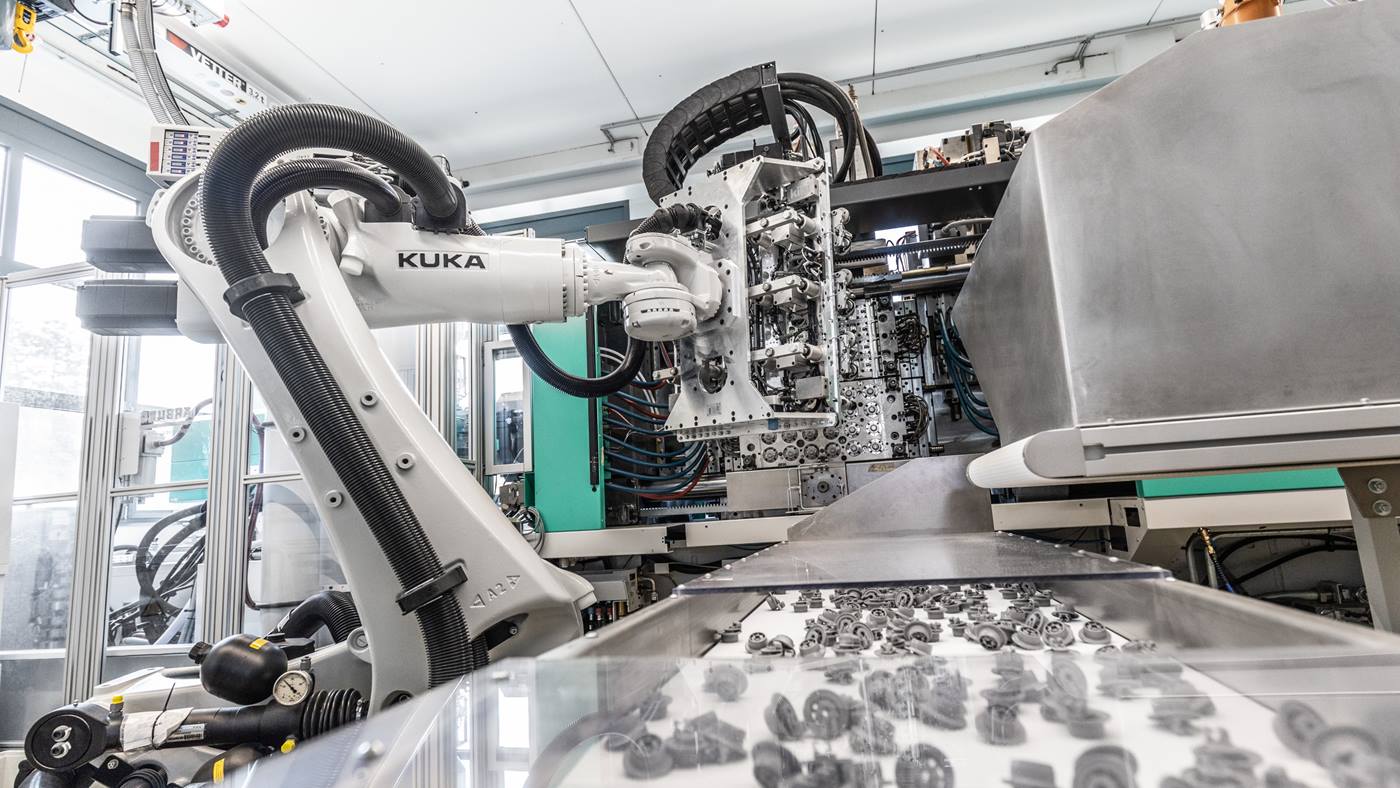

Automatic palletising and depalletising

With the world’s largest portfolio of palletising robots, palletising software and comprehensive services, KUKA offers perfectly matched solutions for robot-based palletising and depalletising in a wide range of industries.

