What robot technology can achieve in meat processing

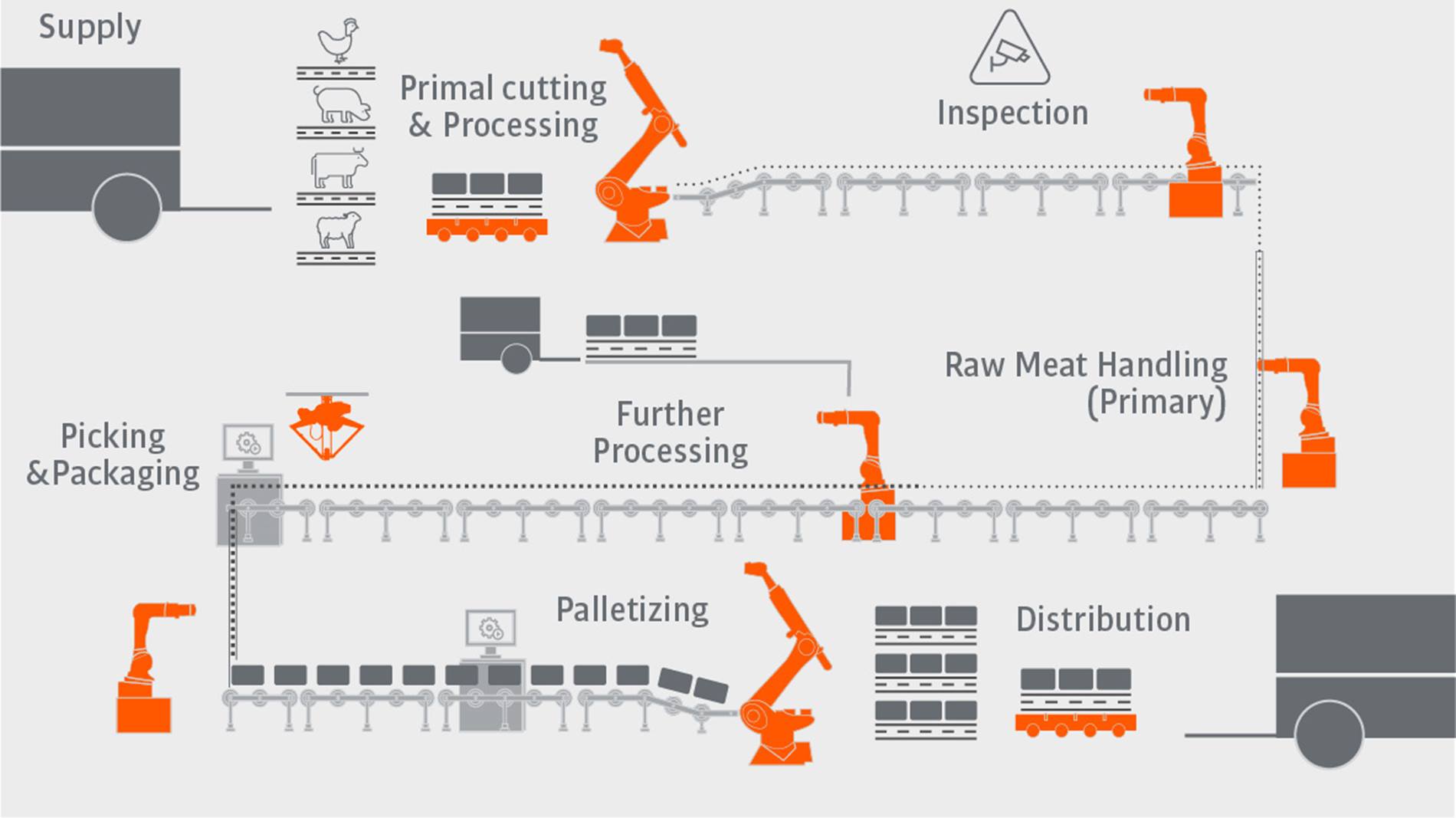

The demands on the meat processing industry are increasing every year. Automation systems that cover the entire process chain in meat processing are a decisive factor when it comes to high food quality and hygiene standards, as well as a small CO2 footprint. This includes tasks such as cutting meat of all animal species, stamping, inspections, further processing steps such as marinating, and packaging and palletizing.

