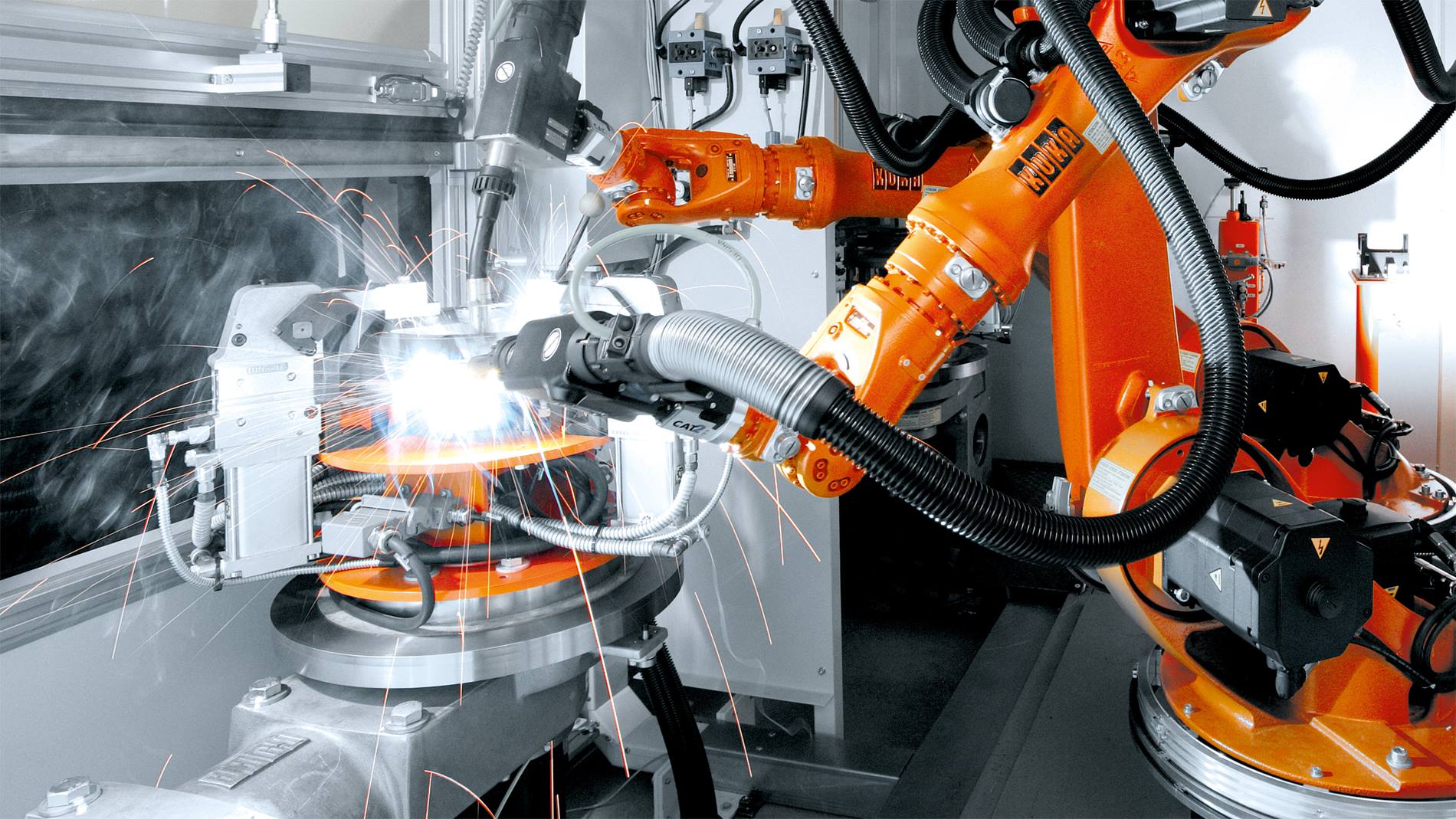

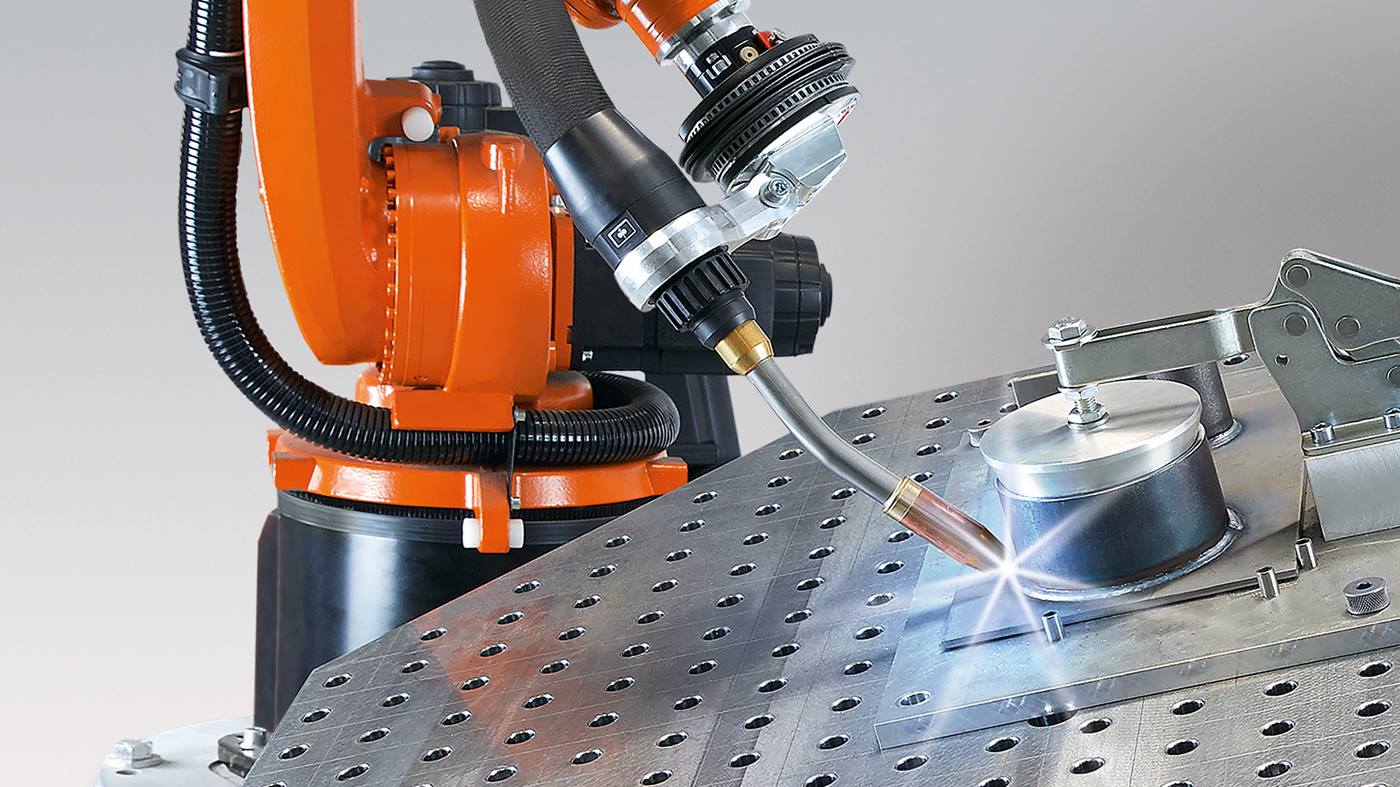

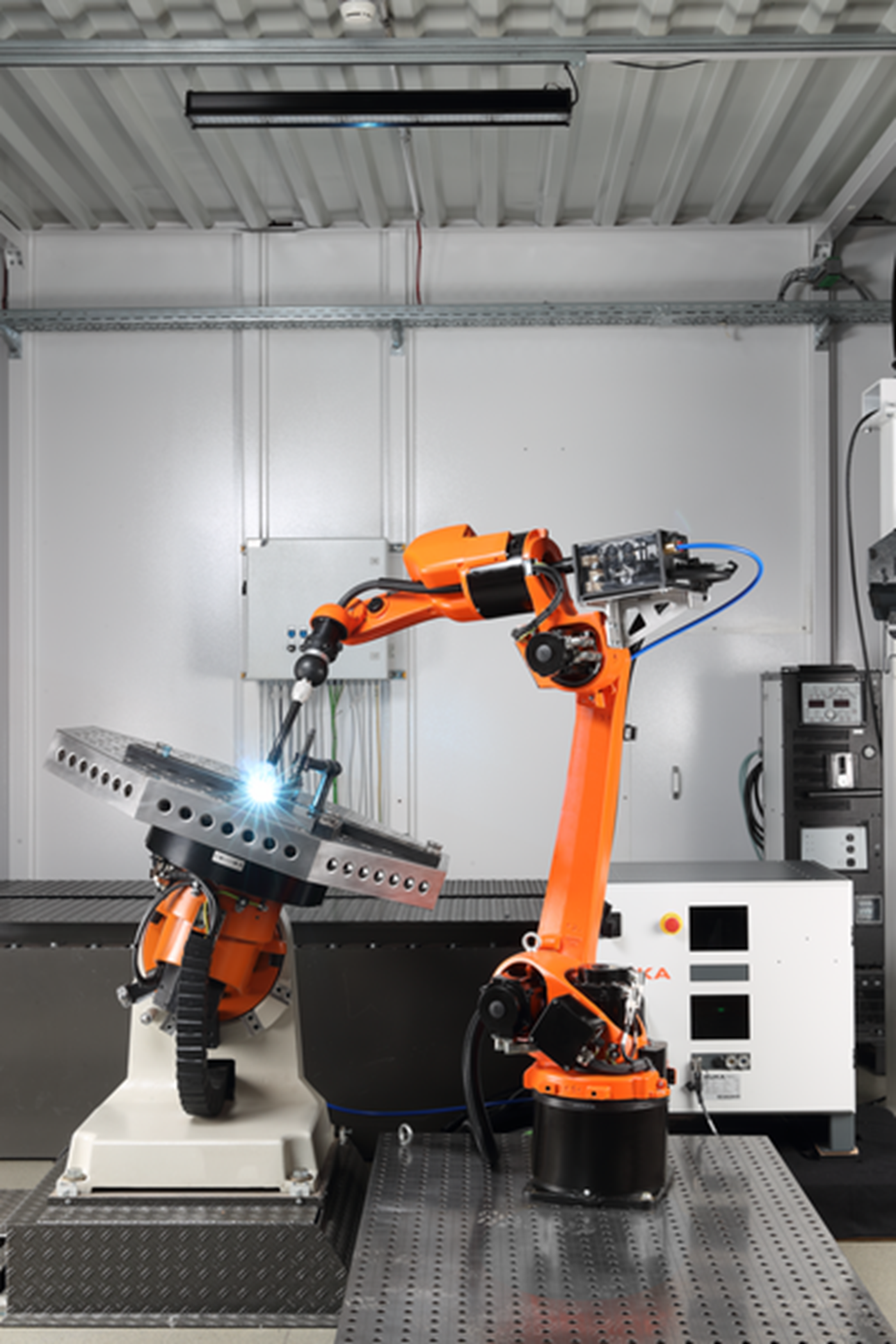

