Automation for arc welding with KUKA

KUKA offers a wide range of automation components, function packages and cells as standard products that are quickly available. They can be combined in a modular fashion and flexibly adapted to specific requirements.

All-round package for a perfect weld seam

From engineering to service as well as customized turnkey solutions for automated welding

Learn about the different arc welding processes

Gas metal-arc welding is an arc welding process in which an arc is ignited between an electrode and the component, fusing the workpiece and, if applicable, a filler metal. Here, a distinction is made between several methods. Among these, MIG/MAG welding and TIG welding are the most used methods for the process. These differ in the type of gas that is used and the choice of materials. They impress with maximum weld seam quality and a high welding speed.

MIG/MAG welding

MIG/MAG welding is an arc welding process in which an arc is ignited between a welding wire and the component, fusing the workpiece and the filler metal. To protect the weld pool from the reactive oxygen in the environment, a shielding gas is supplied with the welding wire. This displaces the oxygen at the welding point and thus prevents oxidation of the weld pool.

In metal active gas welding (MAG), an active gas, such as CO2 or a CO2 mixture, is used. The active gas reacts with the weld pool and stabilizes the arc.

Metal inert gas welding (MIG) uses an inert – i.e. non-reactive – gas such as argon or nitrogen.

Advantages

-

High welding speed

-

High deposition efficiency

-

Inexpensive

Application

-

MIG: alloyed and unalloyed steel

-

MAG: precious metals such as stainless steel, aluminum, titanium or copper

TIG welding

In tungsten inert gas welding (TIG), the welding current is supplied through a tungsten electrode, which is temperature-resistant and does not melt. As in MIG welding, inert shielding gases (such as argon or helium) are used to prevent a reaction with the oxygen in the air. If a filler metal is required for a specific application, it is fed separately via an external wire feeder.

Advantages

-

Excellent seam quality and appearance

-

Suitable for all welding positions

Application

-

All weldable metals

-

Thin-walled workpieces

Plasma welding

Plasma welding is a variant of TIG welding in which the arc is constricted by a water-cooled nozzle. In addition, a plasma gas, usually argon, is introduced to create a plasma that has a greater power density than the arc alone.

Advantages

-

Greater power density

-

Higher welding speed

-

Low distortion

-

Can be combined with external wire feed

Application

-

Micro-plasma welding (0.1 - 1 mm workpiece thickness)

-

Plasma welding with keyhole (3 - 9 mm)

-

Plasma MIG welding (3 - >10 mm)

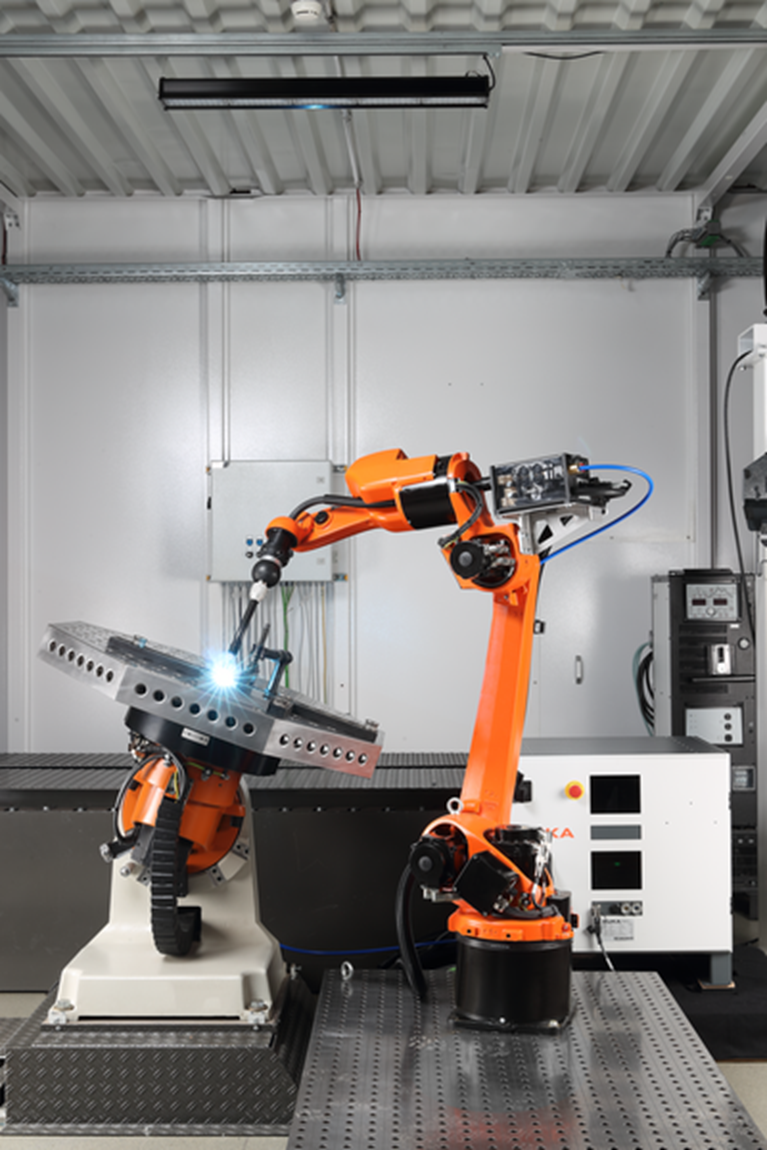

Welding robots, positioners and welding cells:

standardized modular components that can be ideally combined

Software and sensor technology – no matter how complex the welding task

- KUKA.ArcTech: software package with many functions for easy and fast operation and programming of the welding application

