Speeding up processes, relieving employees of monotonous work and protecting customers

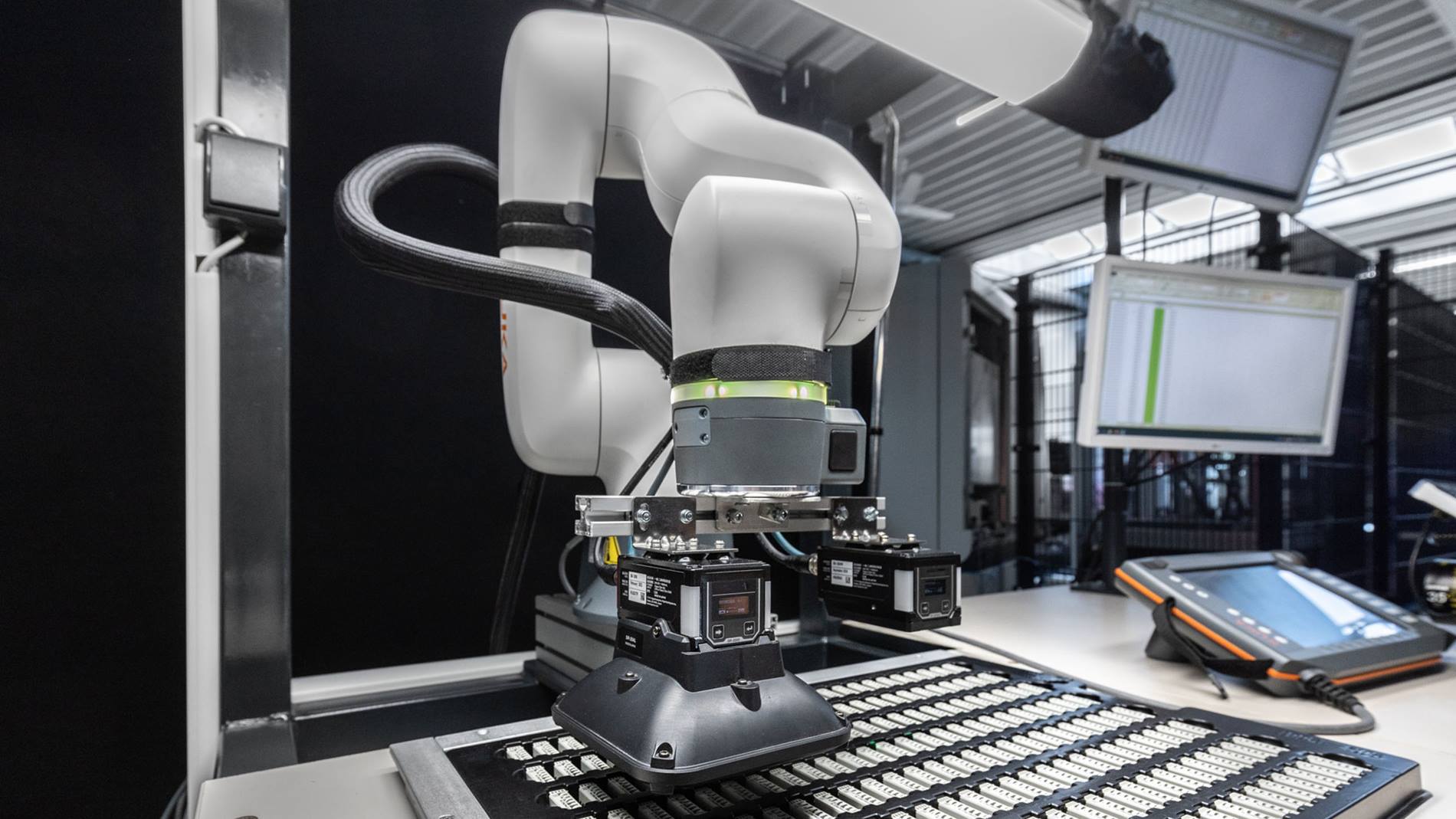

This type of quality control for DMCs was much more time consuming in the past, says Tim Hertz. “To check for completeness, we had to scan each part individually. An employee had to remove all the components from the tray, scan them, and then put them all back again." Now, with the LBR iisy robot on the job, the inspection and quality assurance processes are much faster and more precise.