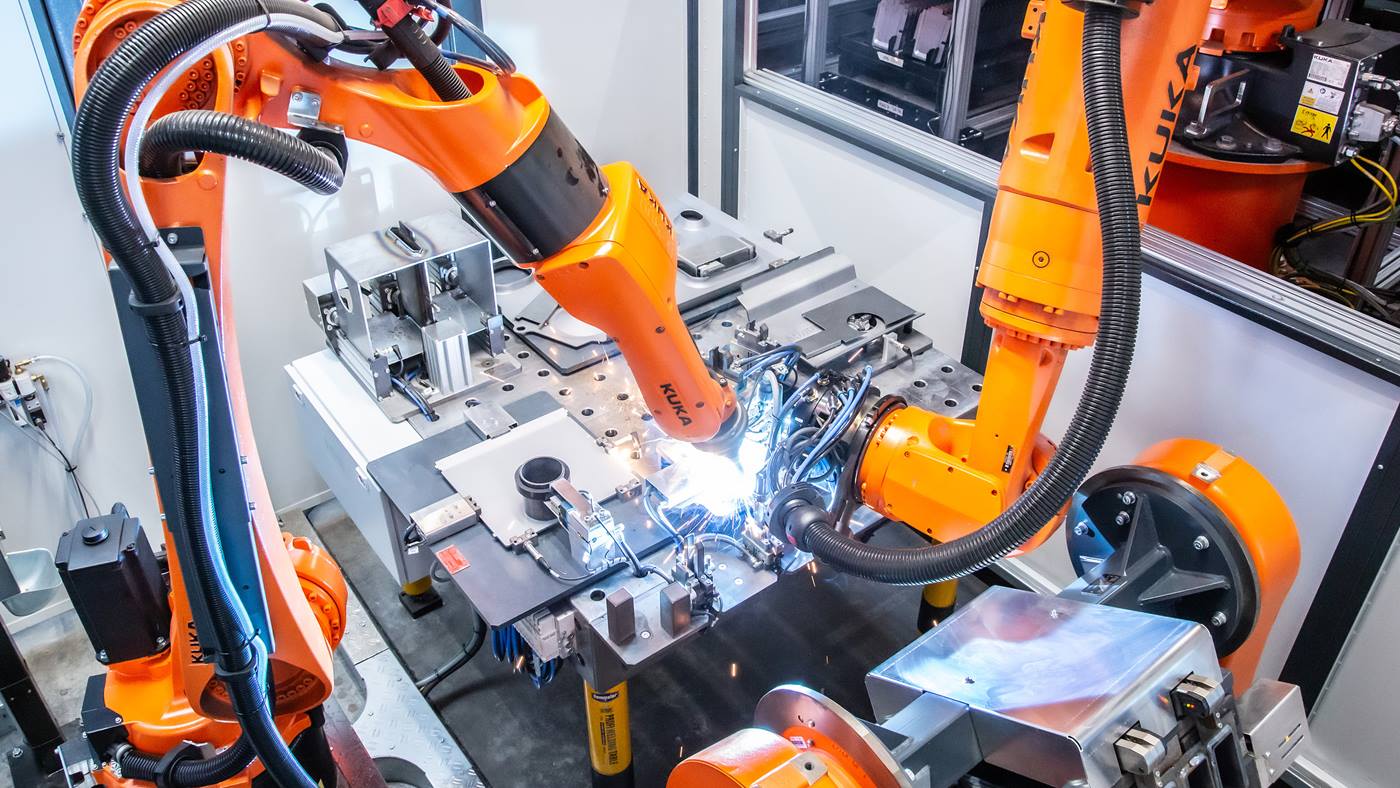

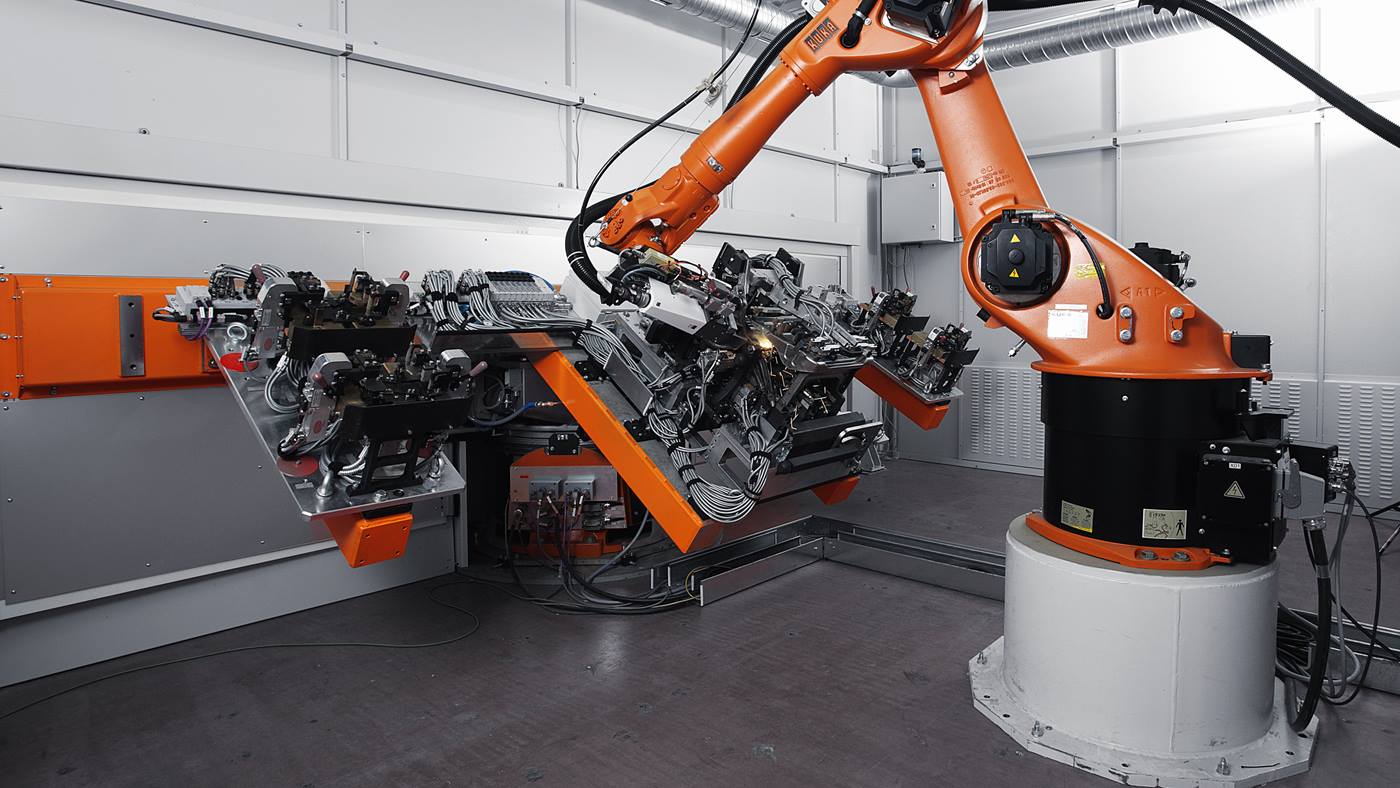