Selection of customer examples from diverse industries – the combined expertise of KUKA and Swisslog

From mono-palletising to intralogistics: KUKA automates robotic palletising processes for the entire supply chain

Mono-palletising

For handling unmixed packages, KUKA offers not only various robotic palletisers but also the conveyor and palletising software KUKA.PalletTech for particularly straightforward configuration and fast start-up of your robotic palletising system.

It enables you to carry out the stacking and feeding of such items as:

-

Vegetable crates

-

Frozen fish

-

Trays with chicken eggs

-

Beer crates

-

Water canisters

Mixed palletising

For challenging mixed case palletising, we offer various high-speed solutions such as complete conveyor systems from Swisslog or software solutions from our global network of system partners, each of which is tailored to KUKA machines and enables smooth integration.

Possible areas of application:

-

Picking goods e.g. in the beverage industry

-

Store-specific pallet layout

-

Automatic stacking of goods on a pallet according to weight, size and pressure sensitivity

-

Repalletising in goods distribution centers

Depalletising

For automatic depalletising, you can use KUKA.VisionTech to detect the position of displaced cartons. Automatic end-of-line depalletising systems offer possibilities to optimize your flow of goods in logistics, e.g. when filling your production lines or, as in the video shown, the optimal utilization of truck tours. Using the so-called goods-to-truck method, the grain sacks are fed to the trucks in such a way that the loading corresponds exactly to the orders of the bakeries along the delivery route. This also significantly reduces the amount of heavy manual work for employees.

Examples of depalletising include:

- Unloading empty glass containers

- Depalletising grain bags for loading onto trucks

- De-palletise empty pallets and empties

- Dismantling pallet stacks and distributing the unladen pallets

- Automated unstacking of small load carriers

Cold storage palletising

Even at sub-zero temperatures down to minus 30 degrees Celsius, the KR QUANTEC PA robot in the Arctic version palletises quickly, precisely and without a protective cover. Its great reach allows for short cycle times and high-performance during the automatic stacking and setting down of items in a frosty environment. The palletiser also ensures that an uninterrupted, automated cold chain is maintained.

It enables you to carry out the stacking and feeding of such items on pallets such as:

-

Frozen vegetables and frozen herbs

-

Ice cream

-

Meat and poultry

-

Frozen pizza

Light Palletising fenceless and with fence

For the flexible handling of light to medium-weight products light palletising is used in the consumer goods industry. Products are efficiently stacked on pallets from the conveyor belt. The compact design of the location-independent palletiser system saves valuable space and allows easy integration into existing production and storage environments. Compared to heavier industrial palletising systems, the application for light palletising is more cost-effective in terms of both purchase and operation.

Lightweight pelletising can be implemented in a cell or fenceless. The conventional palletizers in a fenceless environment is equipped with the pressure-sensitive safety skin AIRSKIN. KUKA offers the robot series LBR iisy Cobot, KR CYBERTECH and KR IONTEC.

Find out more about the fenceless palletising solution with AIRSKIN

Key benefits of lightweight robotic palletisers include:

- Space saving thanks to compact design

- Seamless integration into existing environments

- Cost efficiency thanks to simple design

- Enormous adaptability to a wide range of production requirements

Mobile pallet logistics

For the efficient design of logistics processes KUKA offers a broad portfolio of autonomous mobile robots (AMR). In contrast to conventional industrial trucks, AMRs can move independently through your production halls, recognize obstacles safely and drive around them. In addition, VDMA 5050 compatibility enables the existing vehicle fleet to be expanded as required.

Possible palletising solutions include:

- Material transport automation between production stations

- Flexible adaptation to the warehouse structure

- Optimization of warehouse handling and goods flow

- Pallet movement between vehicles

Palletising solutions for increased competitiveness

24/7 access to product information and services concerning robot-based palletising

In the my.KUKA digital customer portal, you can check product data and product availability at any time, order hardware and software products, manage licenses and support requests, and much more.