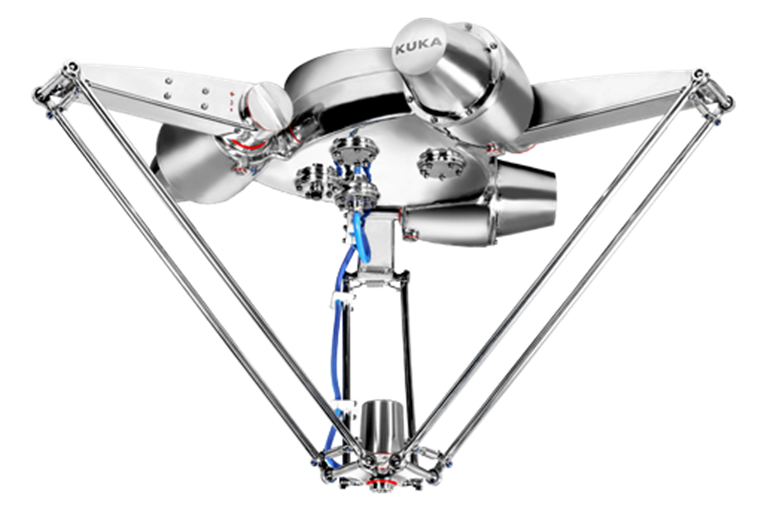

The delta robot: three-armed parallel robot

The delta robot is a high mounted apparatus with the motors fixed at the base and three pre-assembled linked arms below the robot, which allows high acceleration and a large range of motion, all while being precise in execution of pick and other applications.

Hygiene at a high level.

KUKA DELTA robots are designed for use in highly sensitive conditions.

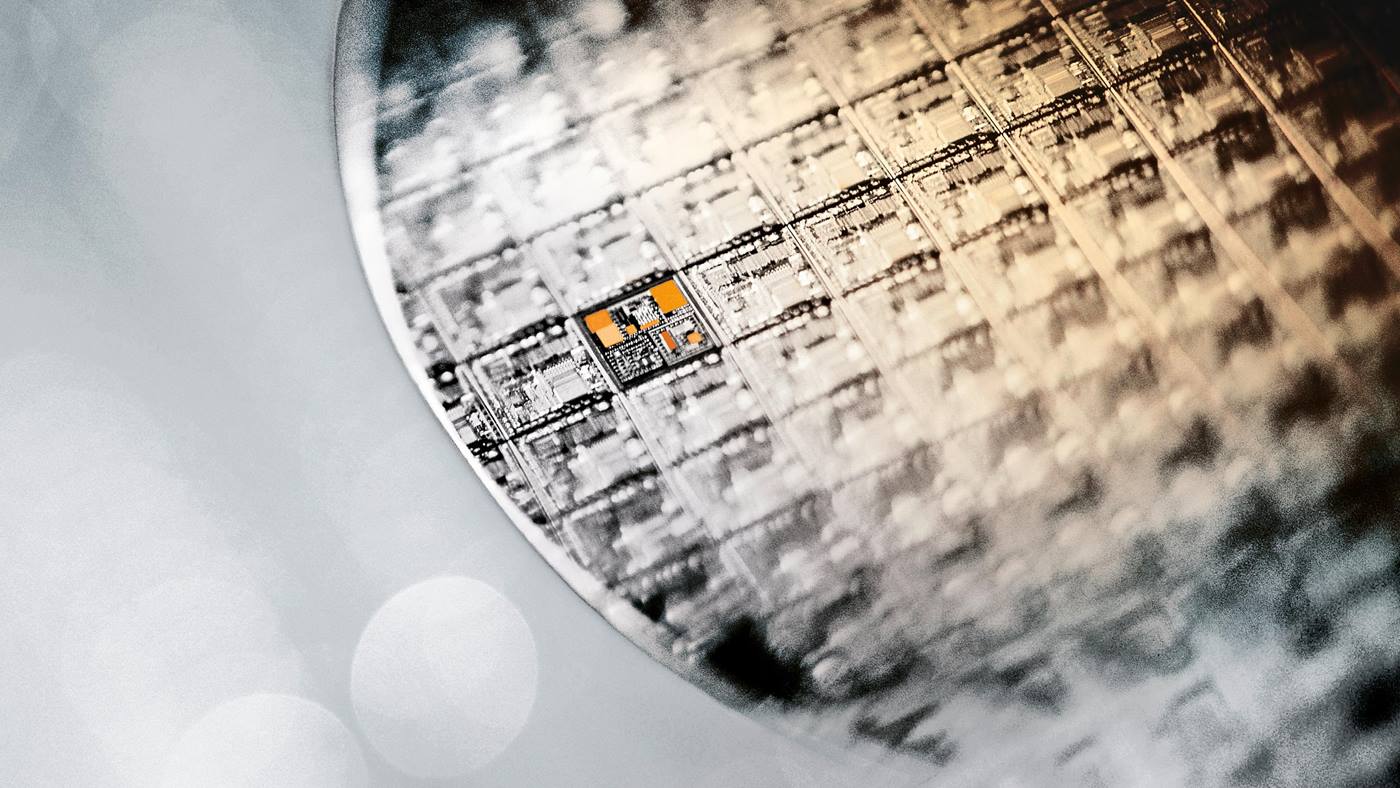

Thanks to its stainless steel body, the DELTA robot is ideally equipped for hygienically sensitive areas, such as direct contact with food, medicines or electronic components.

Industrial robots are an essential element within today's factory environment, even more so within the factory of the future. The demand for industrial robots stems from the need for versatile, intelligent machines able to perform repetitive tasks cost effectively with a wide range of motion whilst maintaining quality consistencies and reduced cycle time. The delta robot satisfies these demands.

The robot's corrosion-resistant stainless steel shell is designed according to German LFGB and US FDA food standards and also meets European CE certification and German TÜV safety function certification. The robot is protected against dust and moisture according to IP 67 protection class and can therefore be cleaned under high pressure and with alkaline or acidic cleaning agents.

Software and hardware as a perfect complement for DELTA robots

With flexible DELTA robots and matching hardware and software, KUKA offers cost-effective solutions for automated picking and packing. The robots can also be seamlessly integrated into all known KUKA software packages - from KUKA.PickControl to KUKA.VisionTech. With a special software, up to 10 robots can simultaneously perform the same or even completely different tasks. Requirements such as material sorting, packaging, palletizing and assembly are only a fraction of the possibilities offered by KR DELTA robots.

Application package featuring the KUKA DELTA robot arm for picking and packing in the food industry

In the Hygienic Machine variant, the KR DELTA robot achieves maximum hygiene levels. Perfect robotic solution for the primary packaging of food and medicines.

The Hygienic Machines and Hygienic Oil robotics with food-grade NSF H1 lubricants and optimized cleanability meet the high requirements of the primary and secondary sectors. Their hygienic design complies with EHEDG recommendations. Their Robotic arms are therefore versatile, from the automation of pick-and-place tasks, through final packaging, to sorting and packing.