KUKA.SeamTech Tracking and KUKA.SeamTech Finding

The KUKA.SeamTech Tracking and KUKA.SeamTech Finding application software can be optionally added to the KR C4 robot controller. With the aid of an intelligent triangulation sensor, the robot can use KUKA.SeamTech Finding to detect components and seams prior to welding and use KUKA.SeamTech Tracking to track edges and seams during the welding process.

Advantages of KUKA.SeamTech

Smooth communication between sensor and controller

KUKA.SeamTech Finding and Tracking are options for controlling and programming intelligent triangulation sensors via Ethernet – SeamTech Tracking even makes use of a powerful real-time protocol.

Programming made easy with KUKA programming aids

The application programming of robot sensor commands is carried out as usual with clear inline forms that can be programmed quickly. Status keys which enable robot and sensor functions to be operated quickly also support this process.

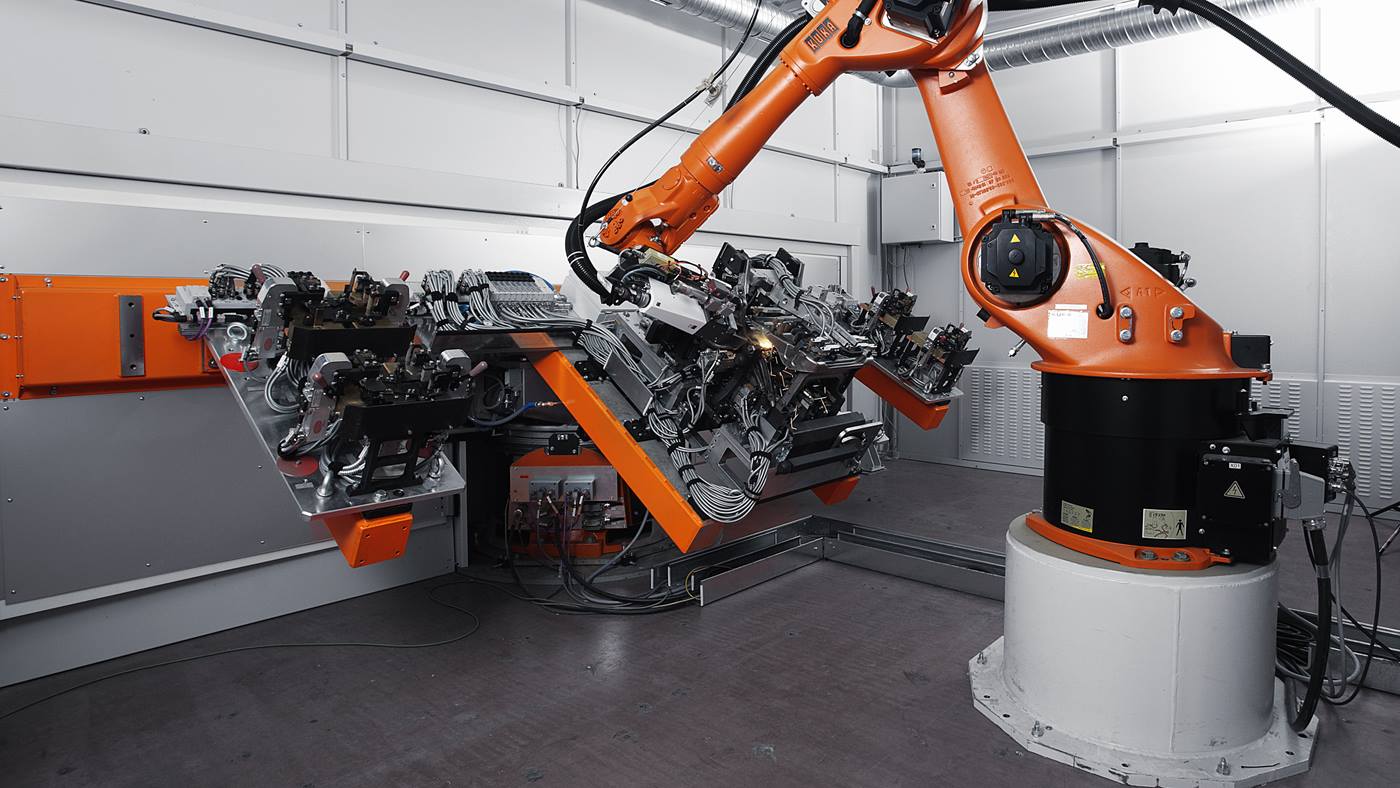

Flexibly combinable technology packages

KUKA.SeamTech Finding and Tracking are independent technology packages that can be combined with other options, for example with ArcTech Basic, ArcTech Advanced, LaserTech or GlueTech.