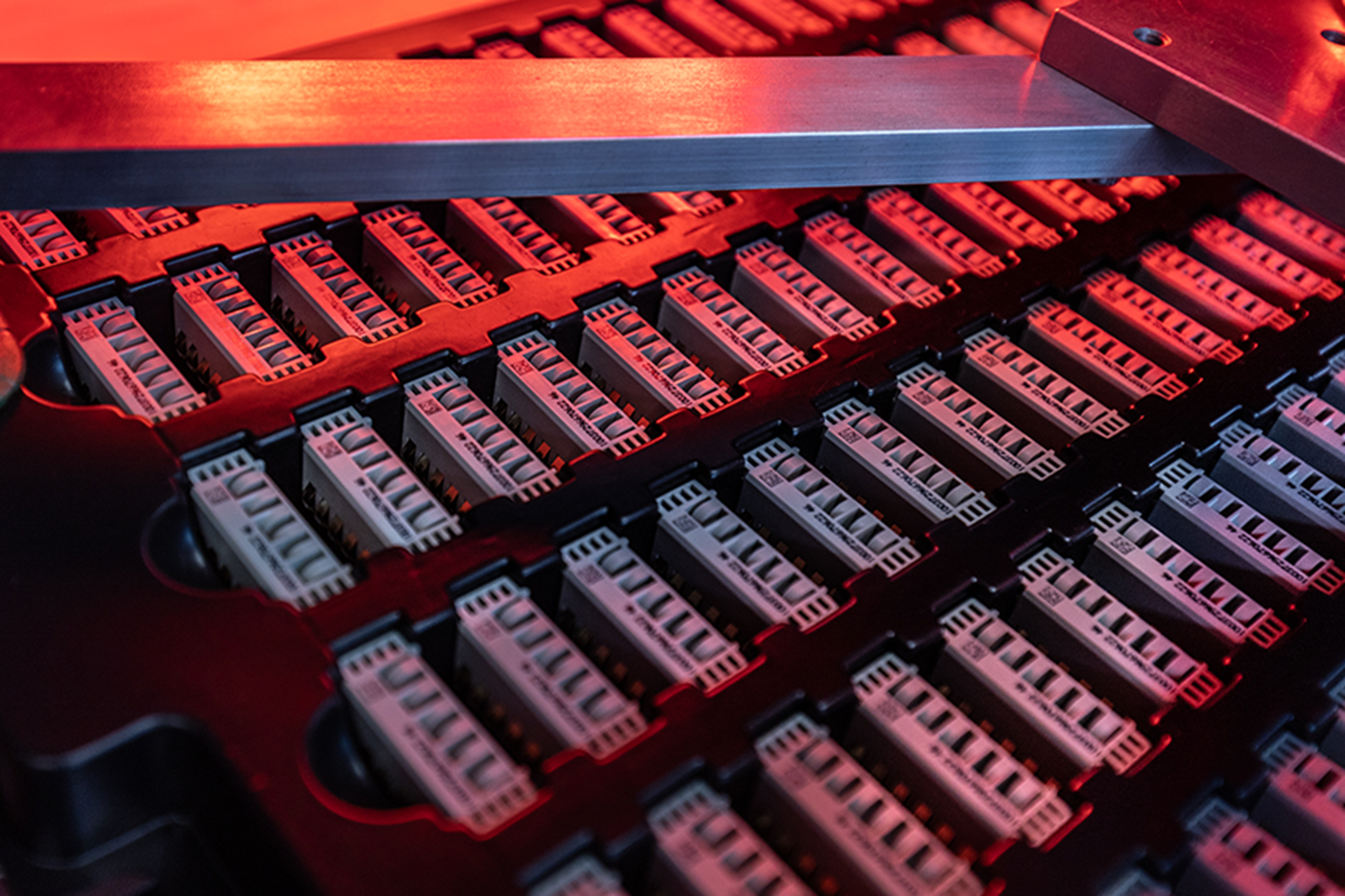

According to Bastian Fest, the customer – an automation company – specifically wanted an automated solution because installing a flawed bus connector in its controllers could prove costly. Bastian Fest reported, “The bus connector becomes the very first part of the controller. It is soldered, screwed onto a circuit board and the whole controller is built around it. So, if the Data Matrix code is poor, who will notice? The shipping department!” At the point the substandard part is despatched, the damage can be considerable.