Excellence in development and service

High food quality requirements, rising production prices, a growing shortage of skilled workers – there are many challenges for meat processors and the industry is continuously having to respond to them in new ways. For this reason, rely on an automation partner with decades of experience in the food industry.

Our customers benefit from high productivity, low costs and increased food safety as a result of reproducible processes. Our worldwide presence and 24/7 service guarantee reliable support for all questions, including on site.

Our portfolio along the process chain

Every automation system is centered on robotics. Their performance, precision and speed determine efficiency in meat processing. Our systems also bring decades of industrial expertise to the meat sector.

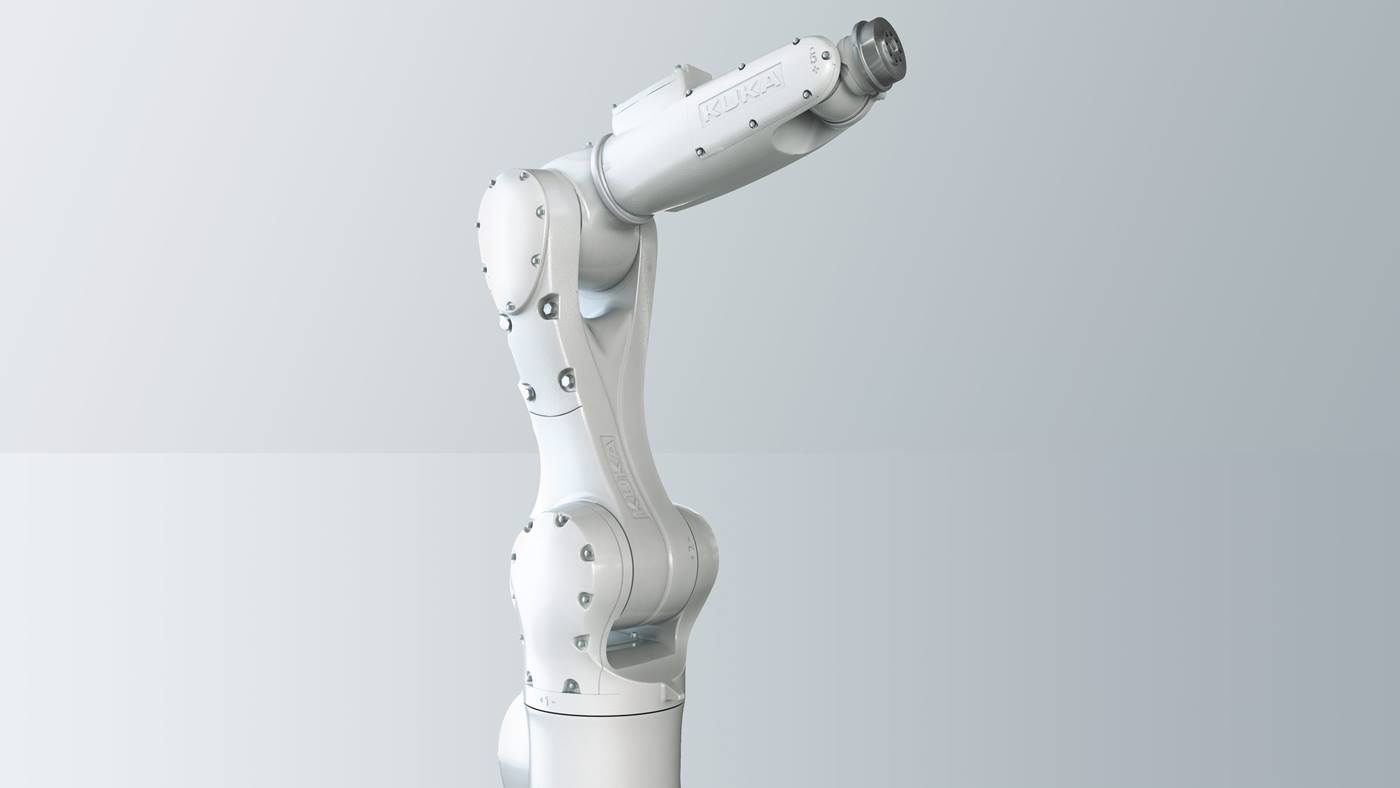

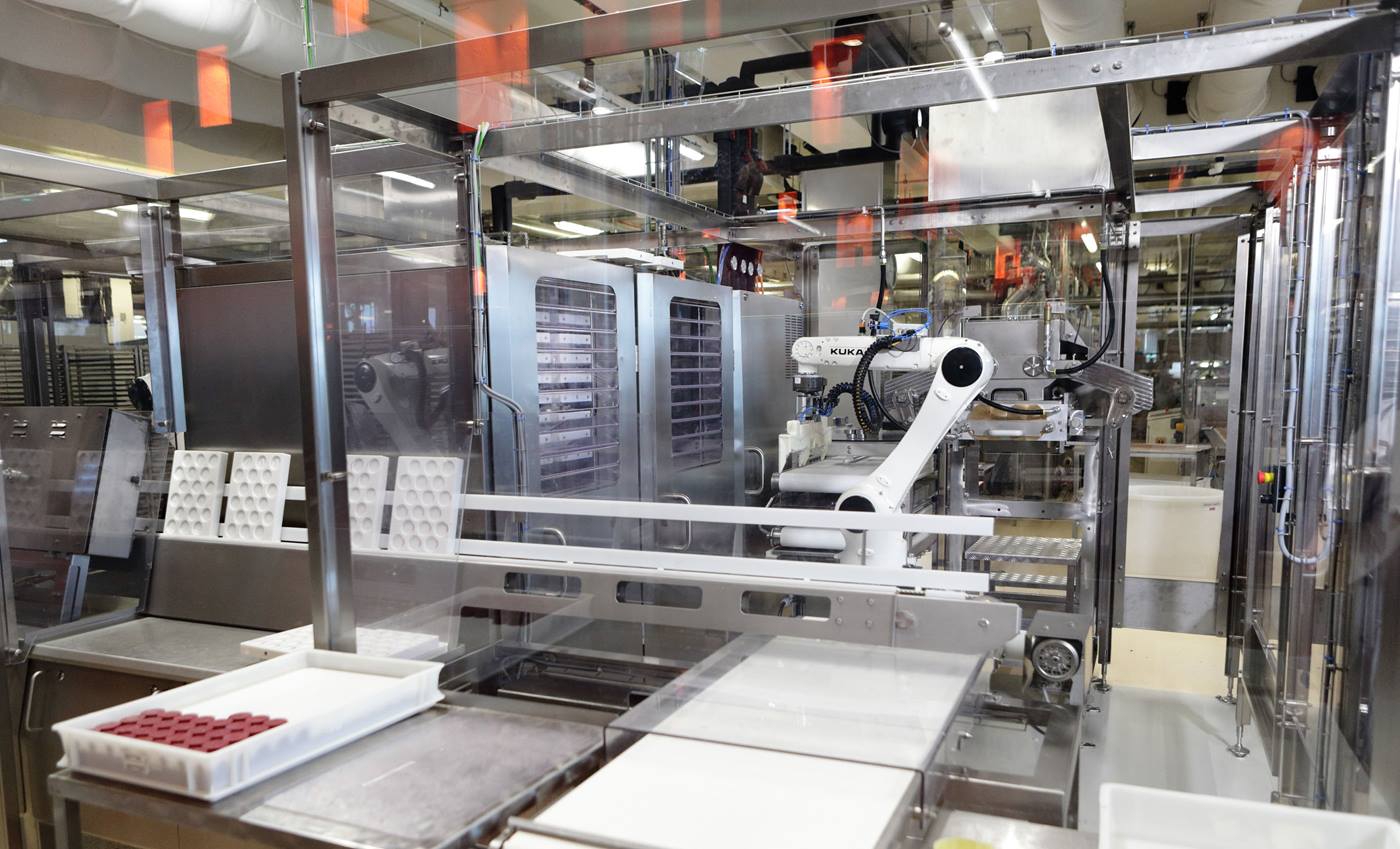

In this harsh environment, the robot technology primarily has to be able to withstand particular humidity, heat or cold, e.g. in cold storage rooms and damp rooms. All our products are designed for this purpose with a robust mechanical system and the necessary IP rating.

Our Hygienic Machines (HM) are ready for immediate use with raw food. All other robots will be equipped with tailor-made protective covers.

Software technologies for meat processing

With our software options for the entire value chain in the meat industry, you can successfully control your applications. Our holistically conceived solutions implement specialist know-how of new technologies, on which we are constantly building.