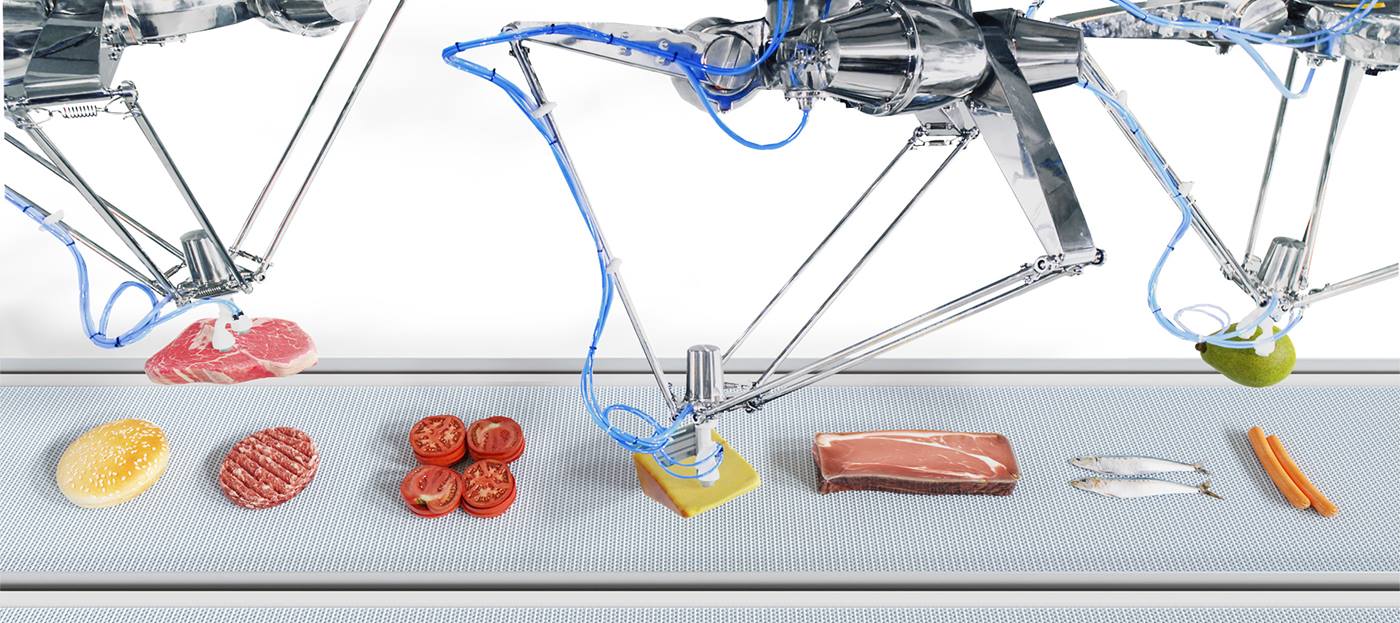

Patented packaging solution for food handling

The sandwich market is growing and growing. The sale of hygienically packaged slices of bread alone, in bags or containers as well as boxes, generated 13 billion U.S. dollars in revenue worldwide in 2018. According to experts, this figure is set to rise to 18.2 billion U.S. dollars in 2025. Incidentally, a third of this is accounted for by the U.S., which has the world's biggest appetite for sandwiches. But even in Great Britain, which is considered the home of sandwiches, this meal still has a special significance. According to the British Sandwich Association, a total of eleven billion packaged sandwiches are bought or freshly prepared here every year.

