Matrix production live at KUKA SmartProduction Center

Experience today the production of tomorrow at the KUKA site in Augsburg. In the KUKA SmartProduction Center, the versatile and flexible matrix solution becomes reality. Different products can be manufactured on the same system – customized production is possible.

21 February 2018

Our intelligent software has an overview. It knows where the moving AGVs are located, which component the AGV needs to deliver to the robot, and quickly prepares a conversion.

A smart solution is needed.

Increasing type variety, more frequent changes of model, quantity fluctuations: the new market conditions require a suitable and competitive production solution. “We can offer this with matrix production,” says Harald Heinrich, Head of Competence Center of the KUKA Automotive division.

How can I produce different parts on a single system? How can production be stepped up at short notice? How can I carry out a change of type within a short period of time on the same system?

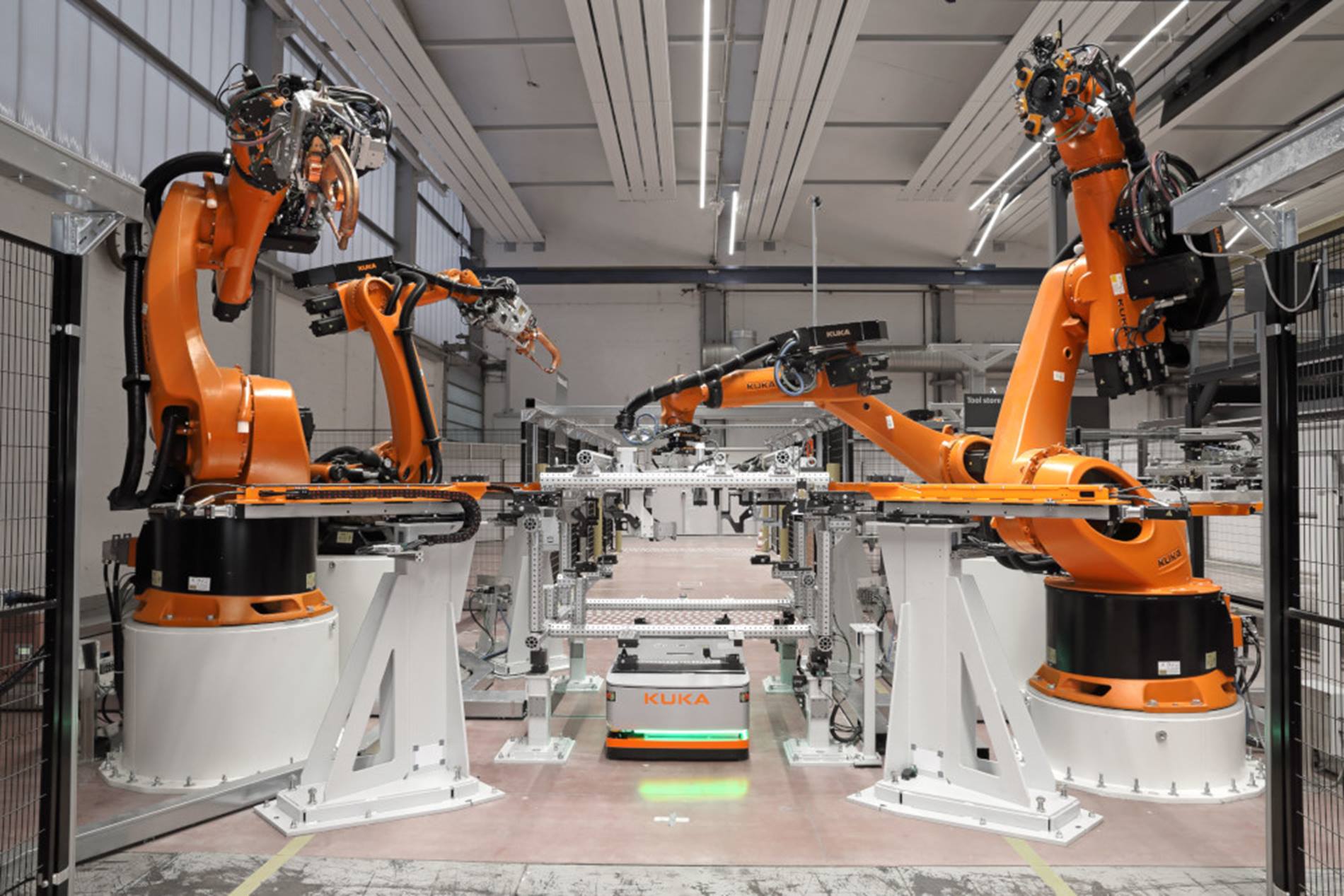

A smart solution is needed. That is why KUKA has developed matrix production: together with the automated guided vehicles (AGVs), the KUKA SmartProduction_control software package, which is based on artificial intelligence (AI) technologies, ensures, among other things, that production is flexible and versatile. A product-neutral production facility requires the separation of production and intralogistics. The decoupling of intralogistics from production is another key advantage of smart matrix production. Controlled by KUKA SmartProduction_control, the AGVs fetch tools from a tool store and then transport them in to the production cells that are to be equipped. At the same time, the AGVs move to the centralized material warehouse, which is decoupled from production, in order to transfer the centrally-stored components required for the production process into the cells. Matrix production can thus become a decisive competitive advantage compared with rigidly linked production concepts.