Robotic arc welding with KUKA robots: always one step ahead

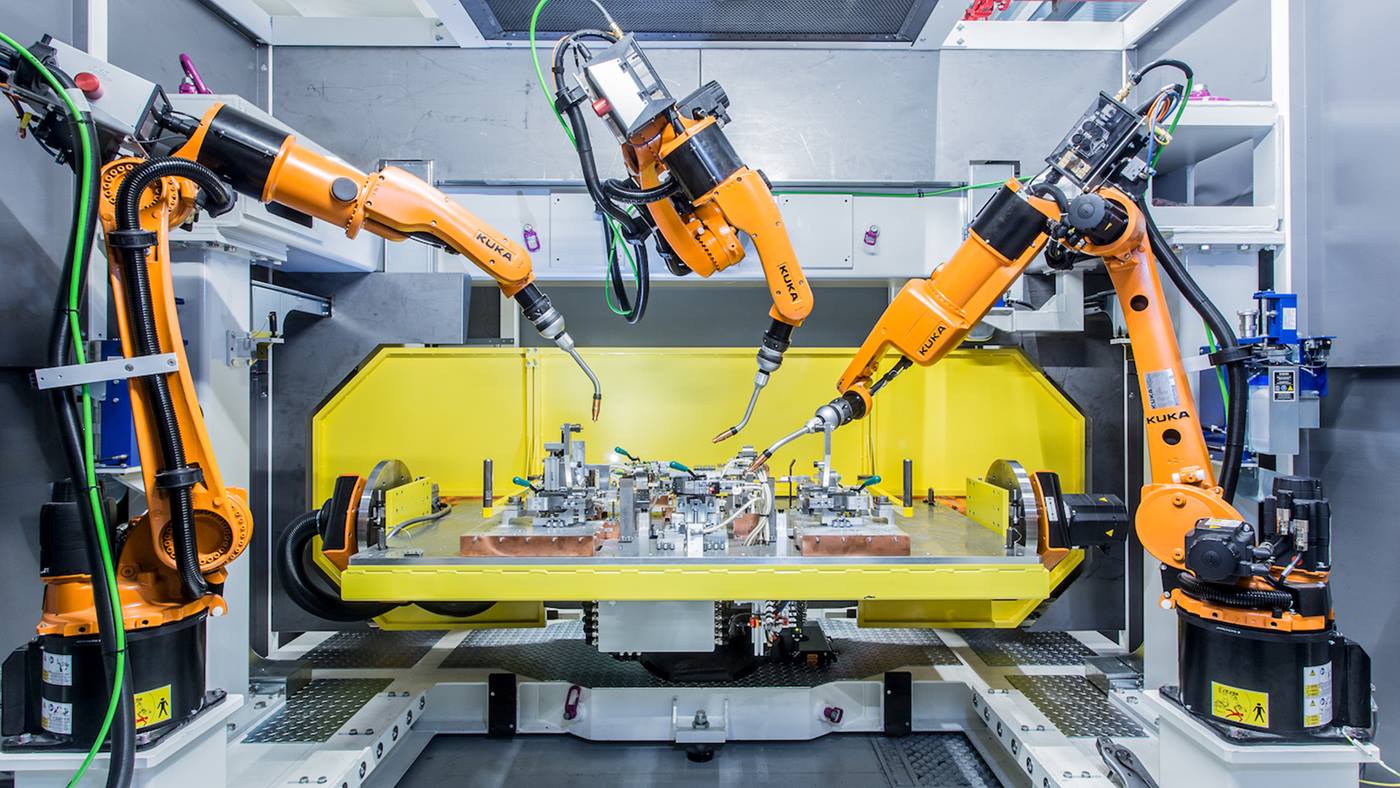