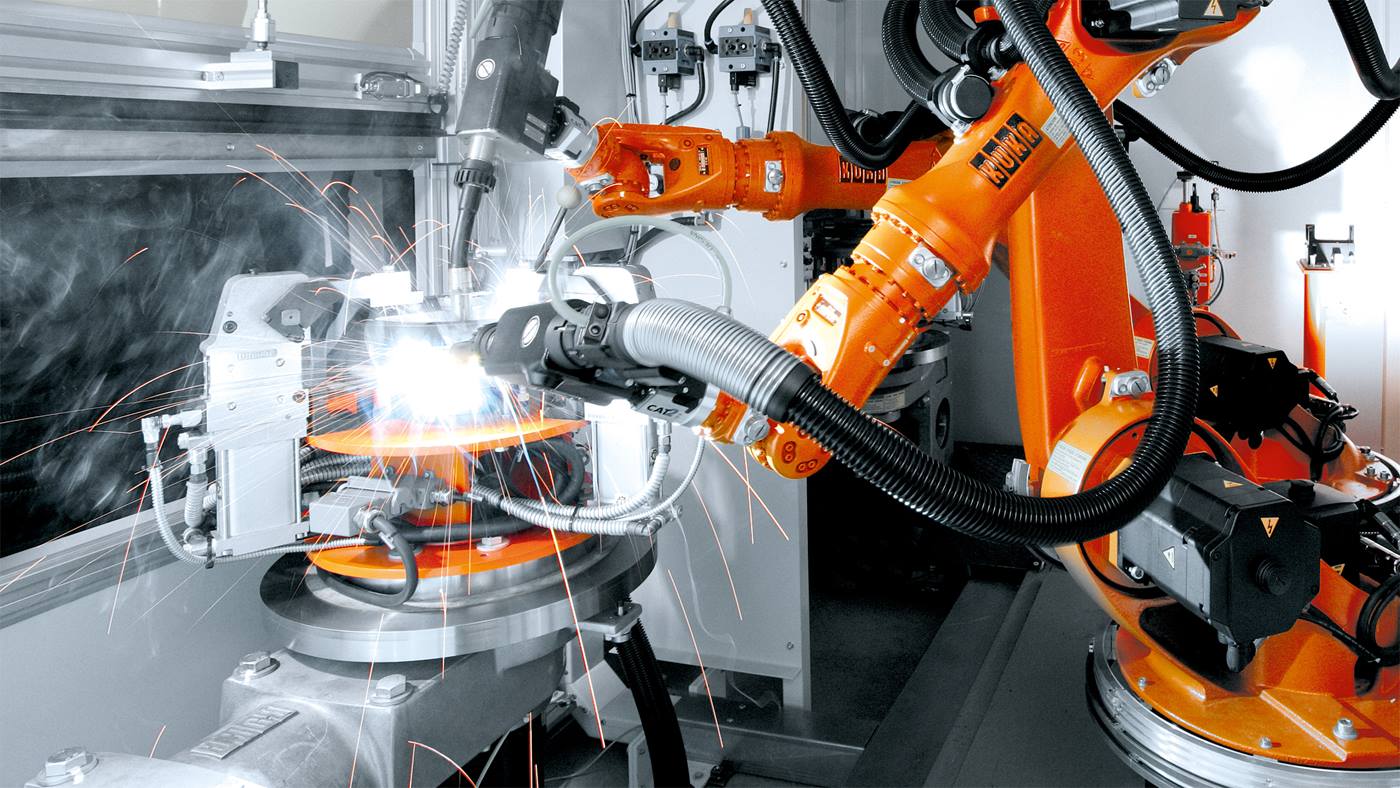

KUKA.SeamTech Tracking

KUKA.SeamTech Tracking can be used to perform edge and seam tracking using a sensor from the manufacturers SERVO-ROBOT Inc, Scansonic MI GmbH, BavariQ Sensor GmbH & Co. KG or wenglor sensoric GmbH. Sensor systems from other companies that communicate via Ethernet and XML protocol can also be connected. These can be added to WorkVisual by the user with an interface protocol adapted to the sensor. Thanks to KUKA’s particularly powerful Ethernet real-time interface, the sensor system can carry out high-precision robot path correction with ease not only at the typical MIG/MAG and TIG welding speeds but also at the very high speeds used in laser welding.

The seam tracking process can be programmed to suit each individual welding application using the independent inline forms, for example, on the fly or with exact positioning. Furthermore, SeamTech Tracking also provides special commands for searching for seam start and end positions dynamically. This allows the robot to independently adapt the seam position and length according to the component being welded.

KUKA.SeamTech Finding

KUKA.SeamTech Finding can be used to operate sensors from the manufacturers SERVO-ROBOT Inc, Scansonic MI GmbH, BavariQ Sensor GmbH & Co. KG or wenglor sensoric GmbH. Sensor systems from other companies that communicate via Ethernet and XML protocol can also be connected. These can be added to WorkVisual by the user with an interface protocol adapted according to the sensor. The great advantage of component and seam detection using intelligent line laser sensors is that they can capture multiple component geometry data in a single measurement.

The KUKA.SeamTech Finding software uses the captured component geometry to calculate a linear and/or rotational offset of the component, seam, or individual path points at great speed. The programmer can use these calculations to activate and deactivate corrections in an extremely flexible manner in up to six dimensions. In this way, the component can be processed with extremely high accuracy and process reliability.