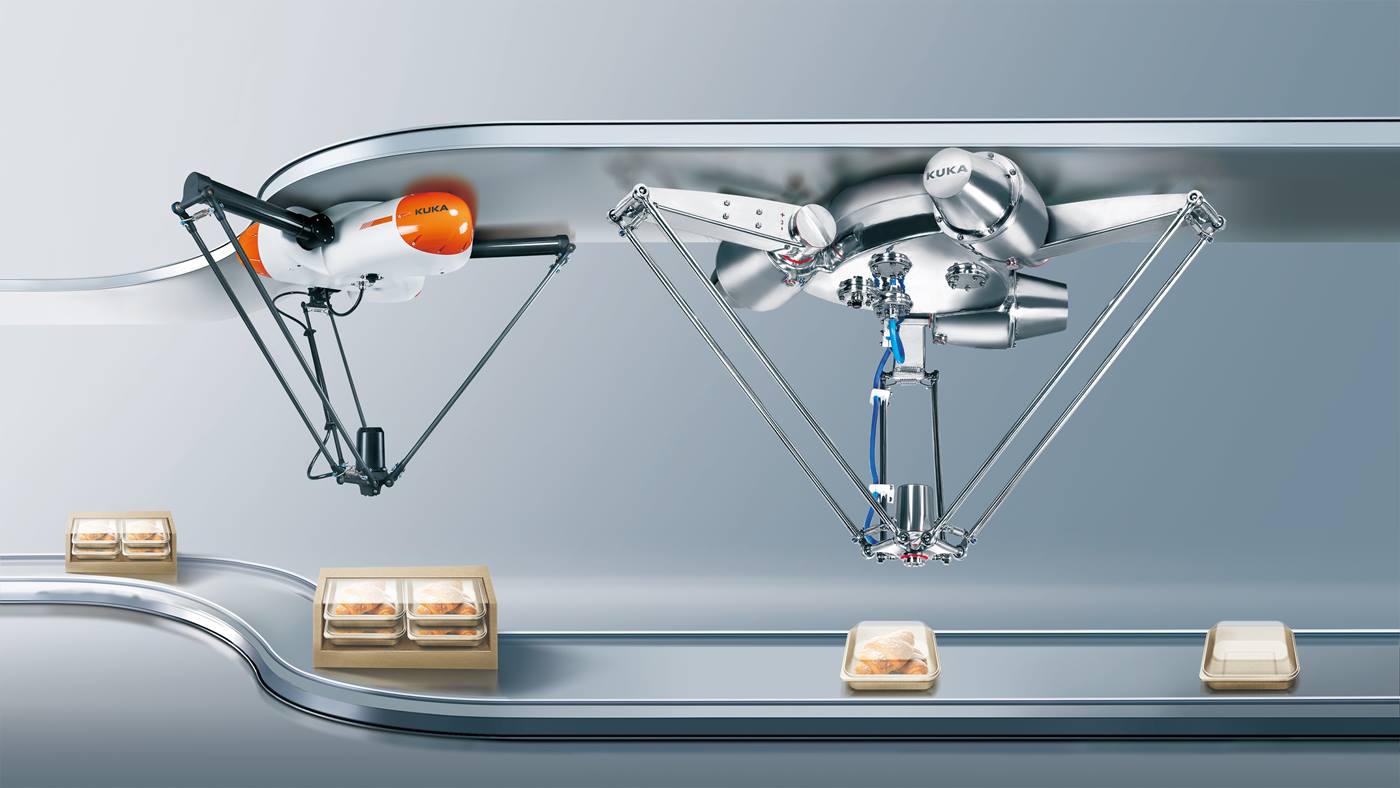

KUKA is once again on site at a major German trade fair. automatica in Munich is traditionally a home game for the Augsburg-based automation group. Here, KUKA is setting off a product firework which shows that KUKA has the right technology for every industry. From June 21 to 24, the focus in Munich will be on "automation for everyone" – from SMEs to food companies, from cleanrooms to microchip production.