Robot prepares fast food dishes

It is now impossible to imagine mass production without robots. Smartphones are now almost universally assembled by robots. There are now 45,000 robots working in Amazon’s American warehouses. They pick orders and load delivered goods onto the high shelves. General Motors already has 8,000 robots in operation, which are even controlled via a cloud. But if you now think that small companies have far too much trouble introducing robots, you are mistaken. The Brazilian company Bionicook, for example, installed what is probably the world’s first fast-food robot machine: a KR 3 AGILUS cooks and serves guests snacks, drinks, and desserts.

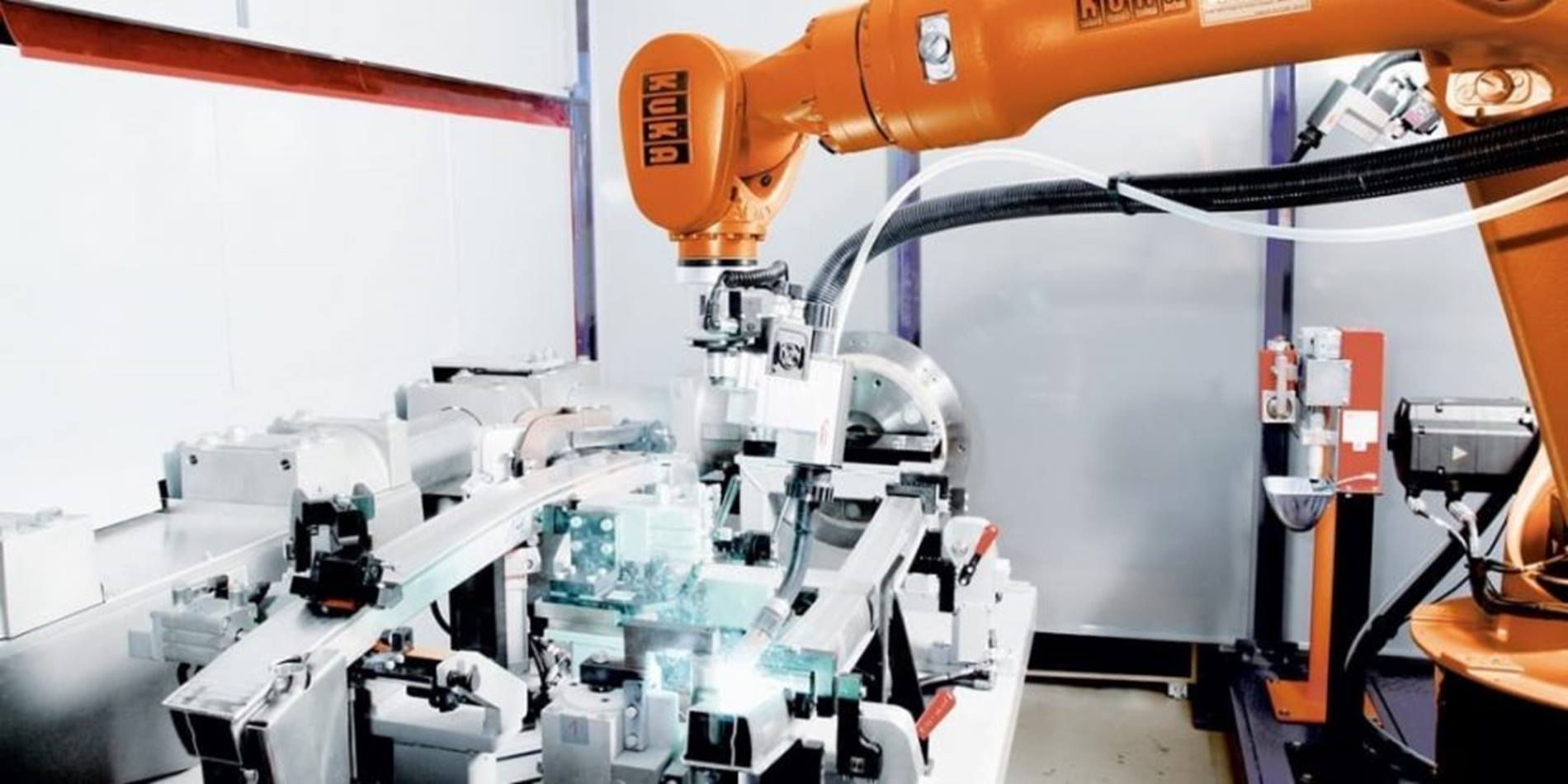

Robot loads bending machine with 100-kilogram trays

The pizzeria may be a somewhat bizarre start-up from Silicon Valley. But more and more medium-sized German companies in the manufacturing industry are also using robots. Walter Wurster GmbH from Leinfelden-Echterdingen, for example, installed a KUKA robot to load and unload a bending machine. The company, with 50 employees, produces, among other things, the casing of bakery ovens made of stainless steel sheets. The workpieces weigh up to 100 kilograms. The KUKA robot assists with the four-stage bending process by relocating the workpieces. The bending machine runs almost completely autonomously and performs the work that was previously done by three employees.

