Benefit from our Industrial IoT solution

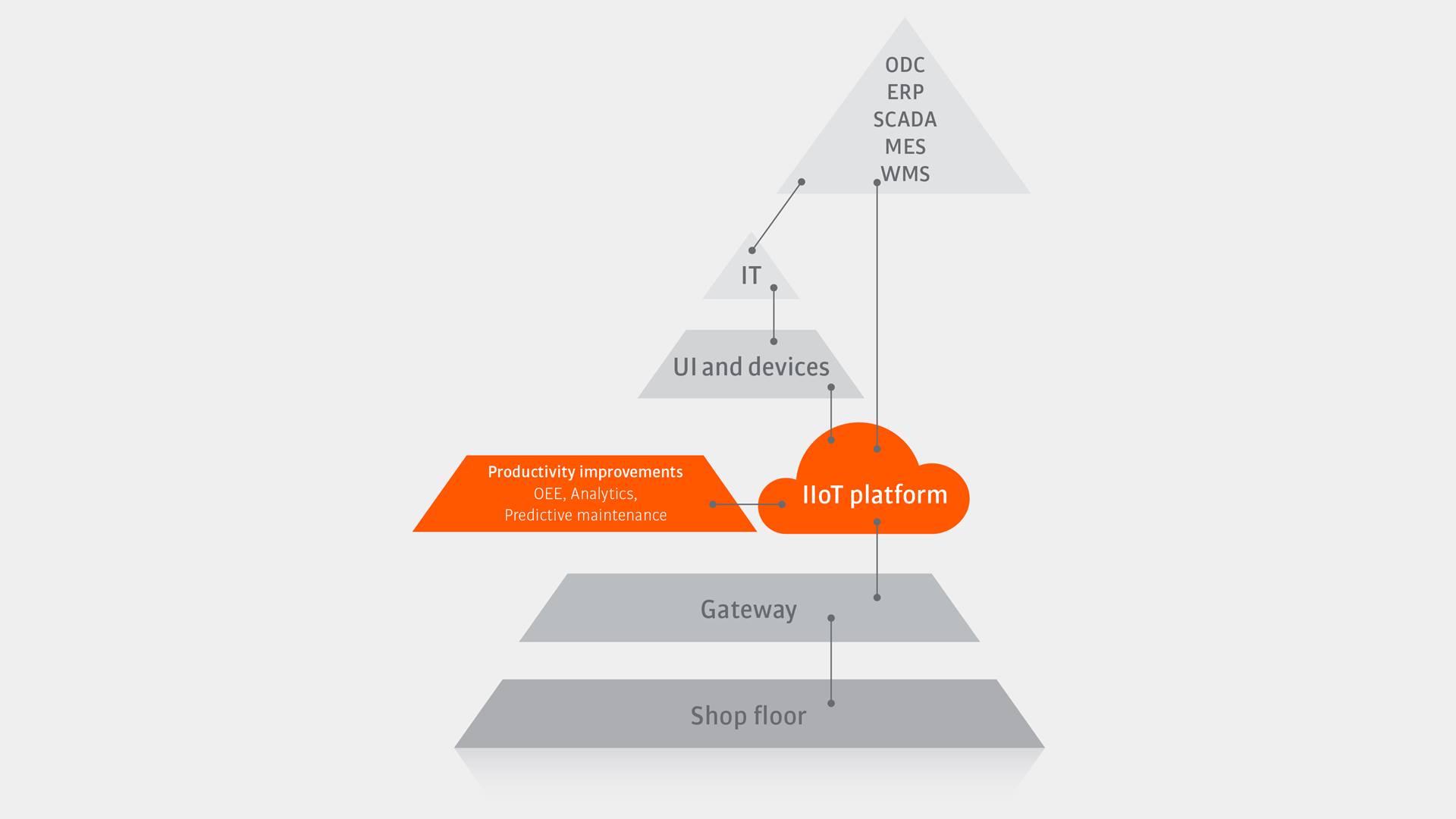

With our Industrial IoT solution, we raise your factory to the next level of productivity and operational excellence.

