Tier 1 Automotive Manufacturing

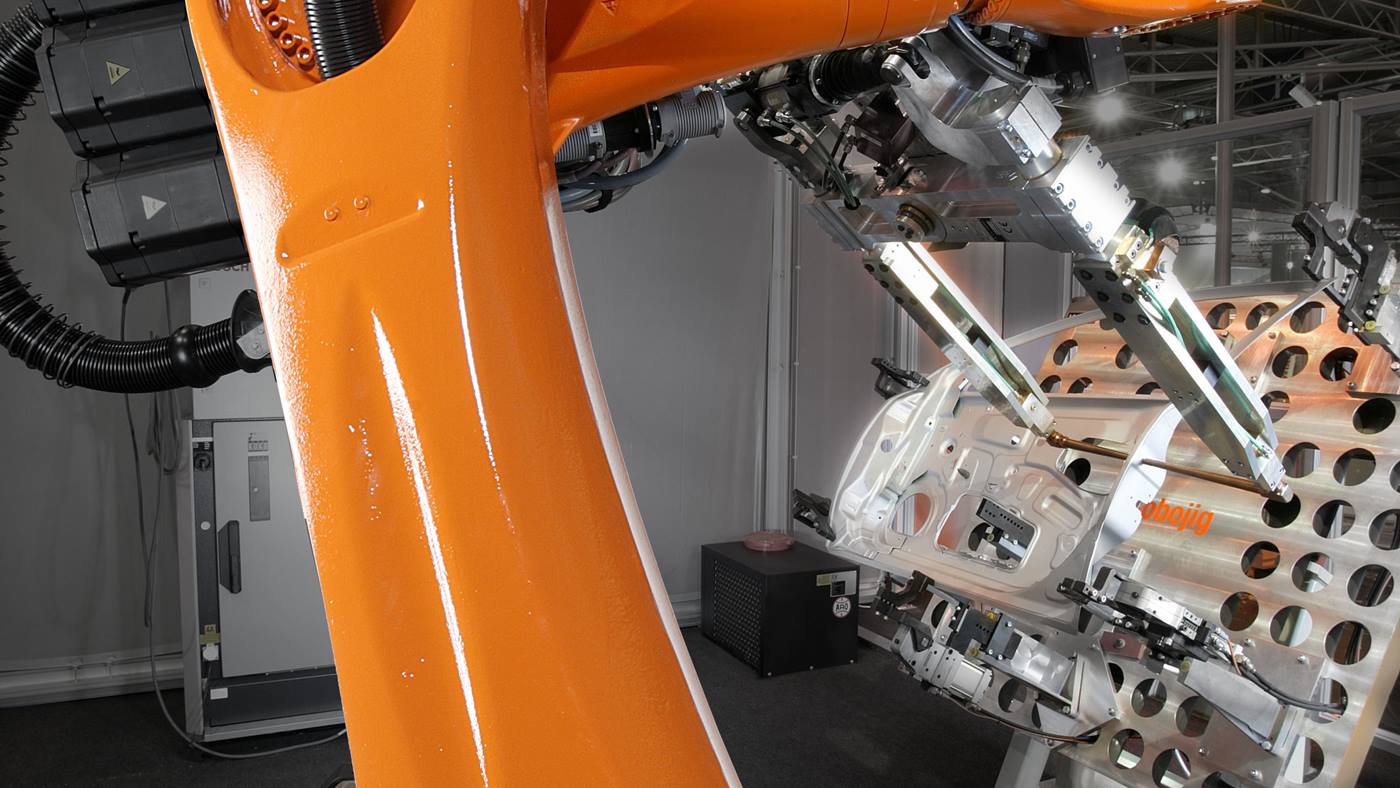

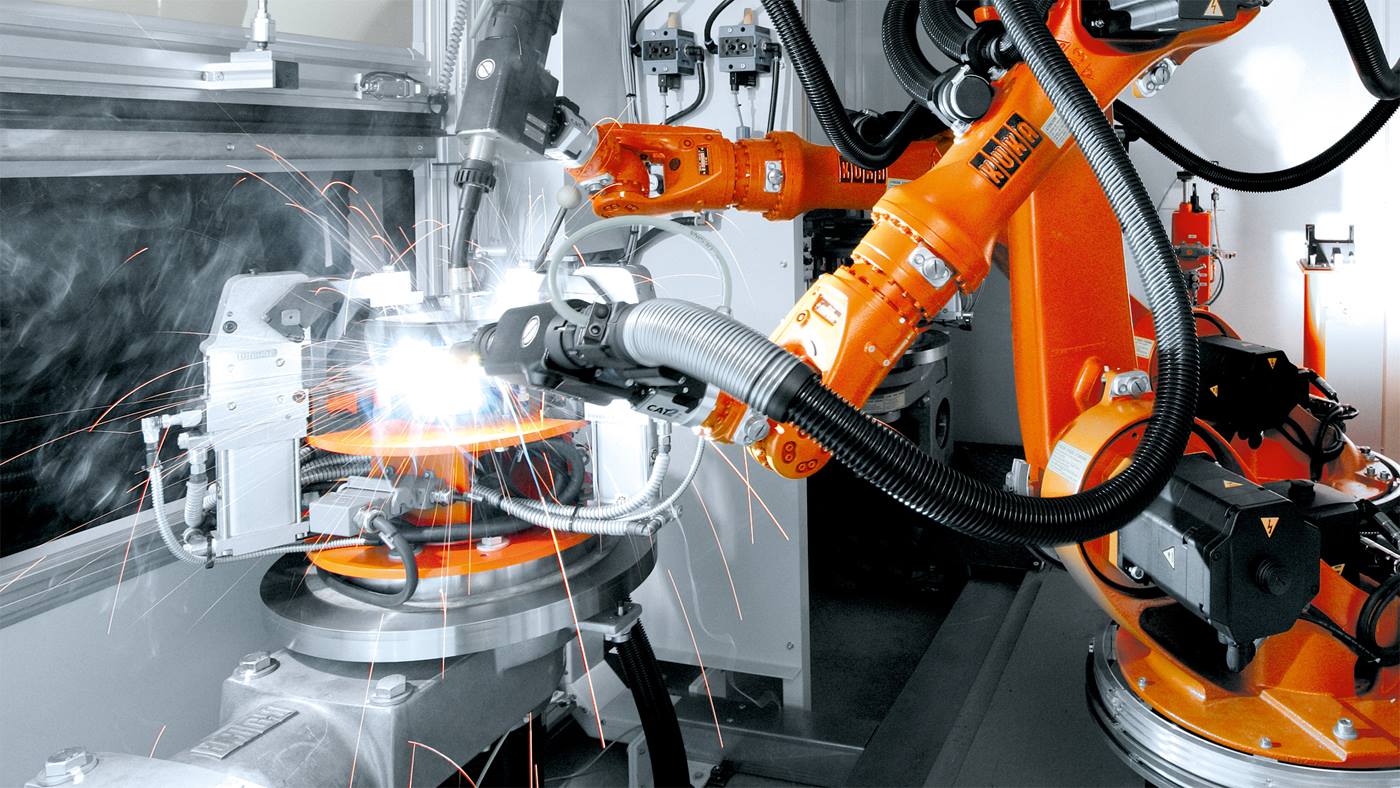

For more than 50 years, E&E Manufacturing has been stamping out a variety of heavy-gauge fasteners and components for a global automaker customer base. With its Plymouth, Michigan location in operation since 1962 and an Athens, Tennessee, facility commissioned in 2004, the Tier 1 manufacturer opened a new plant in Decatur, Tennessee, in March 2024 to expand its robotic welding capabilities.