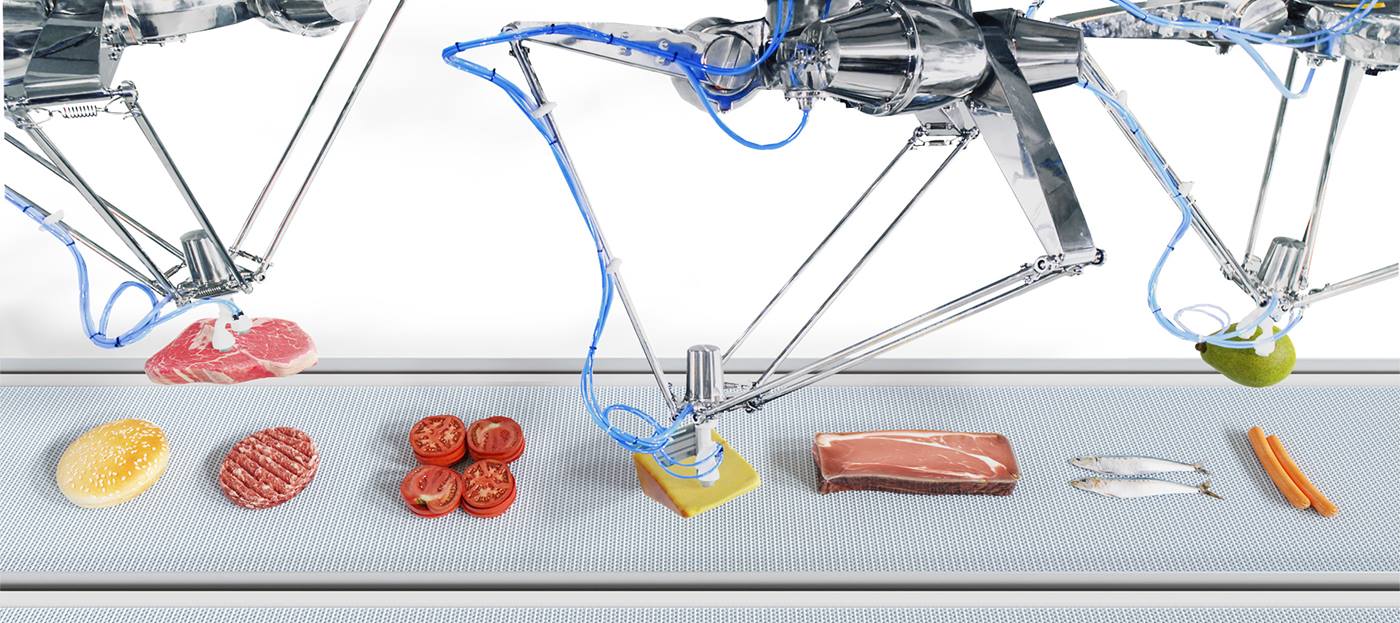

Safely lubricated: industrial robots with NSF H1 class food-grade oil in all axes

KUKA takes a consistently holistic approach. All axes of the HO robotic use food-grade lubricants, as does the energy supply system, which scores with food-safe NSF H1 greases. This provides consistent H1 lubrication (NSF approved) throughout the entire process chain – not only in production machines and conveyor systems, but also in the industrial robots themselves. Any incidental food contact is harmless to humans, and the light gray surface of the equipment easily reveals contamination.