With the configurable production cells, combined with the freely programmable intralogistics and our new KUKA SmartProduction_control software package, we are able to provide our customers with everything they need for flexible and versatile production.

Smart manufacturing with KUKA matrix production

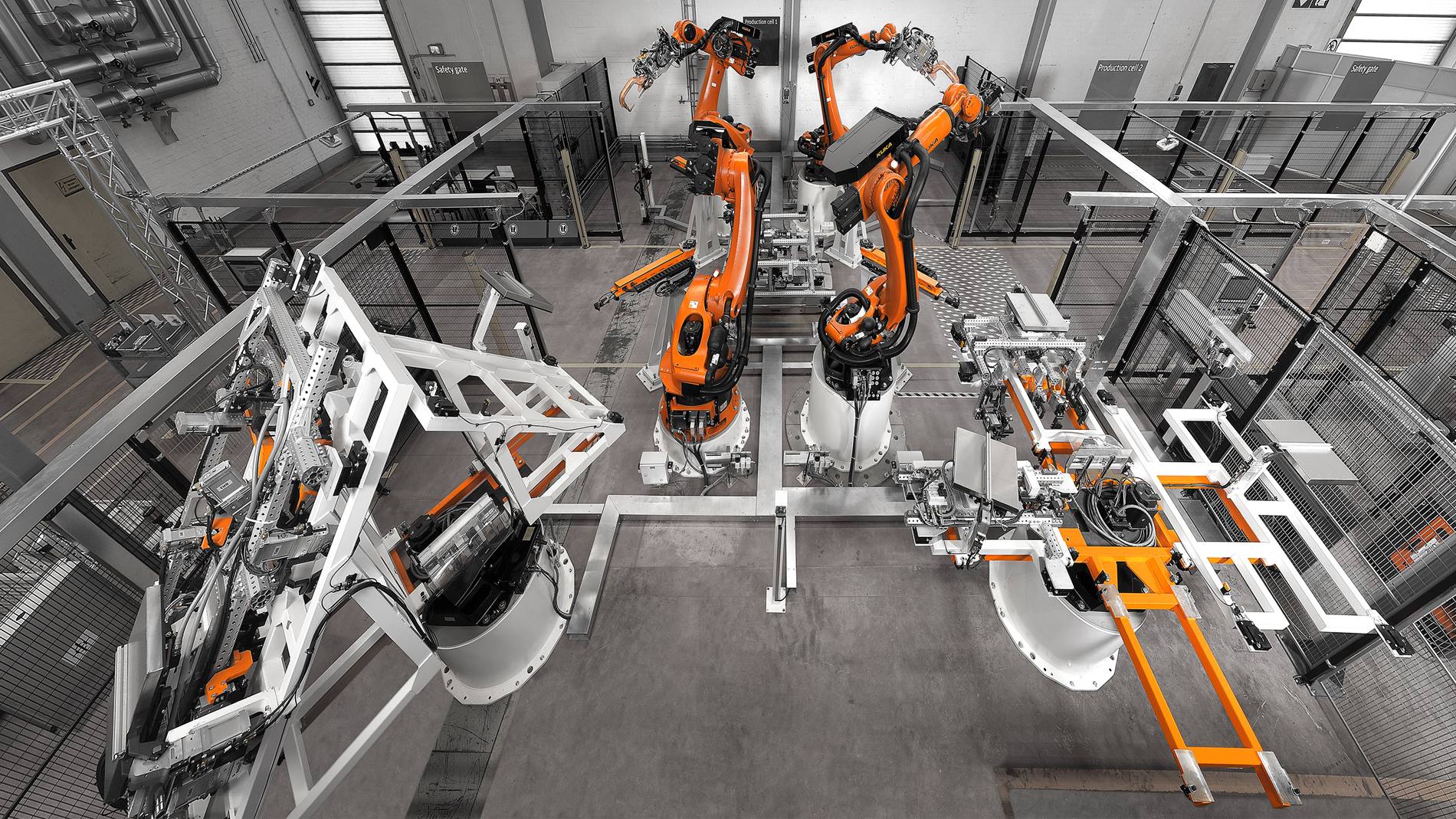

In order to demonstrate the principle of matrix production to our customers, a pilot system has been built and is being put into operation with the opening ceremony on 20 March 2018. Here customers can experience the matrix concept at first hand. It is based on standardized production cells. All cells are equipped with product-neutral basic functions and can be simply expanded with product-specific tools depending on the level of orders and batch sizes.

Fully automated intralogistics with AGVs

Advantages of the matrix production concept at a glance

The versatility of the system is perhaps the most decisive criterion. In this way, we can meet customer requirements. We are at the forefront of developments in this field.

The system is converted within a short time. Compared with previous rigidly linked production, the production facility requires the same space, but can be optimally distributed within that space. Due to the centralized logistics, less personnel is directly tied to the system and to the logistics. Furthermore, intermediate storage areas and material provision at the system are dispensed with. Matrix production is therefore also more cost-effective. Why? The entire value chain is networked, thereby enabling holistic optimization of the system.

Conclusion: Production becomes more flexible, competitiveness is increased and cost-effectiveness is improved.