Precise sorting of clutch discs for the honing machine

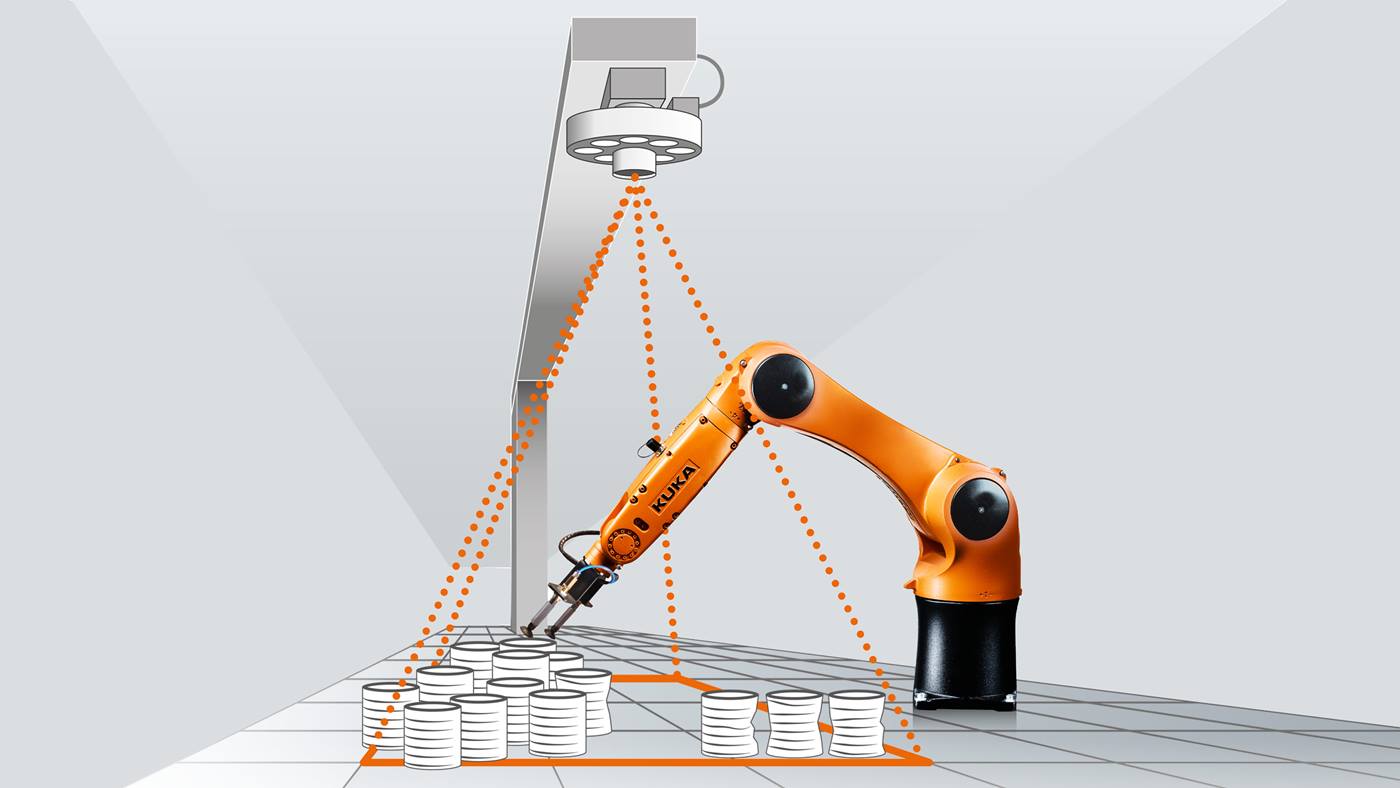

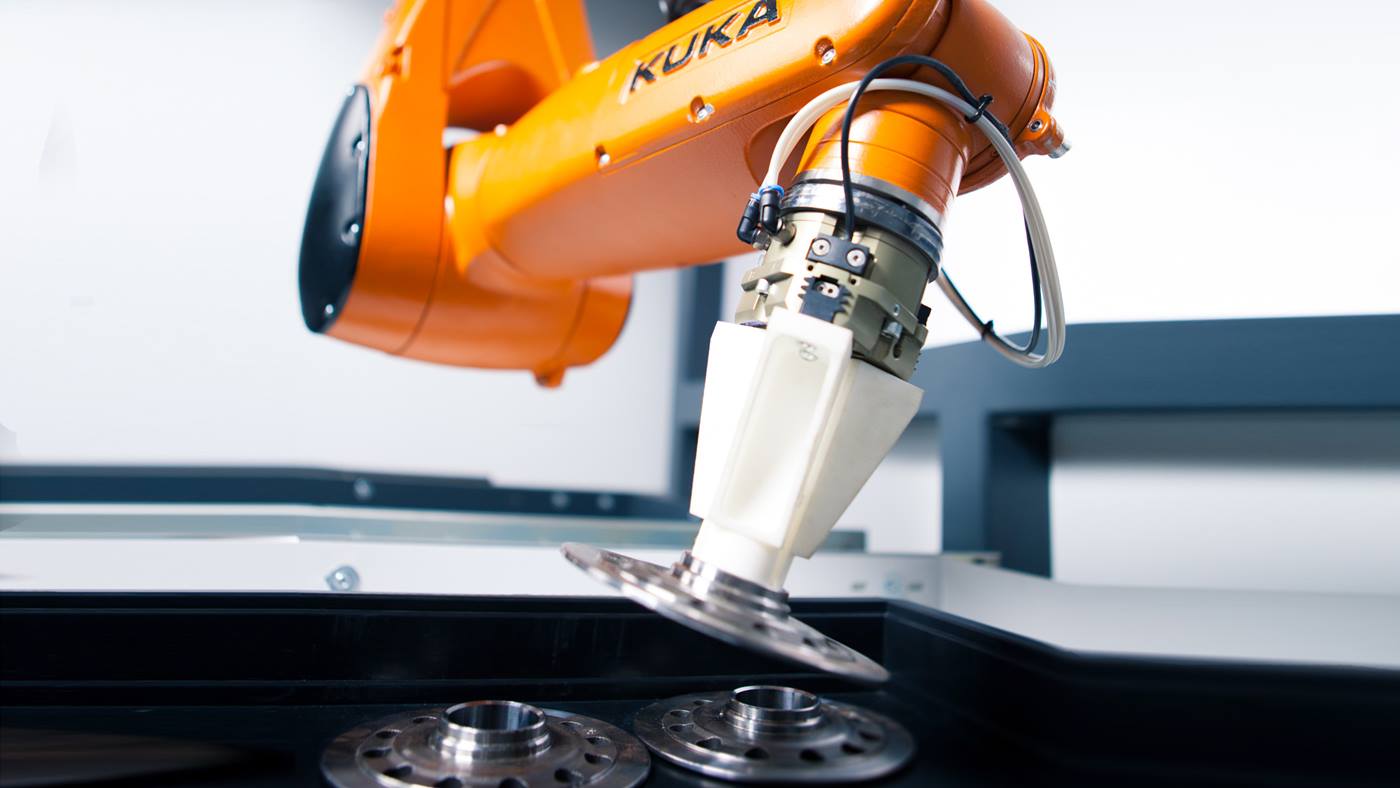

Based on the transmission of coordinates from a 3D vision sensor, a KUKA small robot from the KR AGILUS series precisely picks up unsorted clutch discs out of wire baskets and transfers them to the honing machine for further processing.

Designed for extremely high working speeds, the small robot has a maximum payload capacity of 6 kg and a reach of approximately 901 mm. The robot will be used in three-shift operation, with the possibility of covering one shift without personnel. The solution ensures that the clutch discs are set down consistently and precisely. This is made possible by the 3D vision sensor, which detects the exact location of the clutch discs and transmits the coordinates directly to the robot. The KR AGILUS then picks up the part from the wire basket before accurately loading it into the honing machine for further processing.

HBi Robotics designed the solution to allow it to be deployed in a different location as well. If the product is discontinued, the system can be easily reprogrammed accordingly. Use in combination with another machine tool is also conceivable. “Thanks to the precise analysis of motion sequences by means of 3D position detection, obstructions are detected in advance. Beyond this, the cycle time of a complex automation system can be determined exactly,” sums up Harald Bader, founder and CEO of HBi Robotics GmbH. He adds that customers from the automotive industry have also found these characteristics so convincing that further automation solutions are already being planned.