Comprehensive and efficient

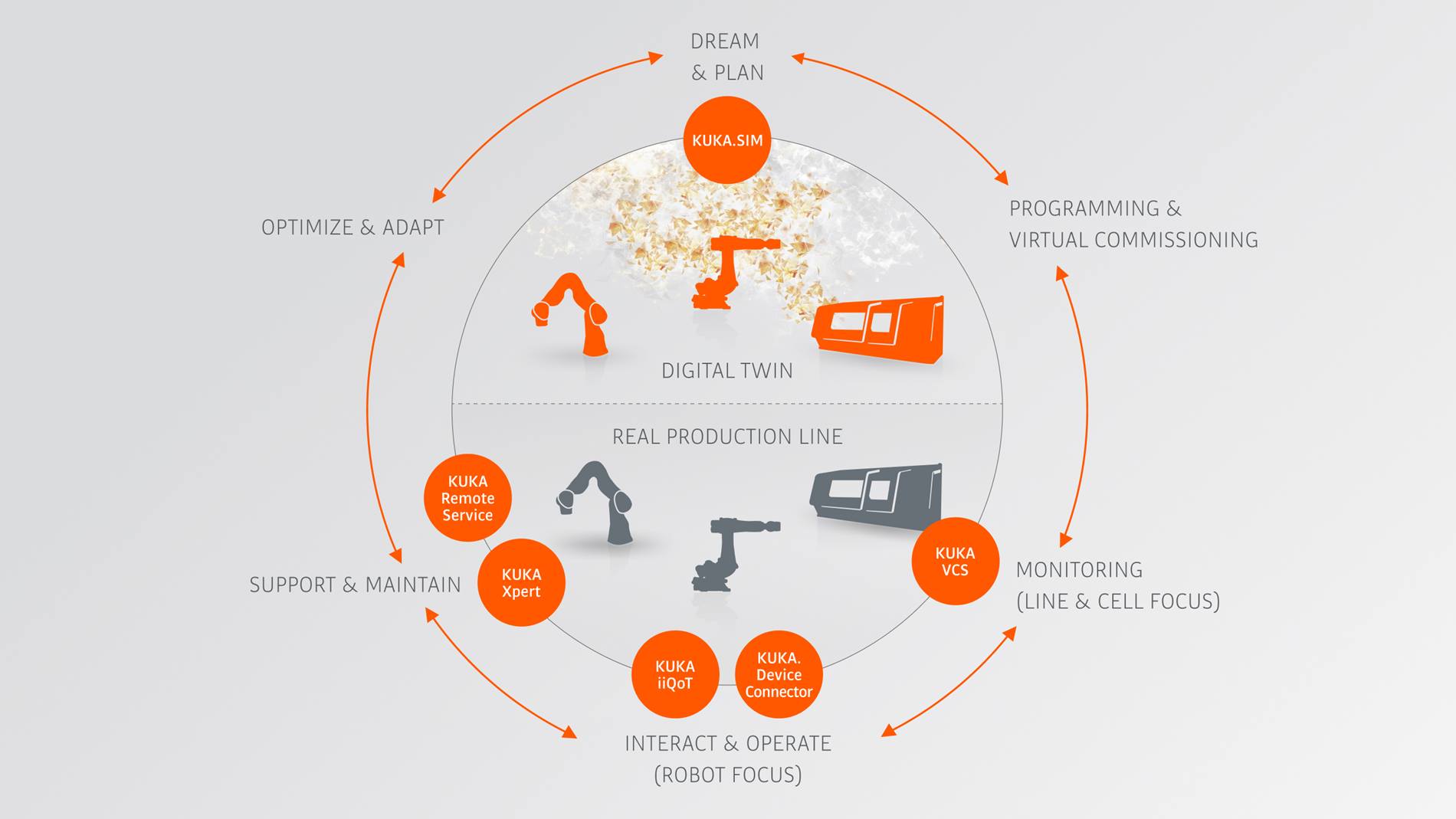

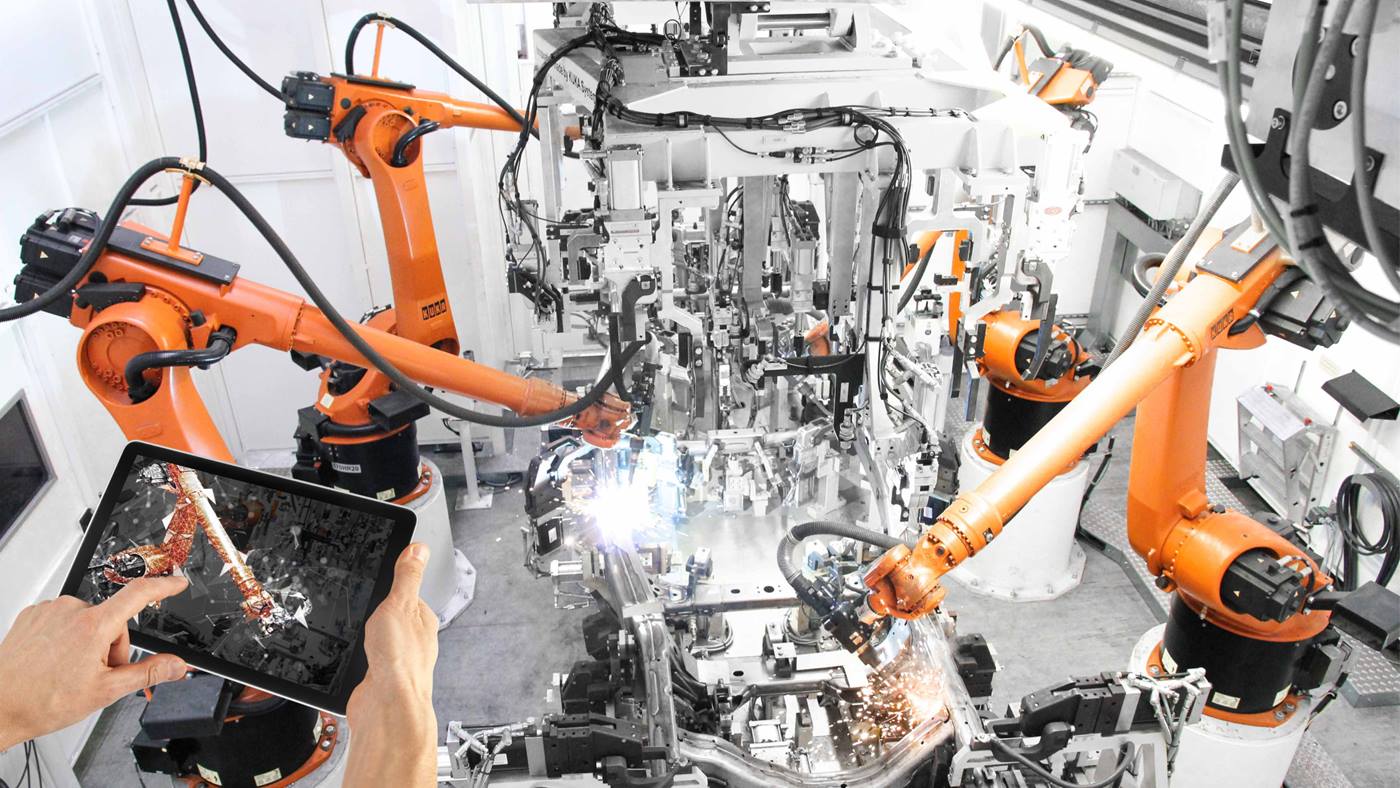

Whether for planning systems, commissioning and monitoring, optimizing ongoing operations or hands-on support: our digital services cover all phases of the value chain.

