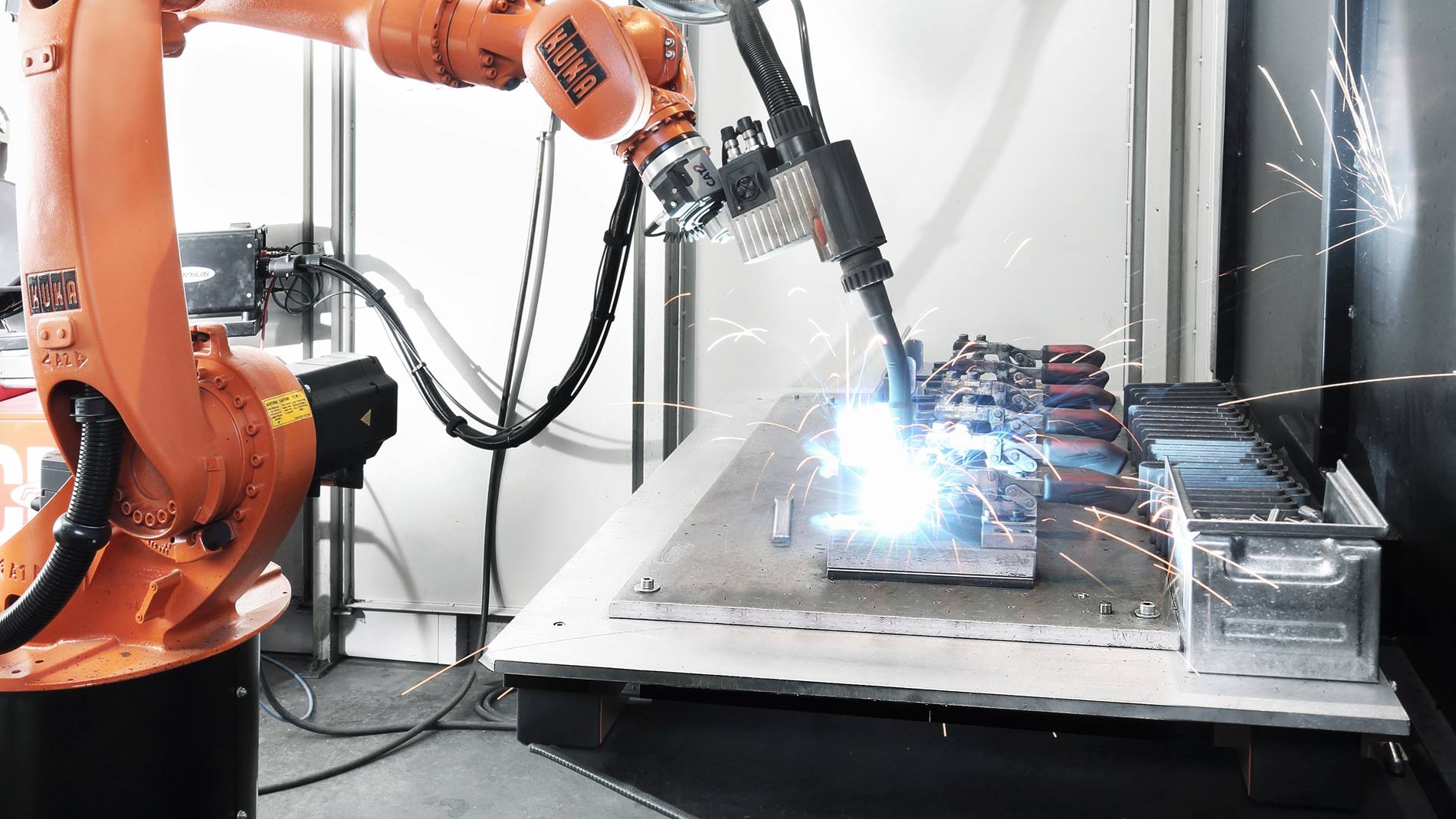

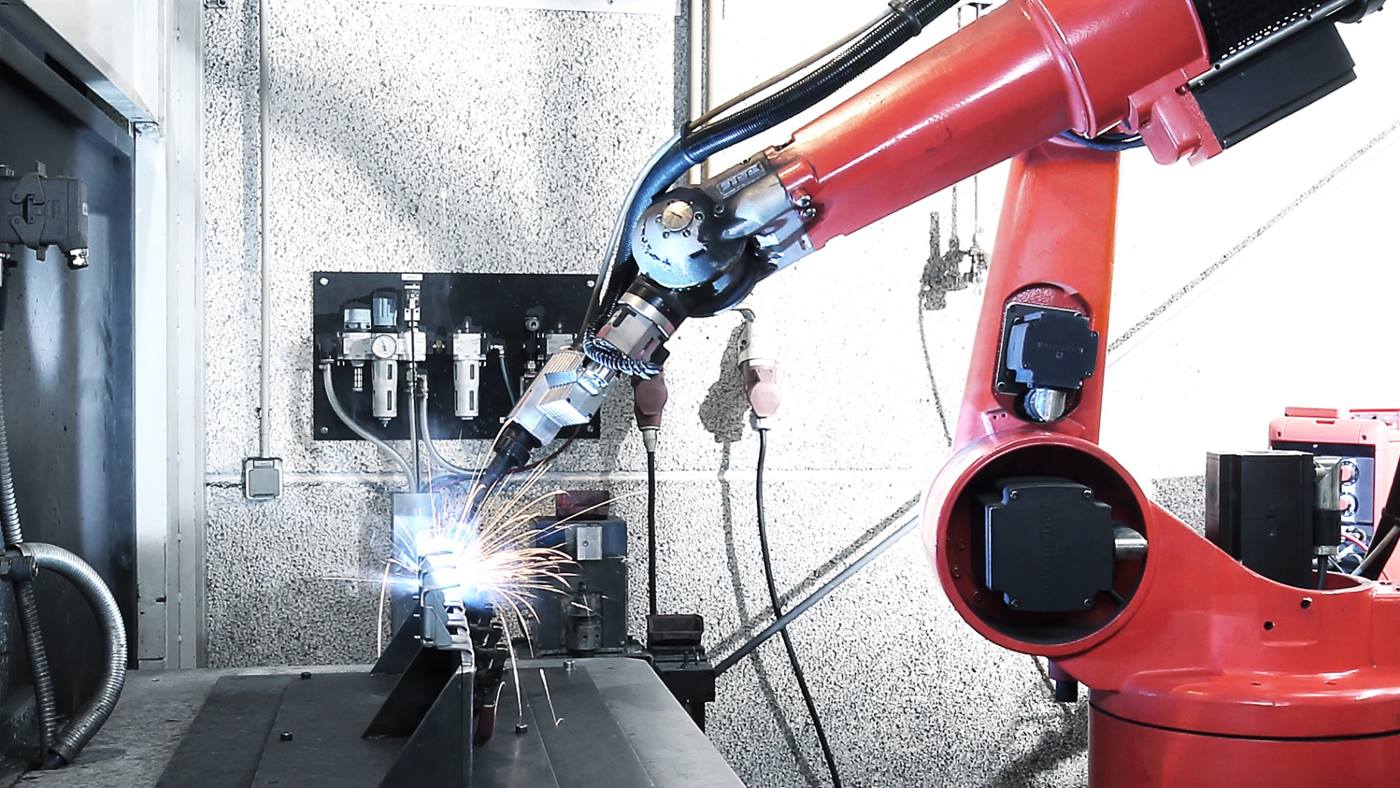

Arc welding cell in the Lebenshilfe workshops

The workshops at Lebenshilfe Limburg GmbH rely on technologically sophisticated equipment developed by KUKA Industries

The task

The automation specialists from Obernburg am Main won the managers over with their systems. Meanwhile, four industrial robots are in operation at Lebenshilfe Limburg gGmbH – the most recent one bearing the KUKA brand. One of the customers with whom Lebenshilfe has a production contract will purchase an additional KUKA model for the workshops. Not many of the Lebenshilfe workshops have such high-tech equipment. Ultimately, it is difficult to compare their work to that taking place in other industrial enterprises: here, the orienting principles of social responsibility and employing people with an intellectual disability take precedence over economic concerns. Simple and flexible handling is required since the robot cells are operated by people with a wide variety of abilities. This is why it is important for the system to adapt to the rhythm of the human operator. And not the other way round.

The solution

For contract work, KUKA Industries designed a compact welding module based on a six-axis industrial robot with jointed-arm kinematics as well as an innovative portable programming tablet. The programmer now just works via a user interface, without mechanical and electrical operator control elements. “The new jointed-arm robot is more compact and agile than its predecessor. A welding source with external wire feed is flange-mounted on the robot wrist.

At its operating site in the Lebenshilfe workshops, the welding module is used for gas-shielded arc welding. The special feature of this process: the liquid metal at the welding point is protected against oxidation through the introduction of certain gases.

The requirements that these cells must meet are:

- the highest degree of flexibility

- in the smallest of installation spaces

- most straightforward programming procedure

- in conjunction with innovative apps

We wanted to keep up with technology. It is important to us as the user that the interfaces are suitable and that operation is comparable.