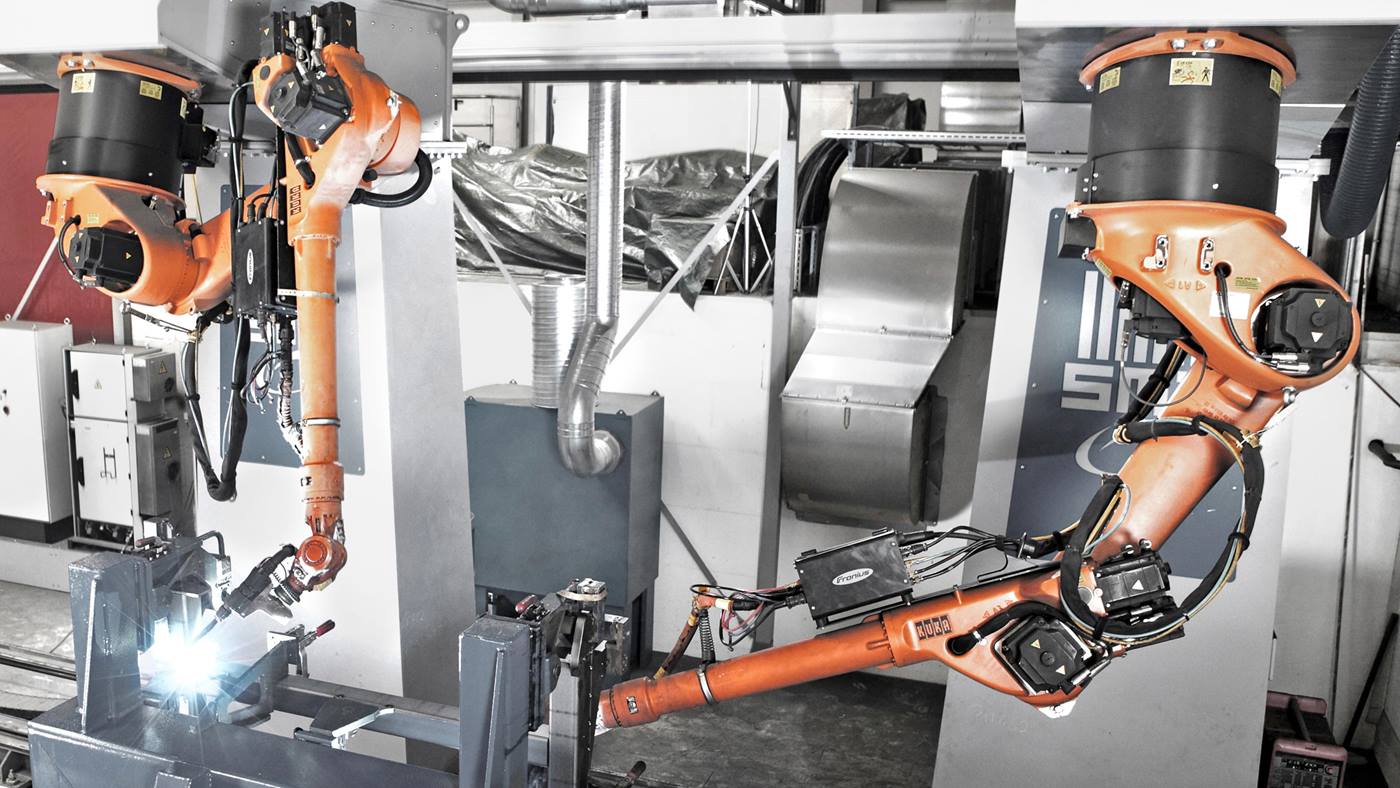

Robotic arc welding is a highly effective method used in various industrial environments. It is fast and can work with many types of metal. At KUKA, we provide more than just regular welding functions. We excel in robotic welding systems and automated welding processes, enhancing efficiency in manufacturing.