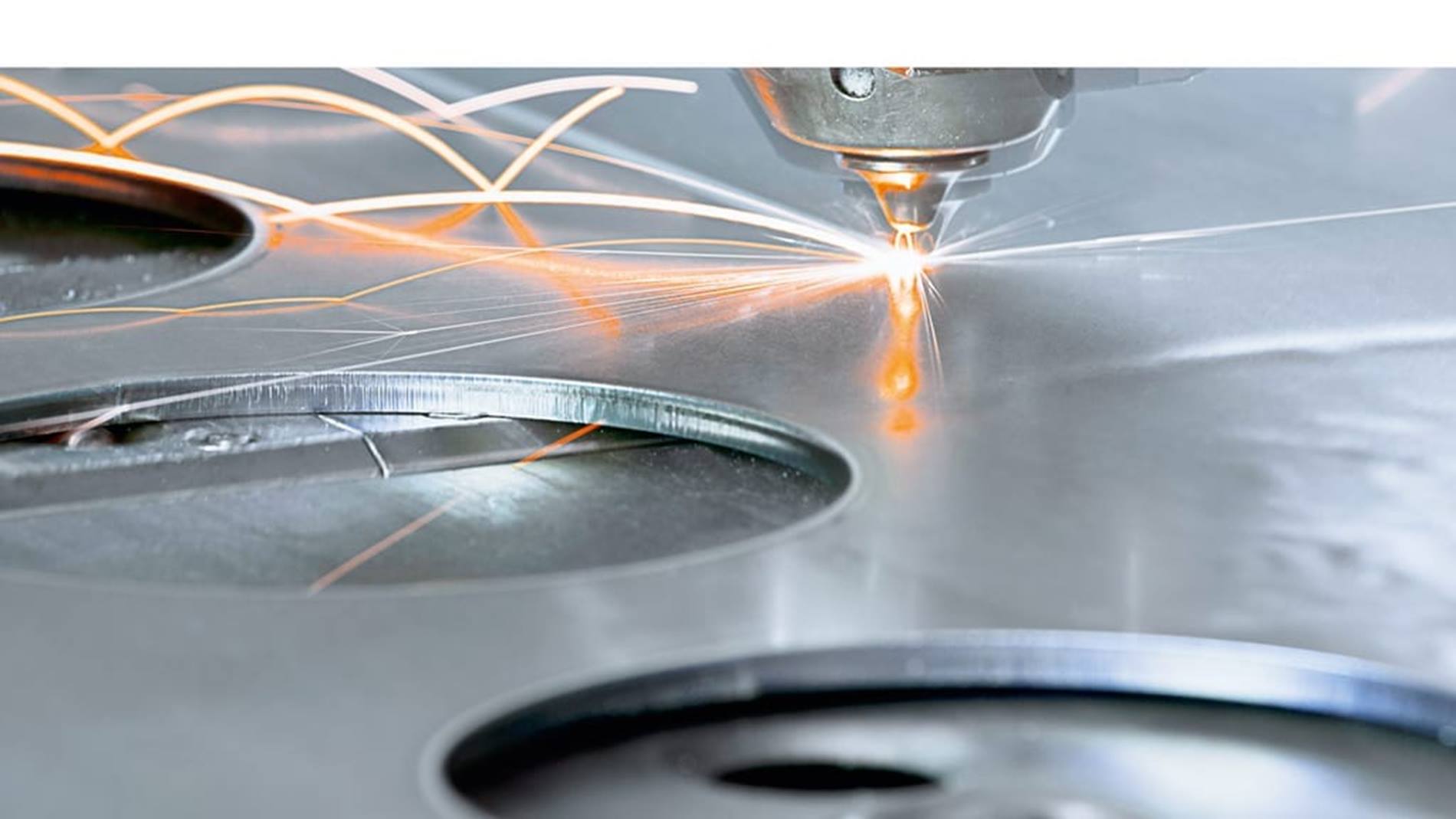

Robots make production worthwhile again in Germany

In general, the use of robots is suitable for sheet metal processing, especially for workpiece handling. On behalf of a Thuringian company specializing in ventilation pipes, SHL Automatisierungstechnik AG from Böttingen implemented a robotic system solution. KUKA robots load, unload and assist in the welding process. A robot takes two to three workpieces of a pipe bend from the pallet and guides them into a welding station for circumferential seam welding. It then transfers to a belt grinder for grinding the seam on the outer radius. Another robot then feeds the workpiece to another belt grinder for grinding the inner radius. If necessary, it also transfers to a polishing machine. At the end of the process, it places the finished part in a workpiece pallet. It was only with this solution that the sheet metal processor was able to bring production, which had previously been relocated to Eastern Europe, back to Thuringia.

There are tasks for robots in every manufacturing operation

These examples show that the use of robots today pays off, especially for smaller manufacturing companies. This is because they have become less expensive to purchase and maintain. By taking over strenuous work with heavy workpieces, they relieve the employees. They can devote themselves to more skilled work. All in all, productivity increases and unit labor costs fall.