How does laser metal deposition work?

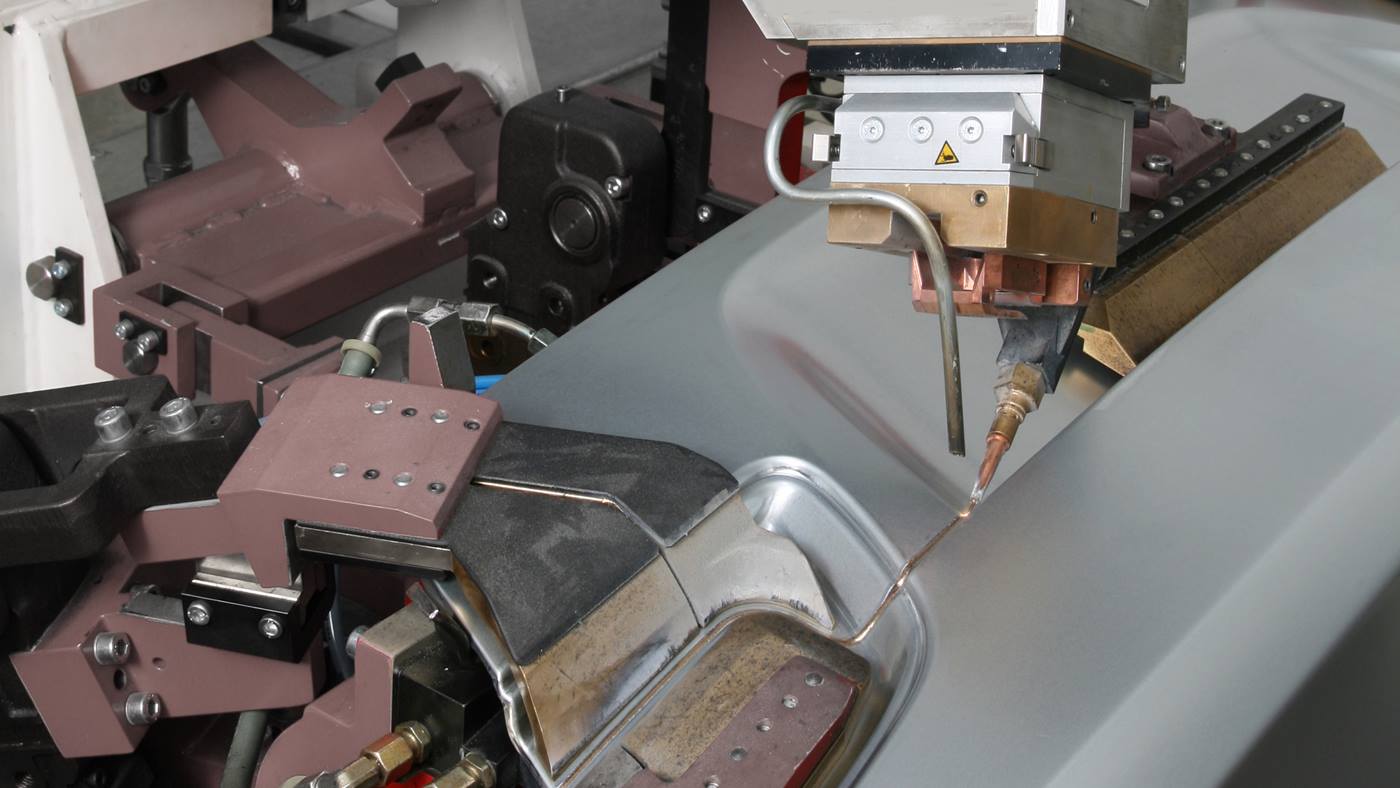

A high-power laser is used as the heat source in laser metal deposition. During this process, a surface layer is created by means of melting and simultaneous application of virtually any given material. The filler material can be supplied either in powder form e.g. as metal powder, or with a welding wire. When laser metal deposition is carried out using powder, the laser usually heats the workpiece with a defocused laser beam and melts it locally. At the same time, an inert gas mixed with a fine metal powder is introduced. The metal powder melts at the heated area and is fused to the surface of the workpiece.

Deposition welding using lasers: the advantages of the process

- Don't replace it, repair it: Even minor damage or normal wear and tear on complex or expensive components tends to result in significant outlay - the affected parts often need to be completely replaced. This makes repairs worthwhile. Laser metal deposition is the ideal process for cases such as these.

- Functionalized surfaces: A broad spectrum of materials can be used during the laser metal deposition process to optimize the surface for the required function, e.g. for wear and corrosion protection.

- The generative manufacture of components or functional elements is used in the field of industrial manufacture on an increasingly regular basis. When it comes to large components such as turbine elements, adding functional elements by way of laser powder deposition can lower production costs significantly. No additional tools are required for the process, making it straightforward to carry out.