- KUKA.TouchSense: software for seam search and detection of shape and position deviations of metal workpieces

- KUKA.Sim: even more efficient creation of offline programs with the KUKA.Sim ArcWelding add-on for welding applications

- KUKA.ProcessScreen: software for the monitoring and documentation of process parameters

- KUKA.SeamTech: sensors for seam finding and seam tracking as well as correction of robot motion during the welding process

- KUKA.Tracc TCP: software technology package for automatic checking and calibration of the torch TCP in the production cycle

- KUKA.iiQoT is a central IIoT platform for data-based automation

- KUKA.AppTech offers predefined structures and program sequences for fast start-up of your welding application and provides modules for structured communication between the industrial robot and the programmable logic controller (PLC)

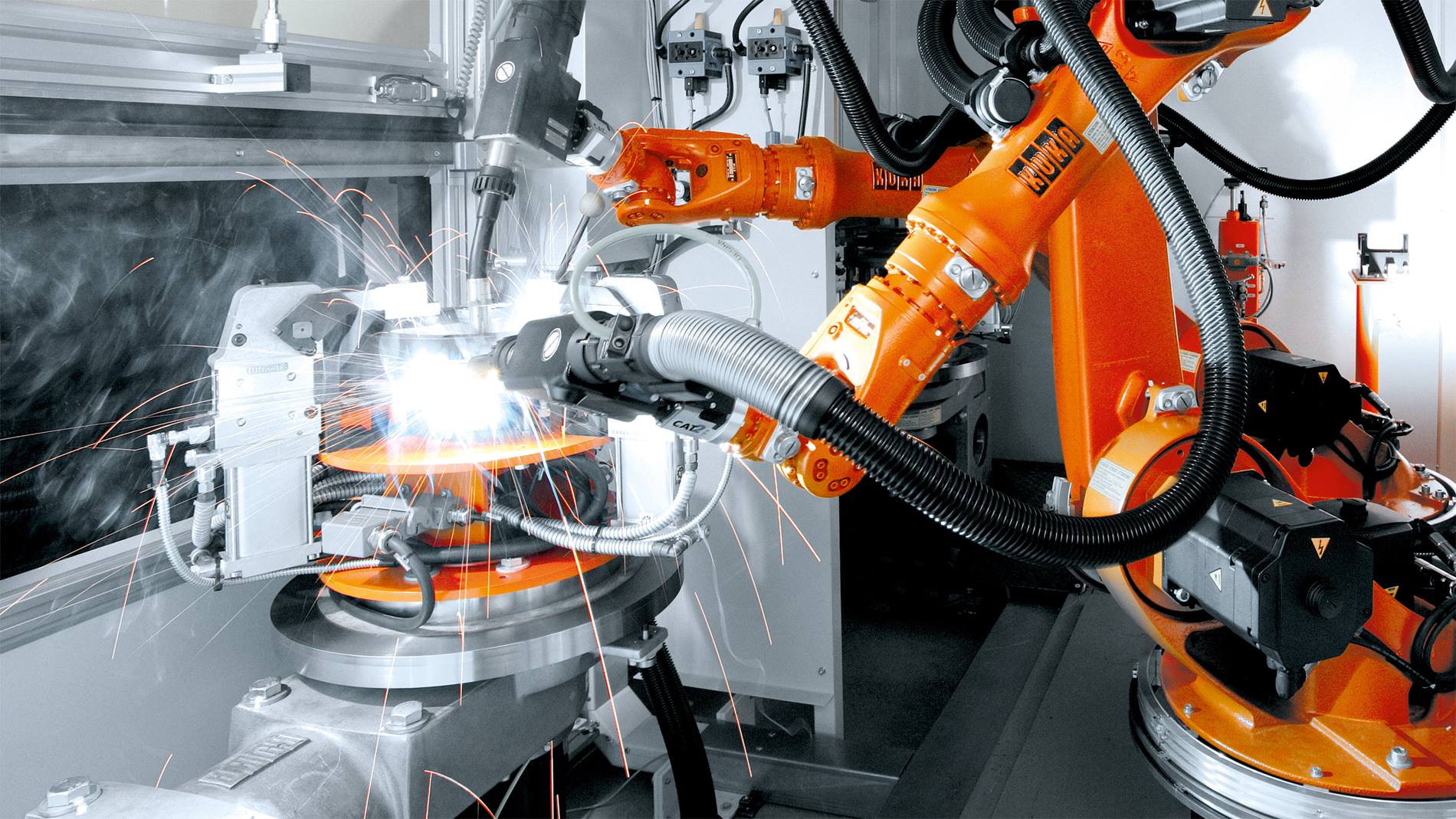

Strong KUKA partners for arc welding

Our robots achieve the best possible welding quality with the appropriate welding equipment from our strong partners such as Fronius, Kemppi, Miller, Lorch, Lincoln, EWM, SKS, ESAB and Migatronic.

The welding equipment is connected to the robot controller quickly and easily via a field bus interface, such as EtherCAT (present in every KR C4 controller). In this way, the full range of functions is available to the operator at all times.