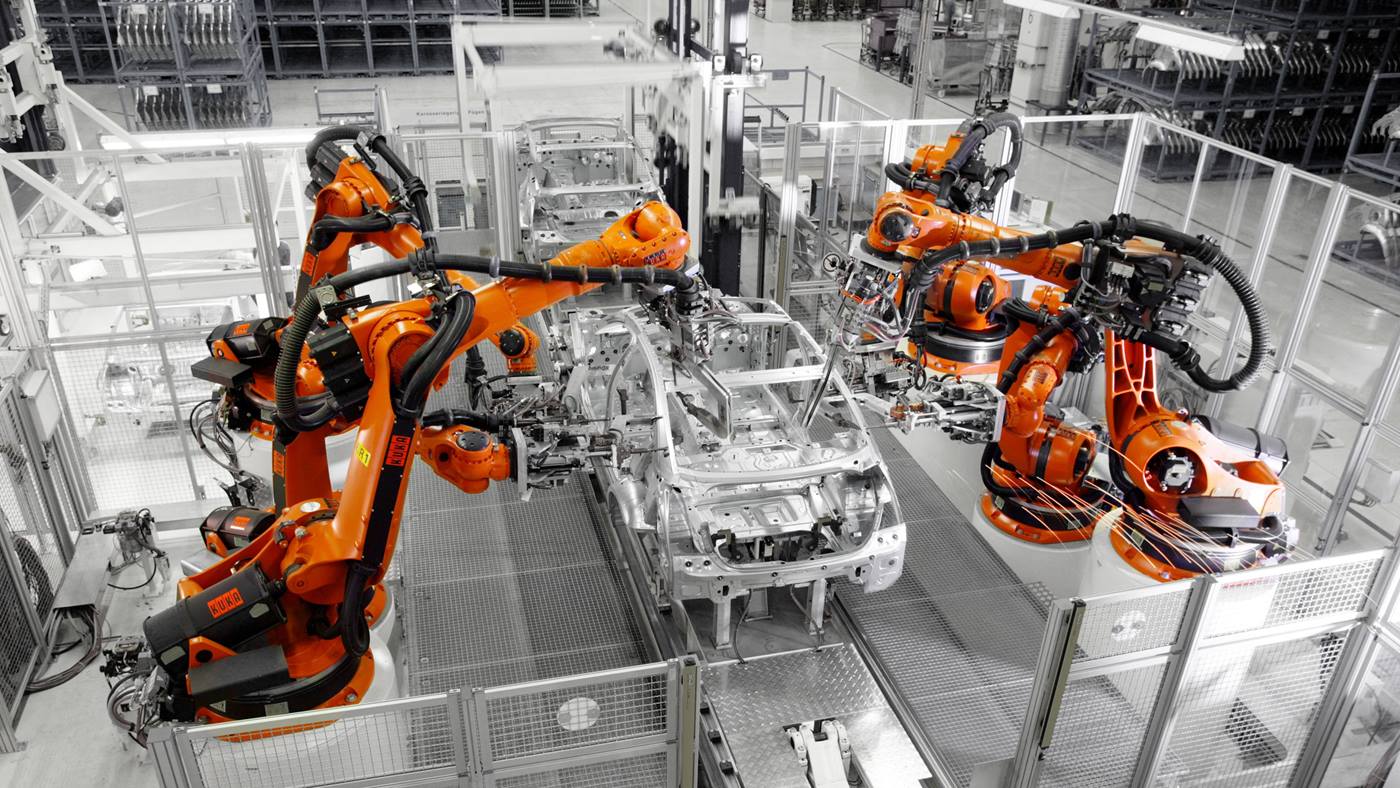

Automotive electronics production of the future

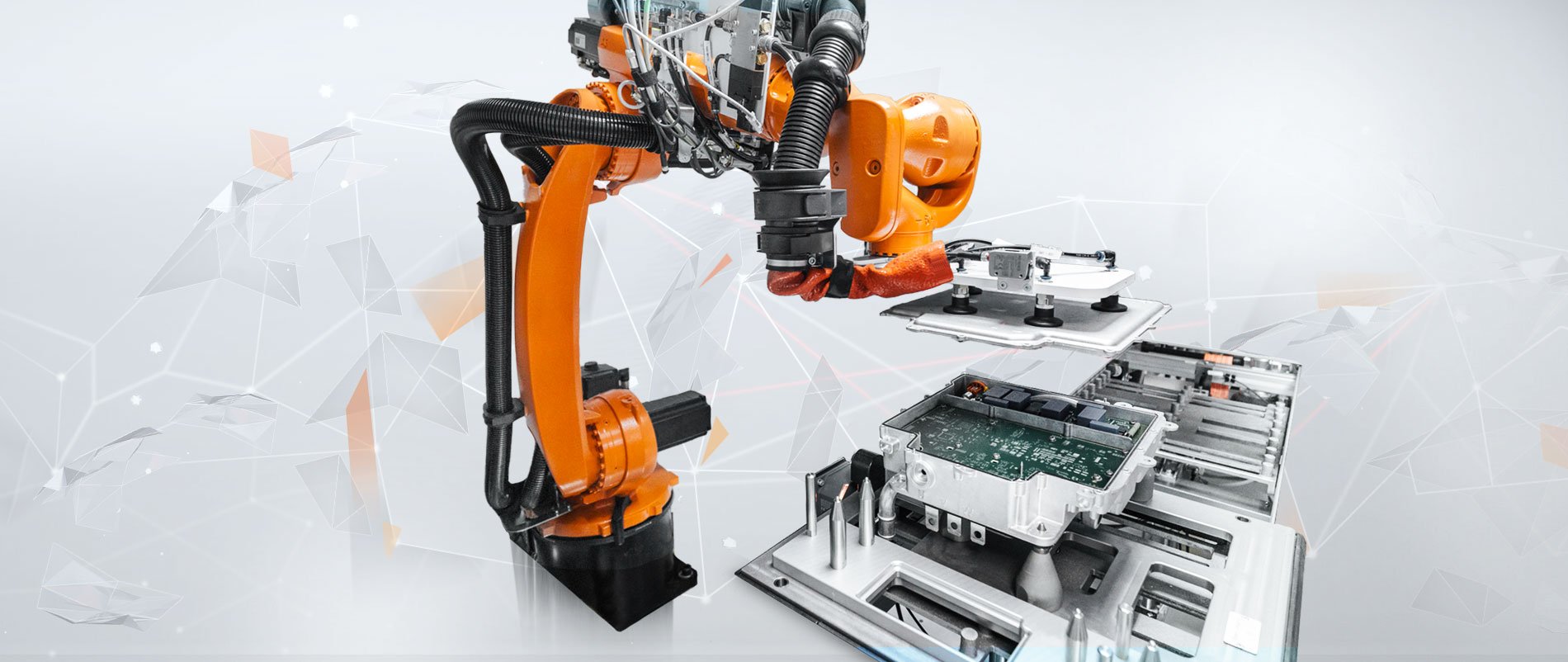

Perfect synergy between innovation and cost-effectiveness thanks to our specialized robotics portfolio and expert know-how