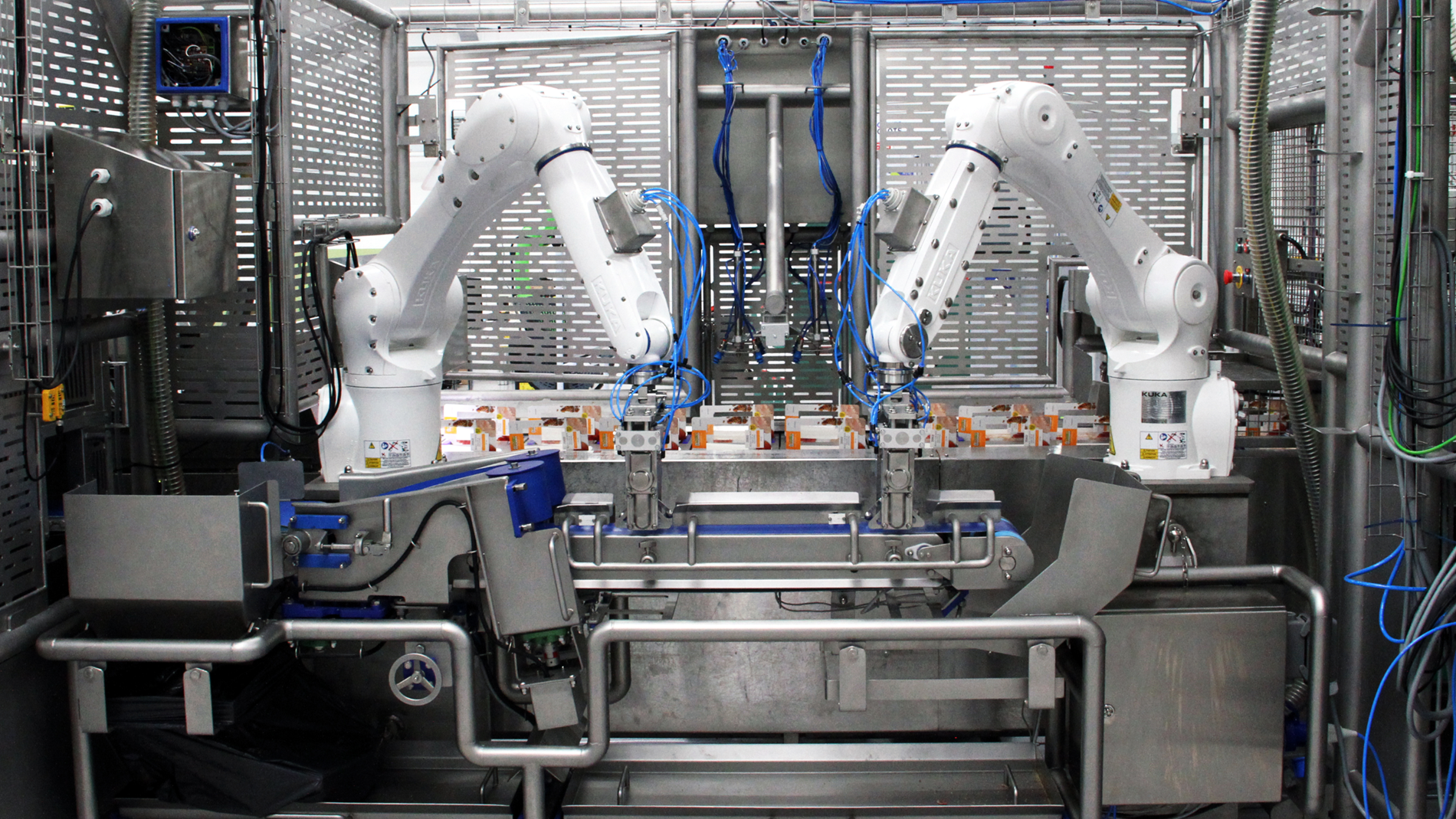

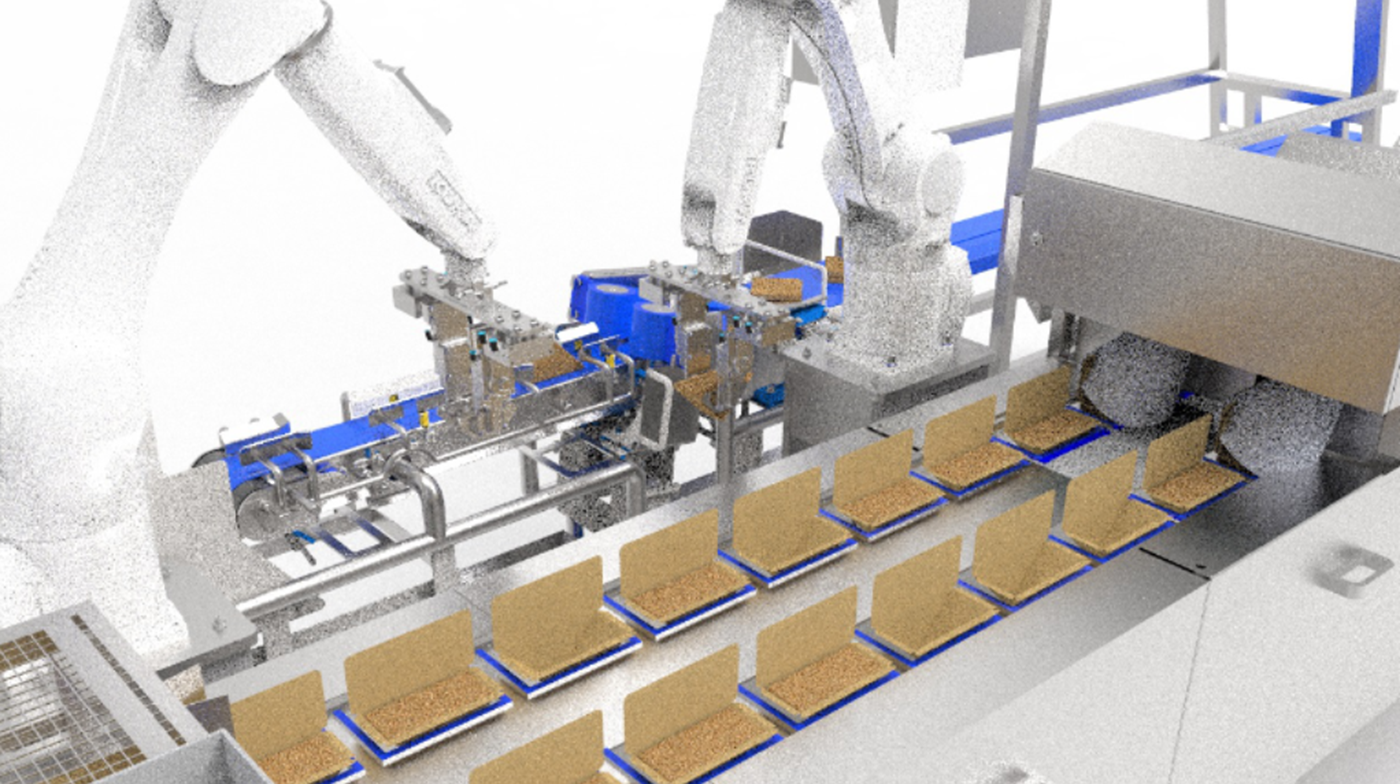

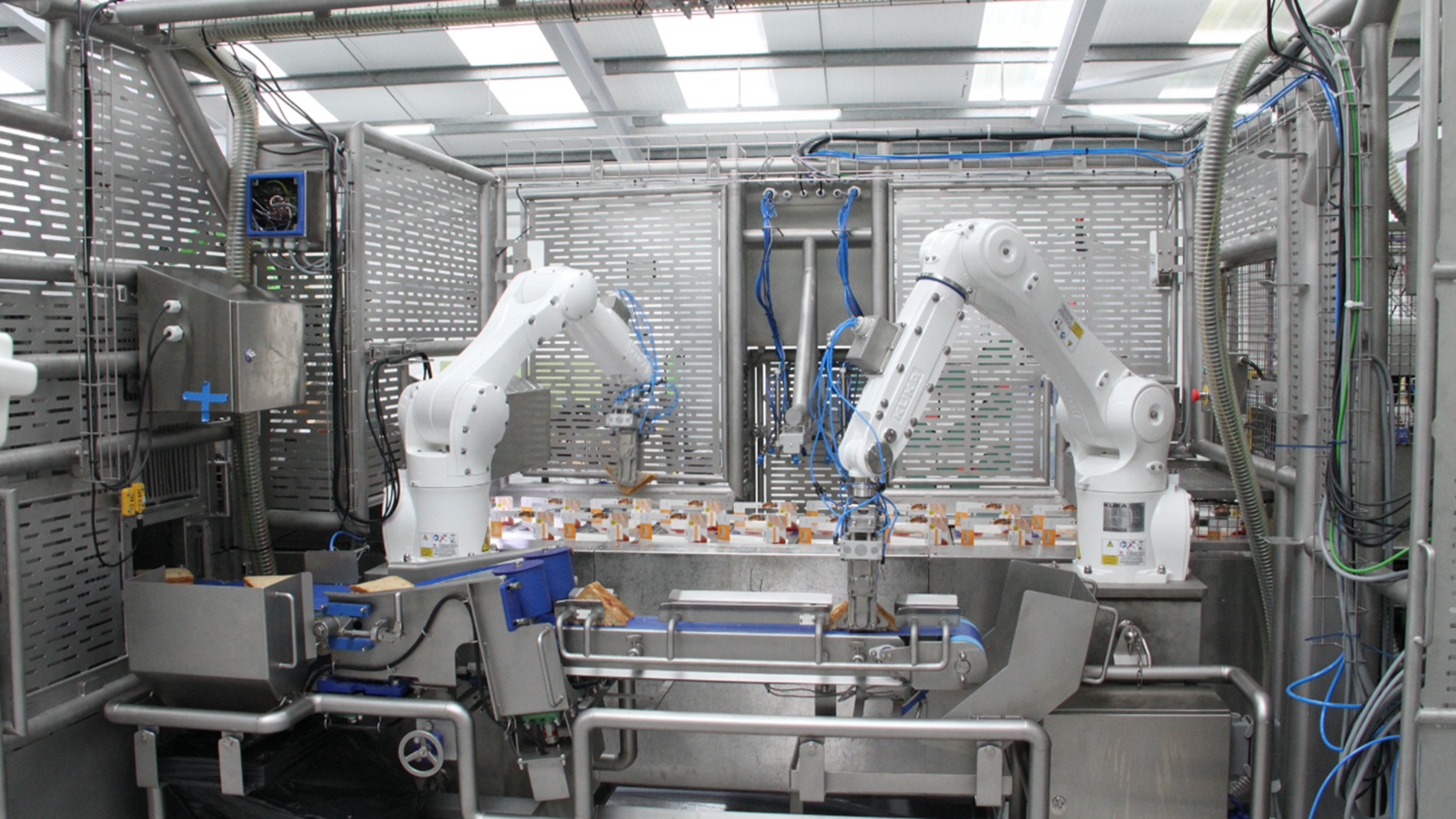

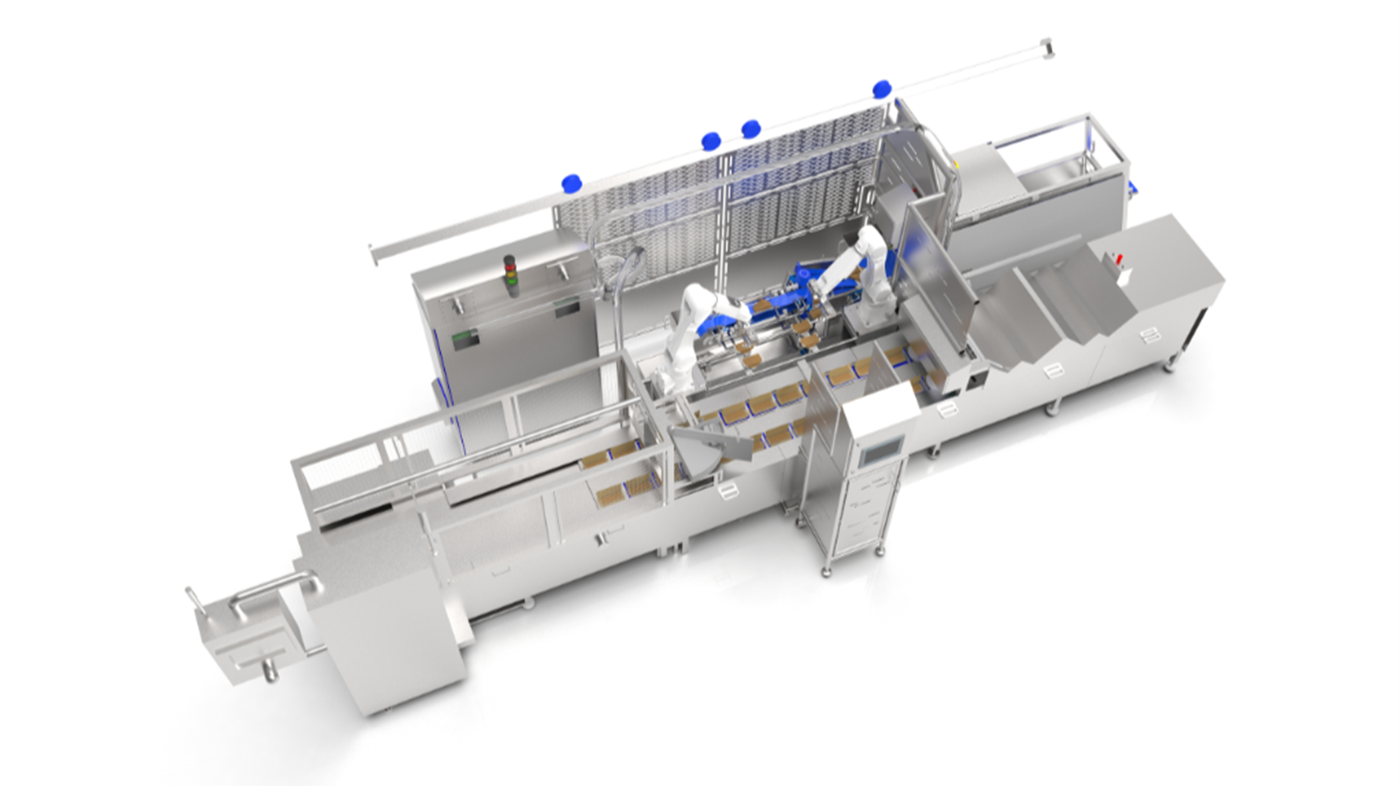