- Low level of heat application at the welding area: The levels of distortion remain within narrow tolerances and, in many applications, the weld structure of the applied material either meets or exceeds the requirements placed on the original parts. As such, deposition welding by laser allows for a low level of heat application and ensures a high level of quality.

Automated laser metal deposition

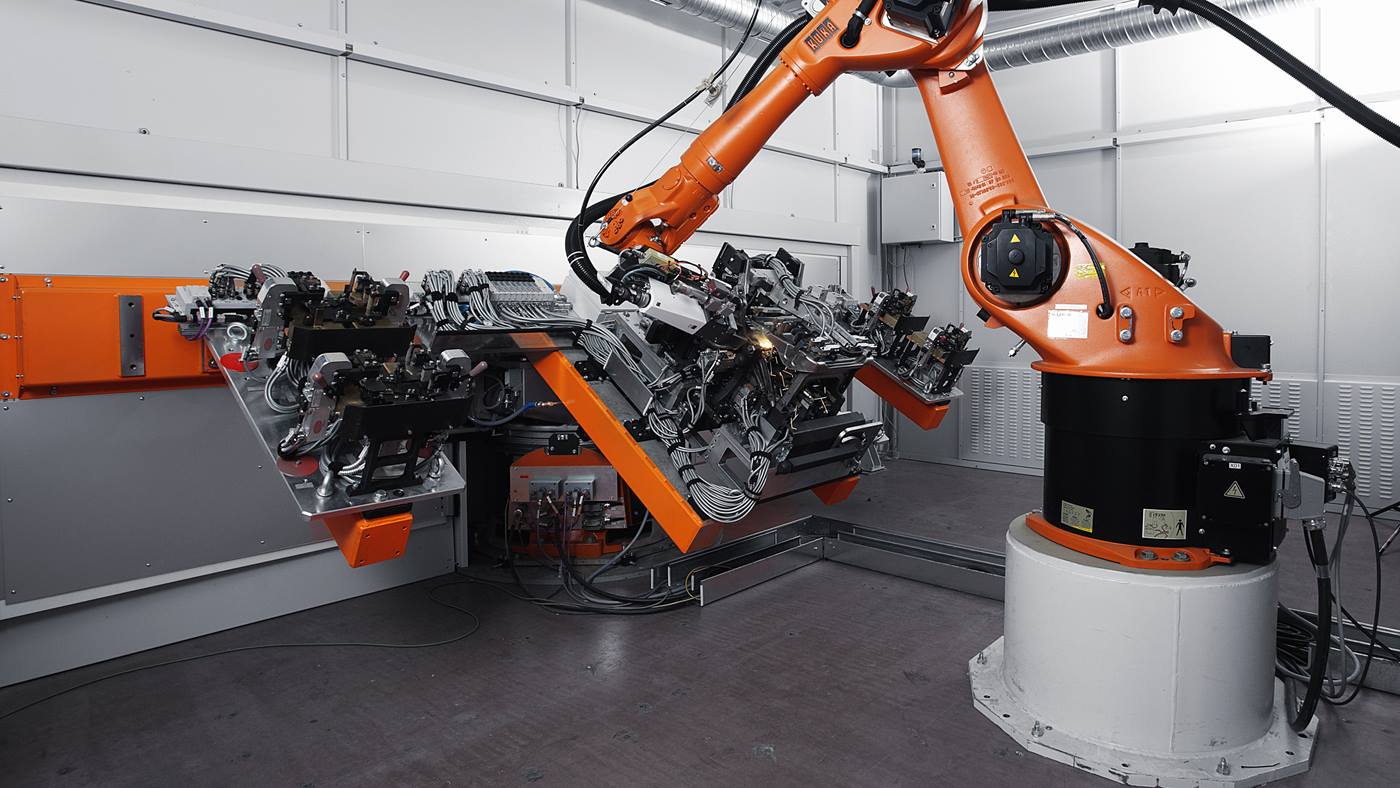

KUKA provides customized solutions and all types of production technology for laser metal deposition – this ranges from modular robotic cells to fully-automated systems – also in conjunction with other joining technologies.

Laser metal deposition: hybrid additive manufacturing

Discover the hybrid additive manufacturing solution from KUKA. The goal of the ProLMD project is the industrial implementation of hybrid manufacturing processes using laser technology. A Quantec KR 90 HA robot builds up new structures layer by layer on a conventionally manufactured base component. Thanks to the use of a fiber-guided system, the robot remains virtually unrestricted in its workspace. This makes it possible to respond flexibly to component geometry and size – even in the case of small batch sizes. The development of a locally integrated shielding gas system, which is only deployed when required, offers further advantages. This system is supplemented with new laser processing heads, which make use of both wire and powder as filler materials, as well as with a computer-aided manufacturing (CAM) system suitable for hybrid production. Several filler materials are being researched within the framework of ProLMD with a view to developing highly efficient laser material deposition processes.