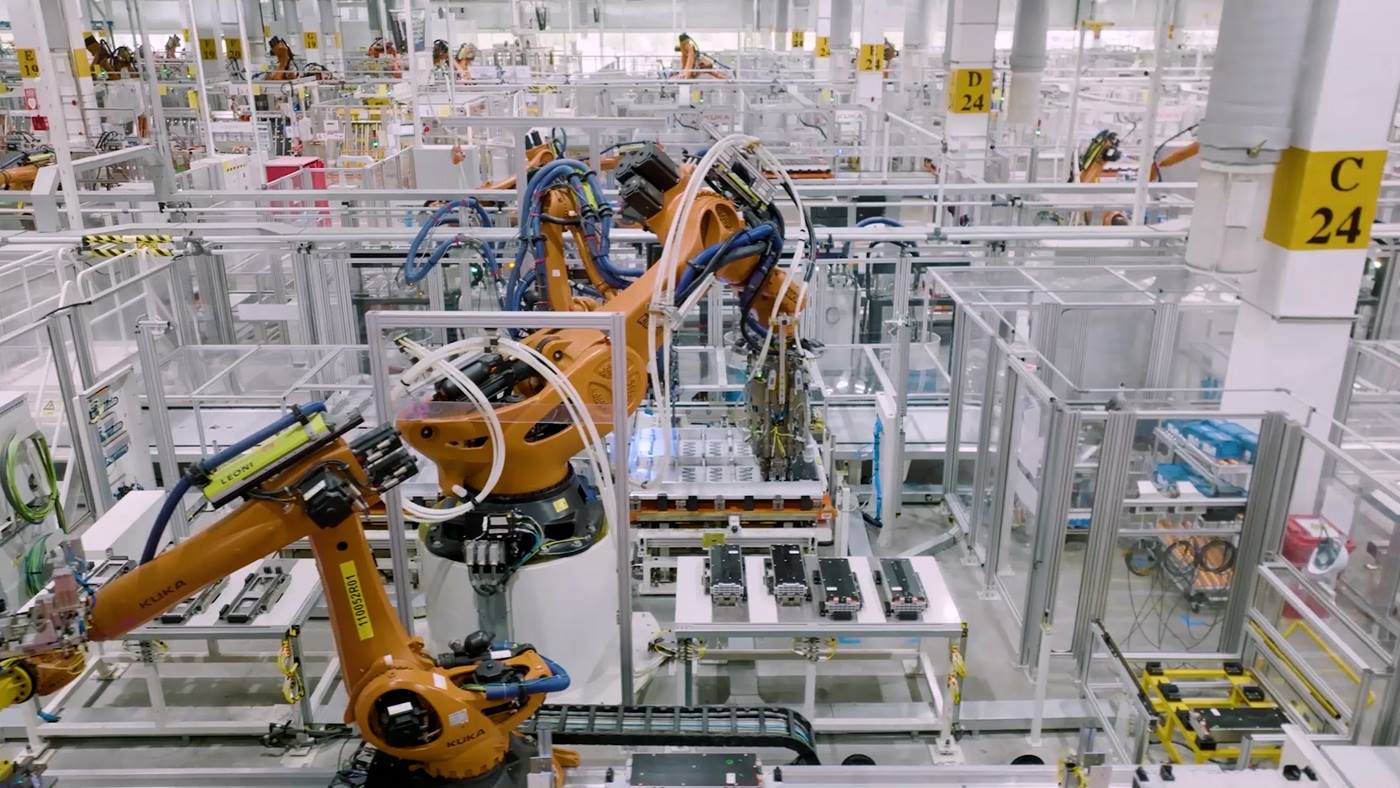

The new pace of palletizing.

KUKA palletizing robots offer an unrivaled variety of options.

Our robotic palletizers can handle items weighing from 10 to 1,500 kg and reach ranges of up to 3,900 mm. Whether complete pallet layers or individual packages – from bags and buckets to cartons or trays – they ensure fast, reliable, and flexible automated processes in production, packaging, and logistics. Built for durability, they perform flawlessly even under demanding conditions, from low temperatures to hygienically sensitive environments.