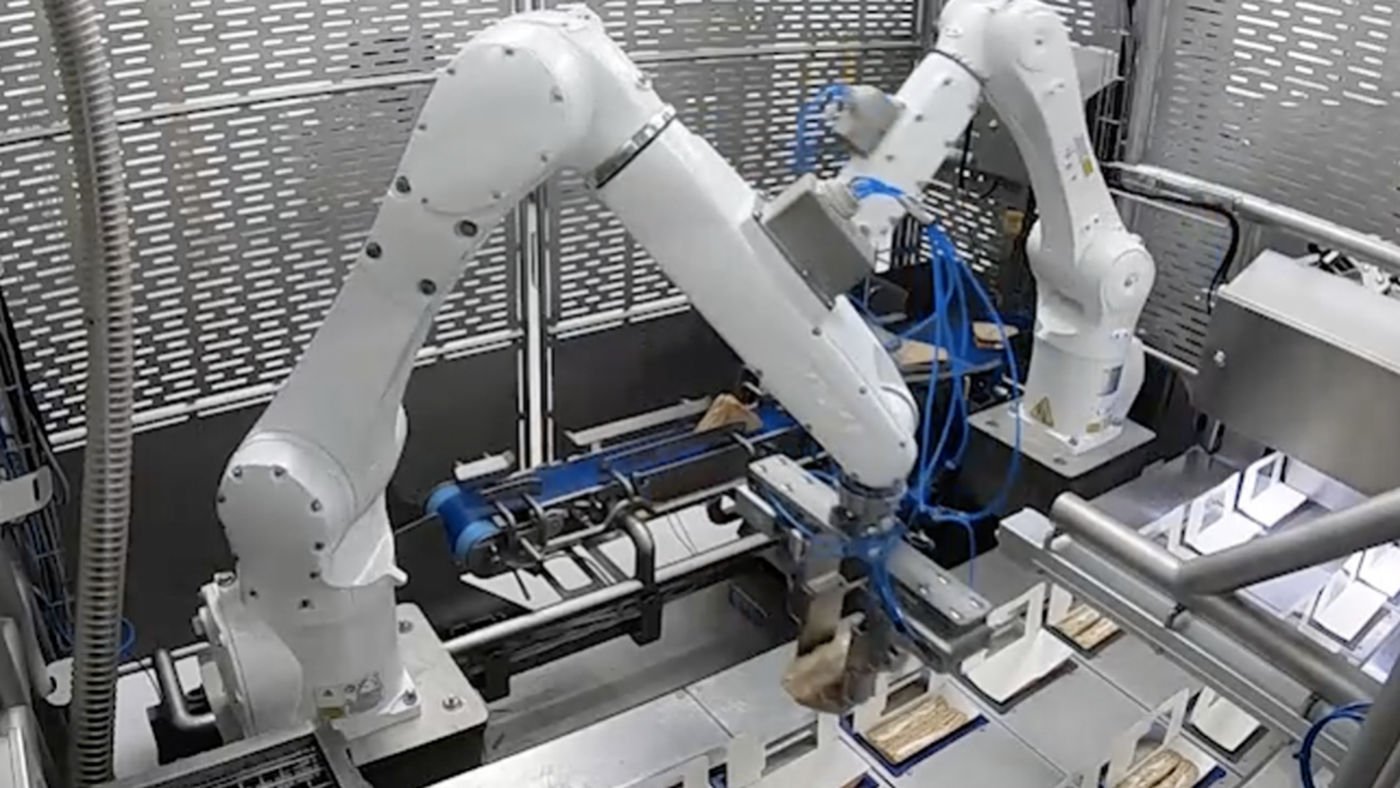

KR AGILUS HM well suited as a packaging robot

Whether it's the classic sausage and cucumber sandwich, with cheese or with bacon and egg: billions of slices of toast have to be topped, cut and packaged in plastic, paper or another material. For the last two steps, the British system integrator Active8 Robots has developed an automated solution in which the tasks are performed by two KR AGILUS HM, among others. The company, which has twelve employees, began the first tests back in 2017. Today its sandwich packing solution is patented.