From manual to automated: your path to robotic welding

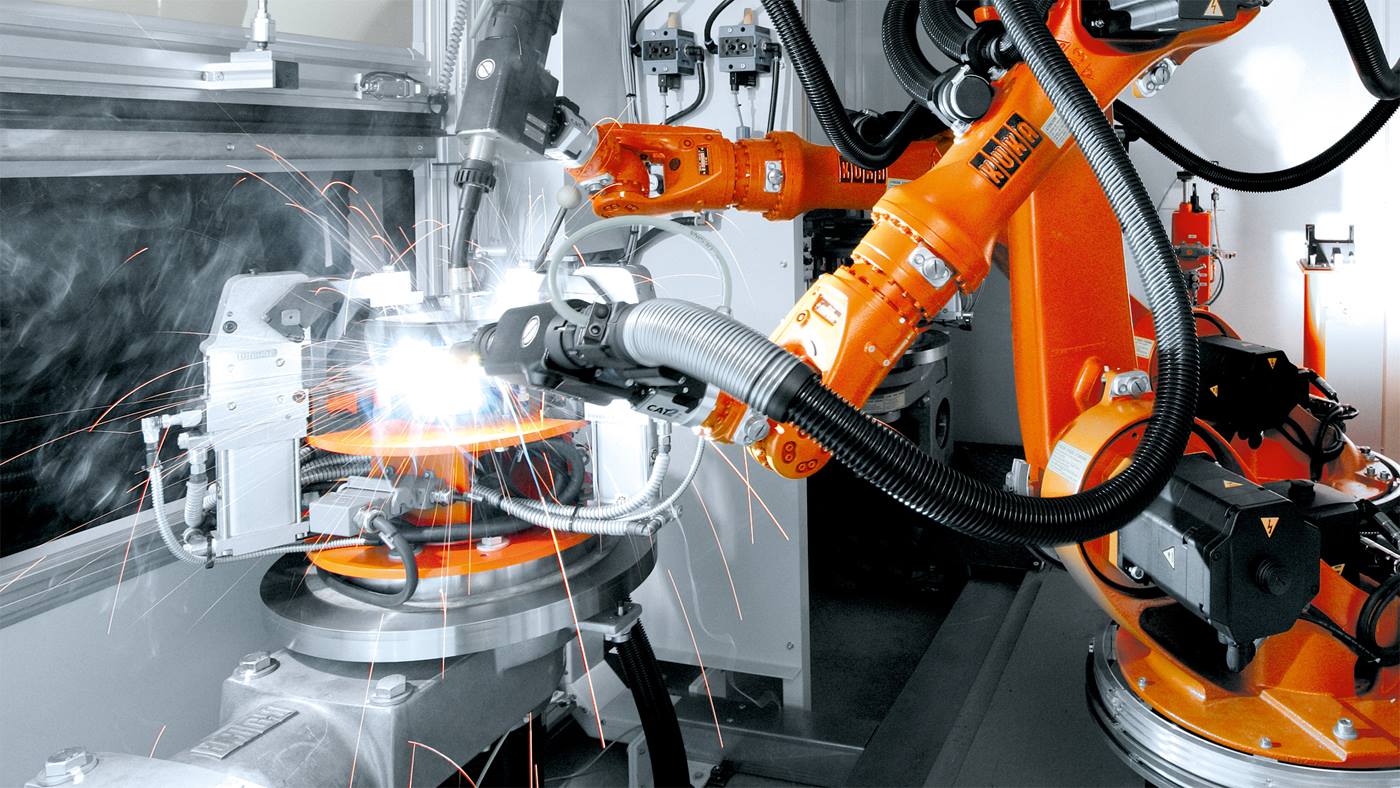

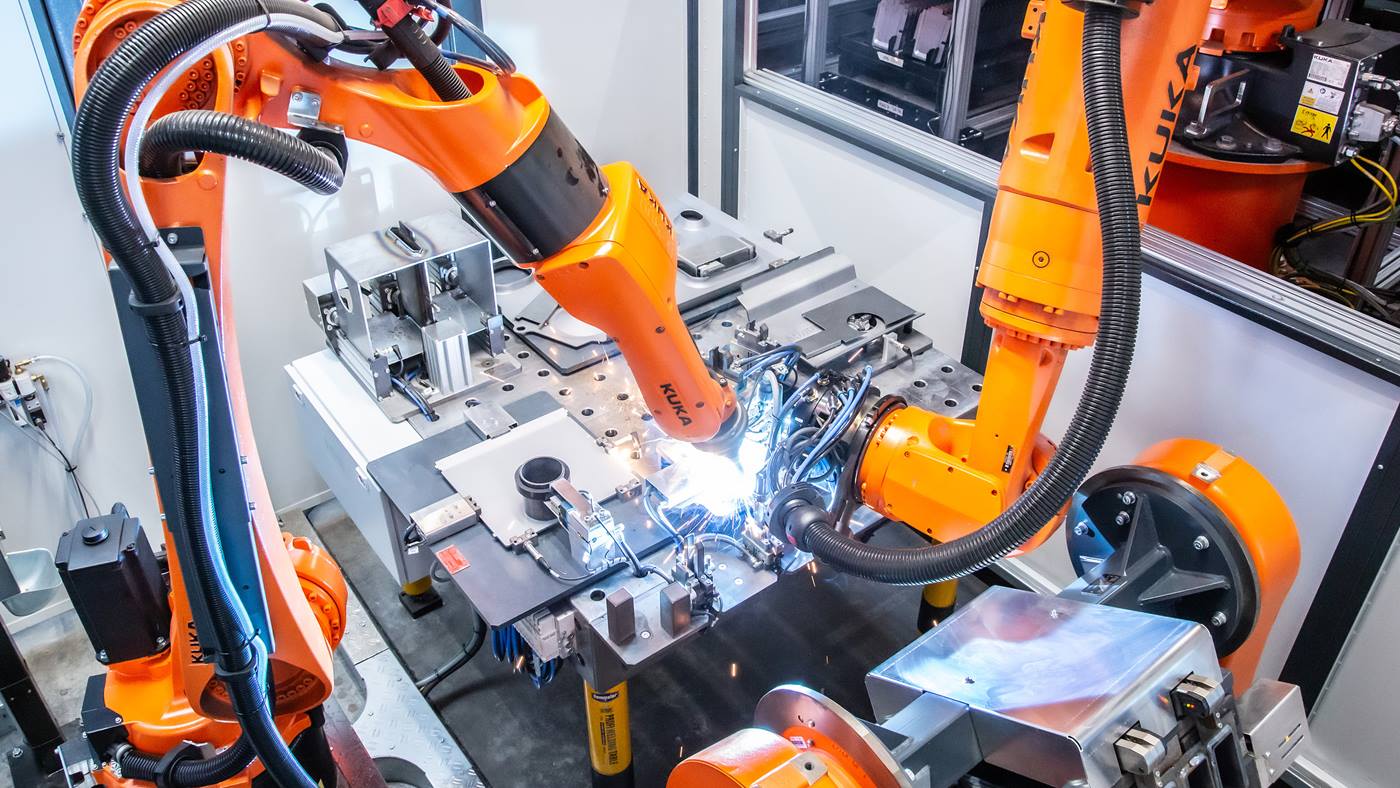

With flexible automation solutions for a wide range of welding processes – even for materials such as aluminum, bimetals, or difficult-to-weld raw materials – we support technology-driven industries such as automotive, supplier, and battery manufacturing in implementing future-proof manufacturing processes.

What types of welding can be done with robotic welding?

Welding robots are suitable for a wide range of applications, from TIG and MIG /MAG welding to special technologies such as magnet, plasma, and friction welding. Even automated welding of complex components and demanding materials is possible without any problems. We support our customers and integrators with expertise in the most important welding technologies as well as in automation and process optimization.

Expert knowledge from KUKA for all core processes of automated welding:

KUKA welding software: Easy programming, fast integration, flexible welding

→ Various software packages are available for MIG/MAG and TIG welding processes – from the configuration of different welding power sources and seam detection and tracking to a special seam search application for arc welding. An integrated system for automatic TCP control and calibration ensures precise tool alignment and exact positioning on the workpiece.

→ For spot welding, software solutions are available for servo gripper control, machining aluminum joints, and automatic gripper compensation without additional hardware.

→ Various software packages are used for laser applications , offering comprehensive functions for configuring and programming laser applications and for connecting laser welding and laser cutting systems.