Palletizers at a glance – from compact to powerful

Palletizing with a collaborative robot – also possible without a fence

Optimize your processes with the

LBR iisy cobot palletizer – flexible, productive, and safe, without protective fencing. Its compact design, integrated sensors, and high speed enable seamless integration into existing manufacturing lines. The innovative operating system simplifies installation, configuration, and programming, allowing customized stacking, optimal space utilization, and increased productivity. Ideal for single or multiple conveyor belts, pallets, or shelves, it enhances efficiency and safety.

The cobot palletizer is equipped with a lifter and a specially developed vacuum gripper.

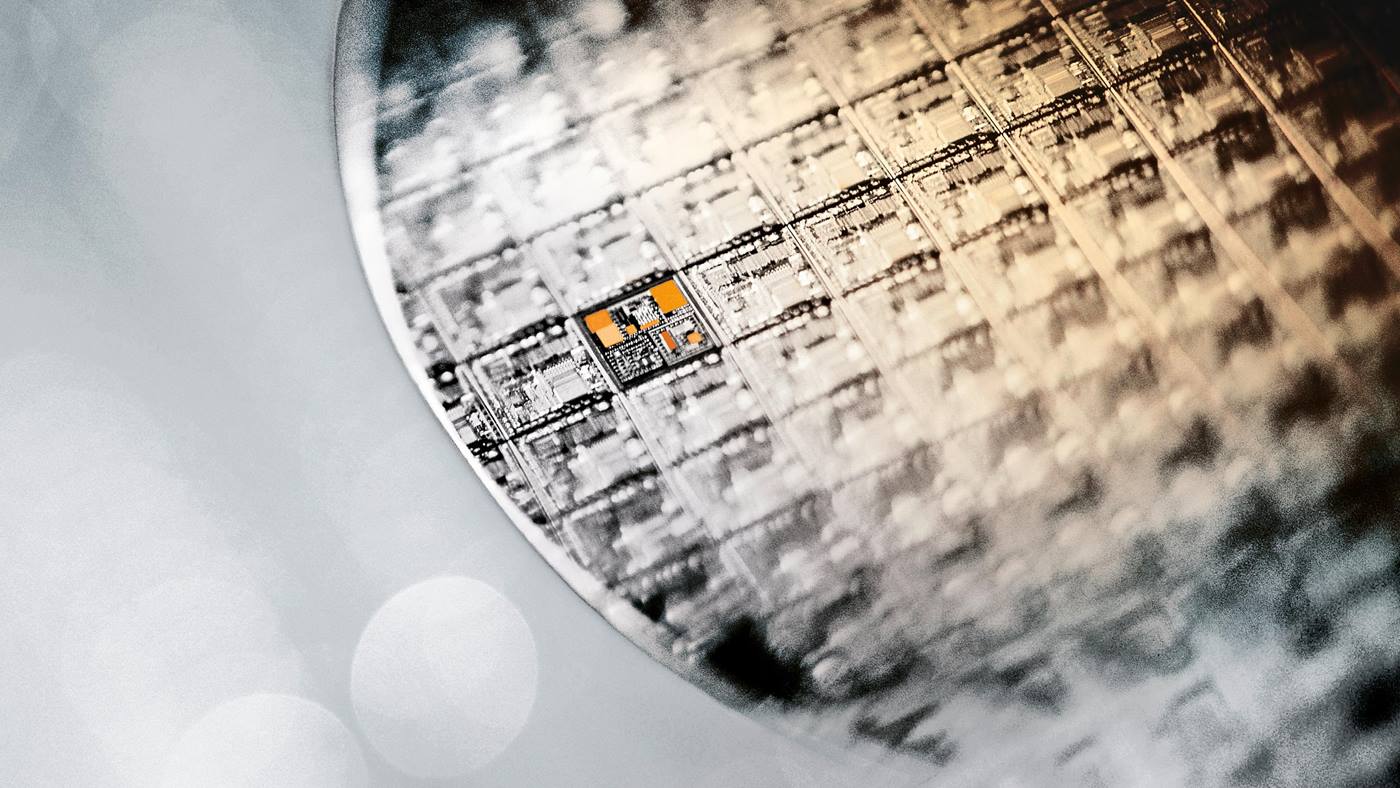

Greater efficiency in automated palletizing with smart software and AI assistance

Advanced software and AI take palletizers to the next level: precise product placement, drag‑and‑drop layer changes without coding, and smooth integration into existing lines. Simulations and real‑time monitoring cut errors, boost throughput, and make robots faster, more flexible, and cost‑effective — delivering significant added value for businesses