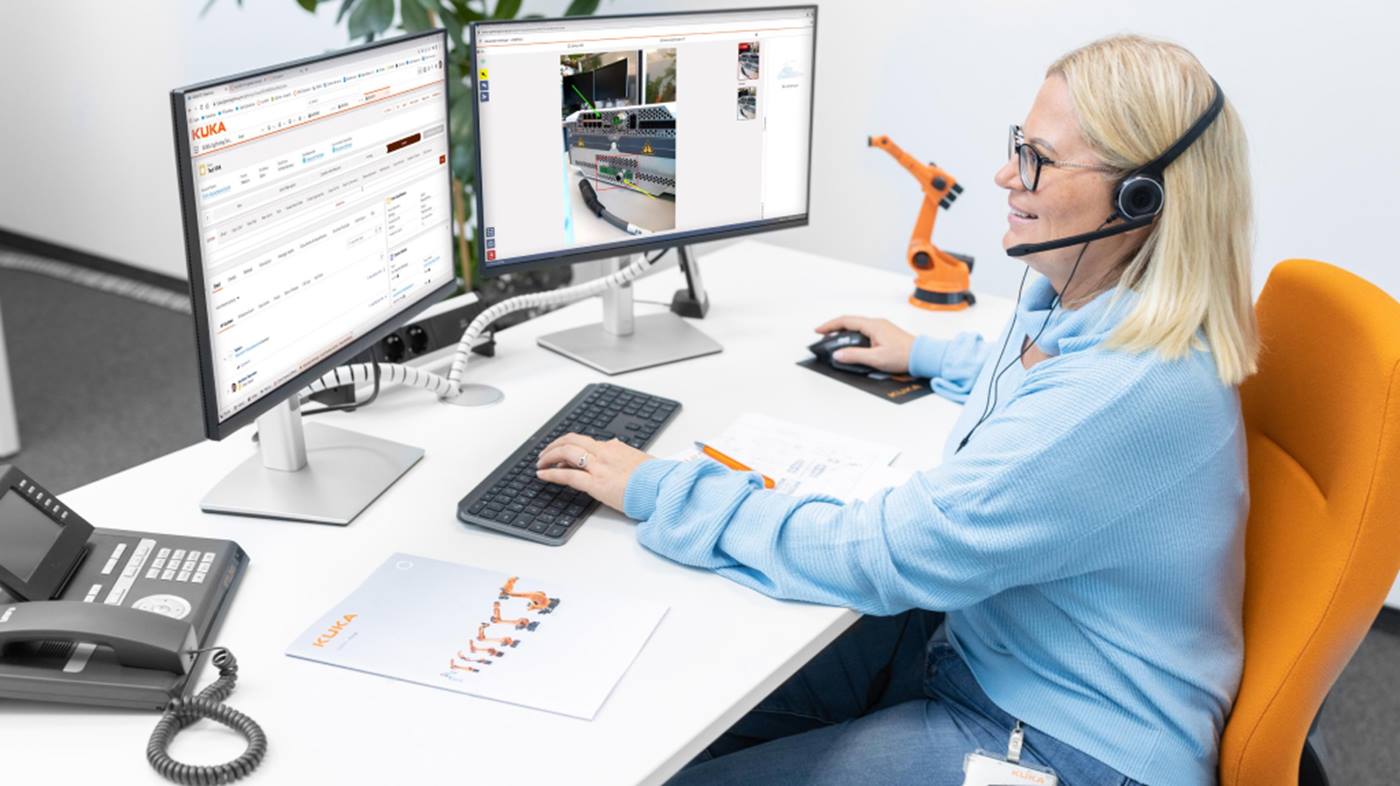

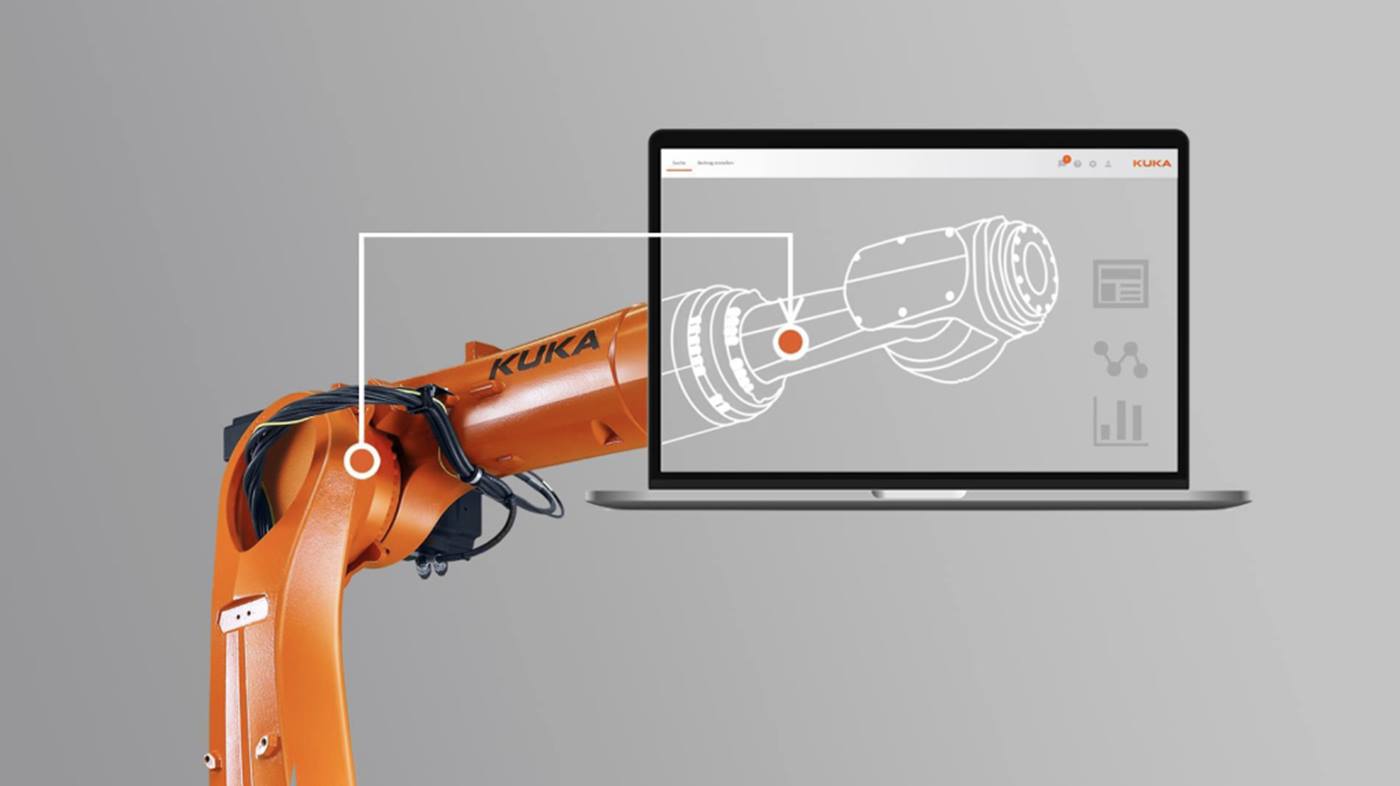

With tailor-made services, you can optimize your robot fleets as well as the management, maintenance and safety of your systems. You ensure that errors are detected immediately and corrected efficiently. You receive important notifications at any time, can gain a clear overview and can also have remote access if needed. And not least, you increase efficiency because with the right service you safeguard the productivity of your system, unlock potential for improvement and thus enhance the overall performance.