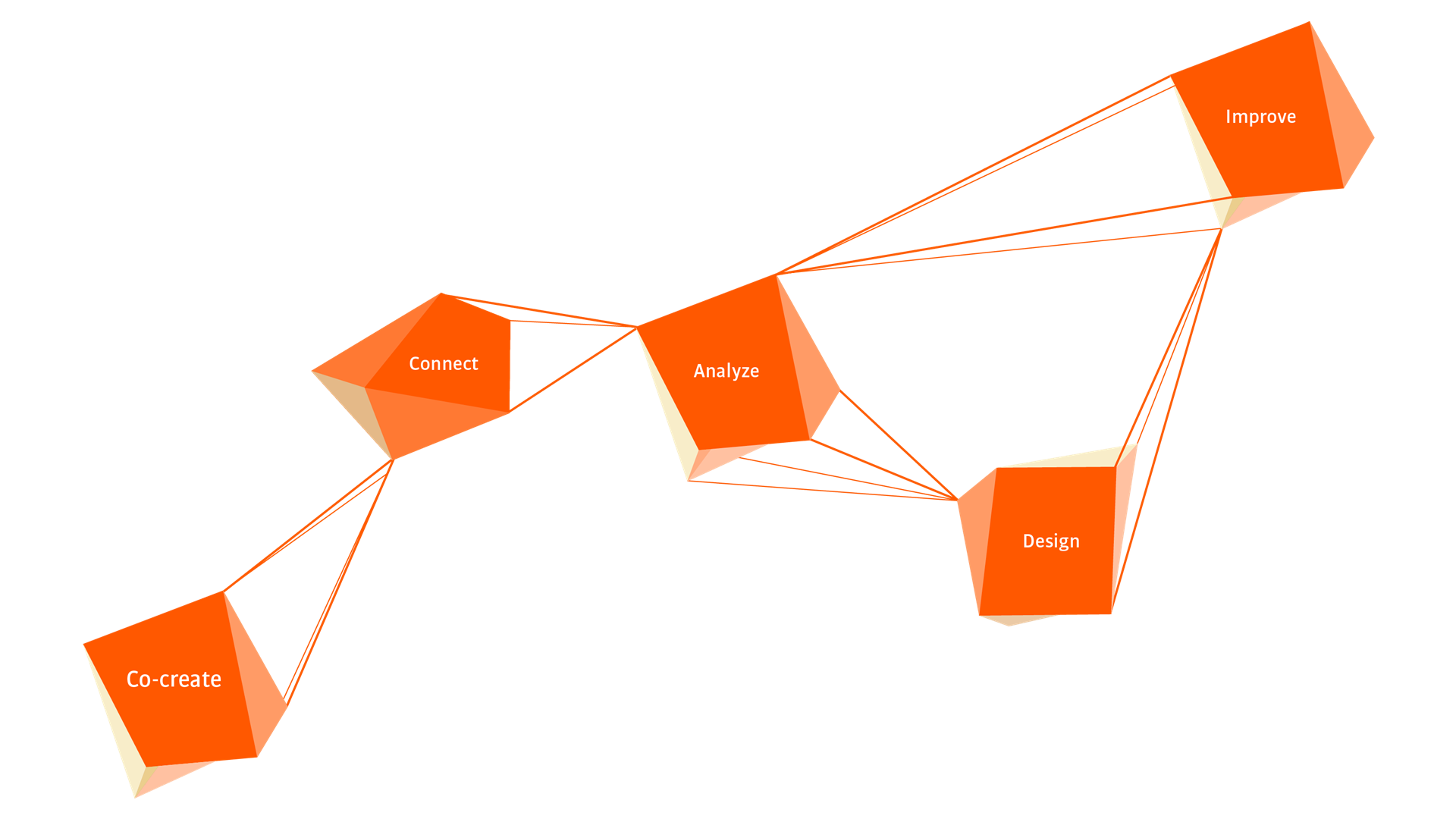

We offer you a tailored end-to-end IIoT solution featuring a modular framework comprised of proven standard components. These can then be customized and applied to meet your specific requirements. Powered by online analysis of shop-floor data, we quickly deliver significant operational impact.