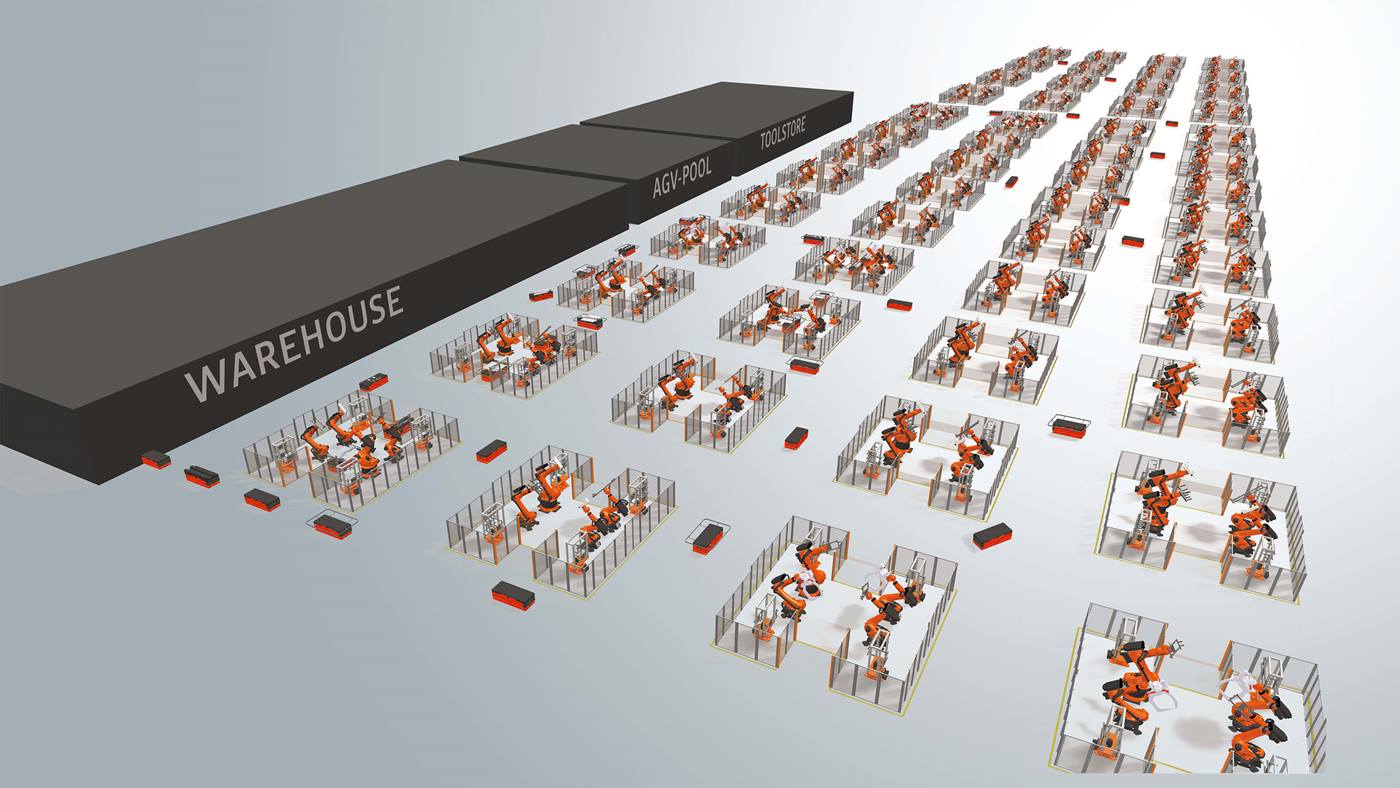

Our smart integration capabilities connect you to the digital and networked world of production. Our solutions transform manufacturing with industrial robots that integrate advanced technology. The result is more effectiveness and flexibility with KUKA machines. This applies to the whole value chain in robotic welding. Our units ensure consistent quality in welding applications by performing complex, repetitive tasks.