Every Second Counts with Automotive Tier 1 Supplier

The need for speed is still alive and well in the automotive Tier 1 supplier world. We witnessed this firsthand at Sodecia’s Global Technology and Automation Center (GTAC) facility in London, Ontario, Canada.

“We then determine how many robots are needed to do all the processes on the part in that amount of time,” explained Remillard. “How many will it take to do the welding and apply all the sealant, how many parts an operator can load in that amount of time and so on. We will engineer a process with the minimum number of robots, operating stations and other systems and run the automation as fast as needed to meet the target cycle time.

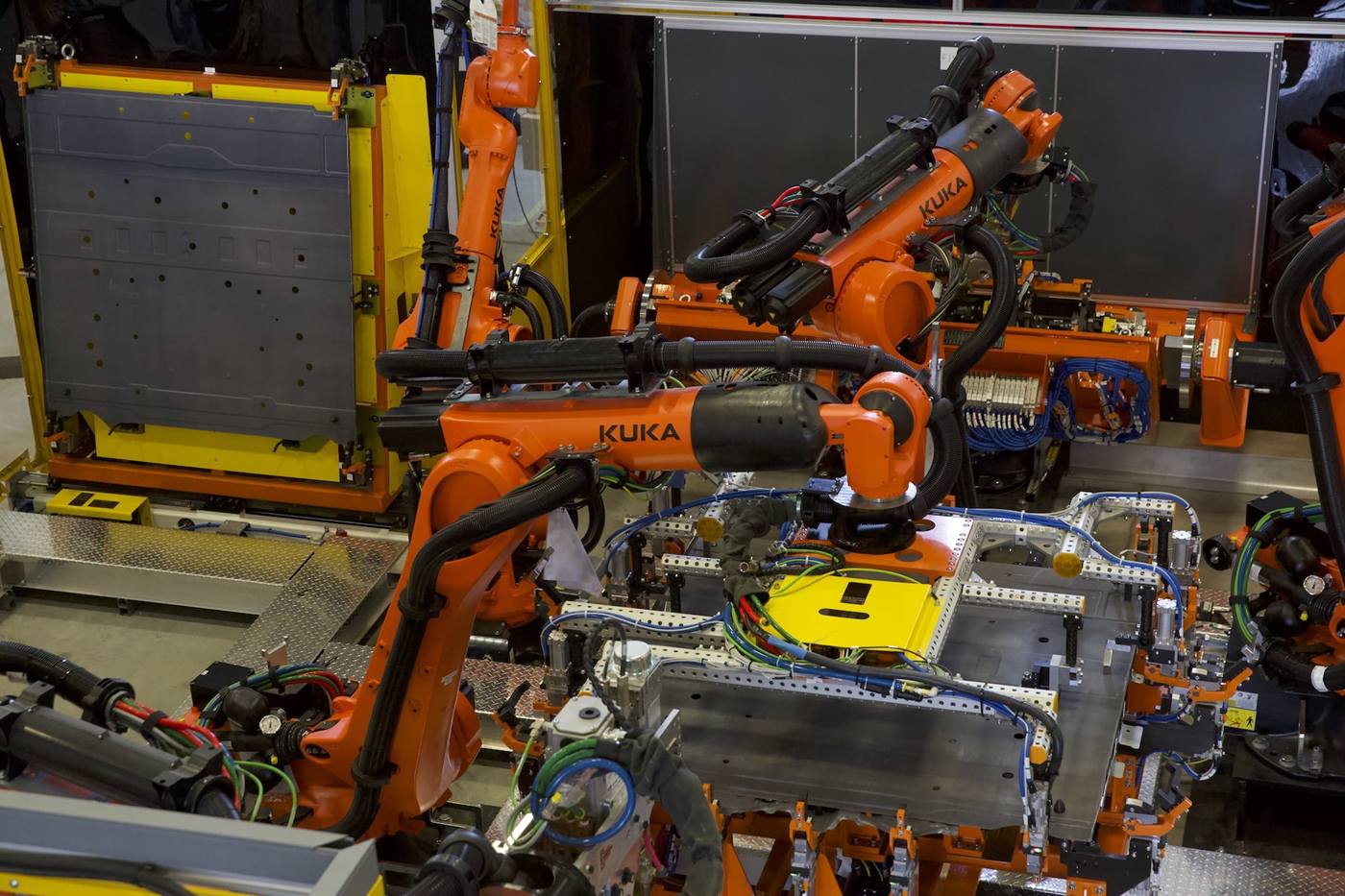

GTAC’s current automotive floor pans project is quite large, divided into four stages and six main cells. Each cell uses eight robots, two unload robot cells, plus nine robots to perform sub assembly and other miscellaneous tasks. The most recent stage of the project involves two main cells and eight robots to do spot welding, sealant and stud welding, and each pan requires about 700 welds.

All the robots used in the floor pan project are from KUKA Robotics.

It’s the way they construct their robots... They’re like tanks – strong, stable, reliable, and they can accelerate and decelerate faster than any other robot I’ve seen.

KUKA’s control system was another factor in Remillard’s robot decision-making process.

“For us at GTAC, and because we are starting out and basically still doing a lot of internal work, our goal at the end of the day is not just to develop a process that works, but to make our customers better, more efficient and more cost effective,” said Remillard. “Whether that’s Sodecia or a new outside customer, they come to us with a need to make a part, and while some integrators will offer the bare minimum when it comes to a process to produce that part, we aren’t like that."

GTAC has set standards across the board and applies all that we’ve learned from past projects. Plus, we don’t skimp or compromise on the equipment we use, and for us, the standard is now KUKA.