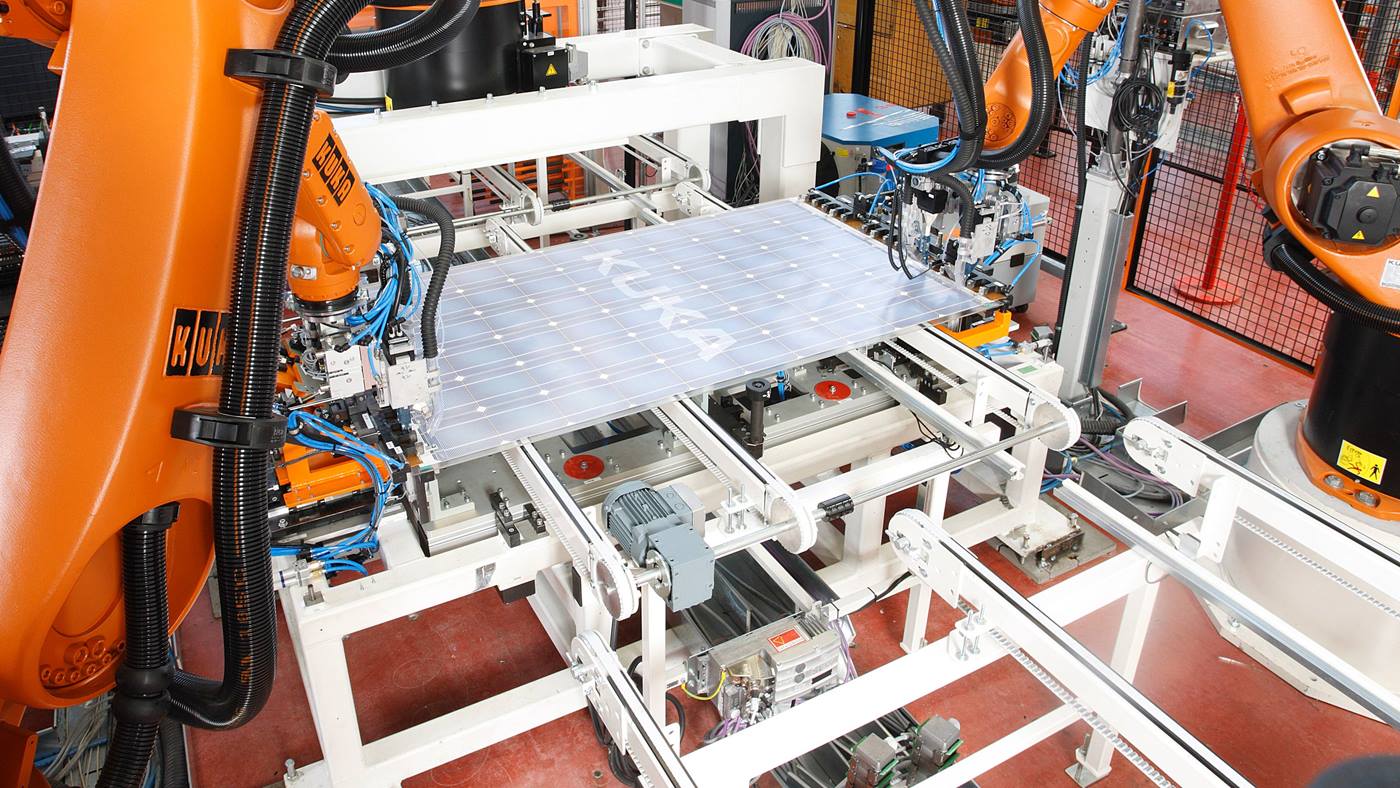

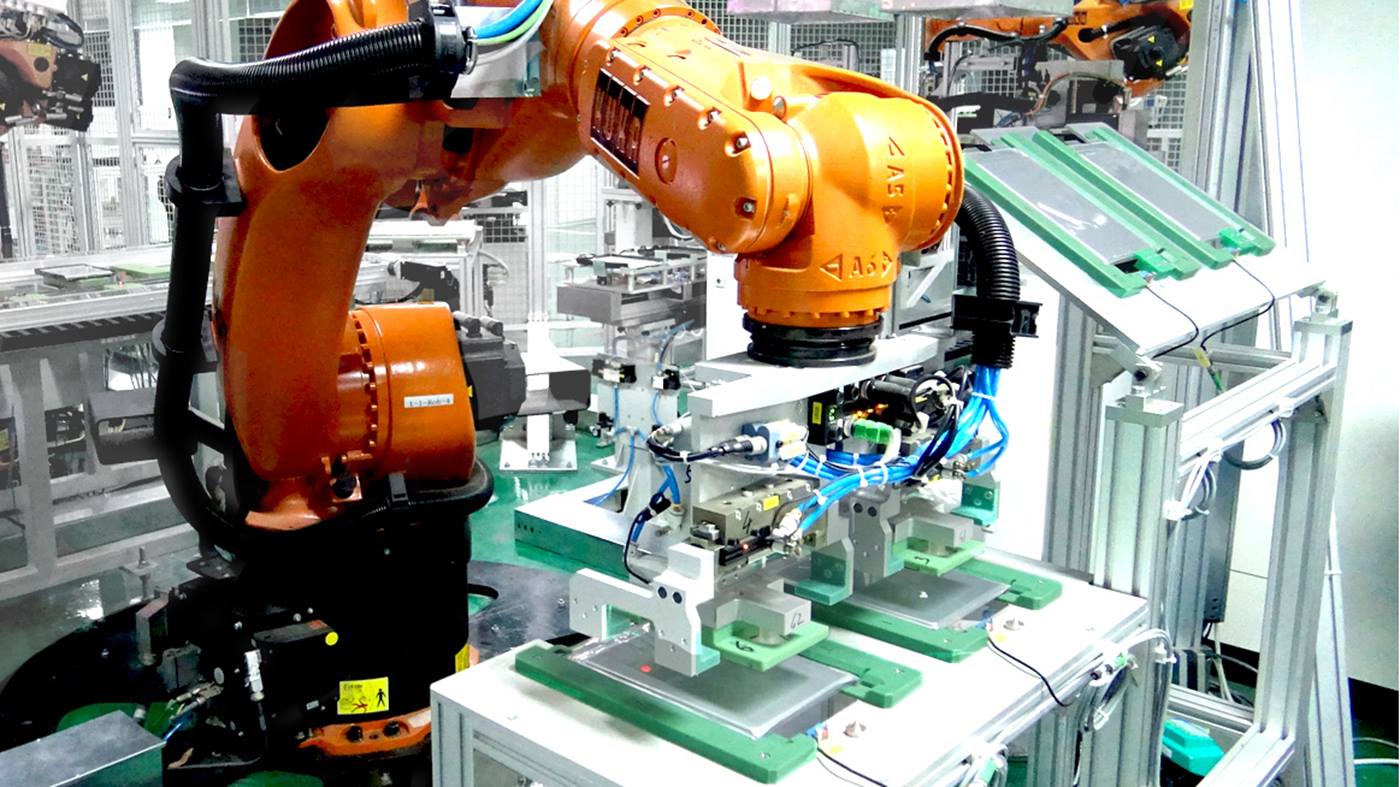

The automotive and electronics industries have more points of contact from one year to the next, with automotive electronics being the most automated sector in the electronics industry. KUKA has years of expertise in both sectors as well as the correspondingly certified robotics and software. To ensure that the high demands on the vehicle electronics components are met, such as temperature resistance, long service life and extreme robustness against vibrations and shocks, automated production is indispensable. We offer customers complete system solutions, from the concept and implementation through to maintenance.

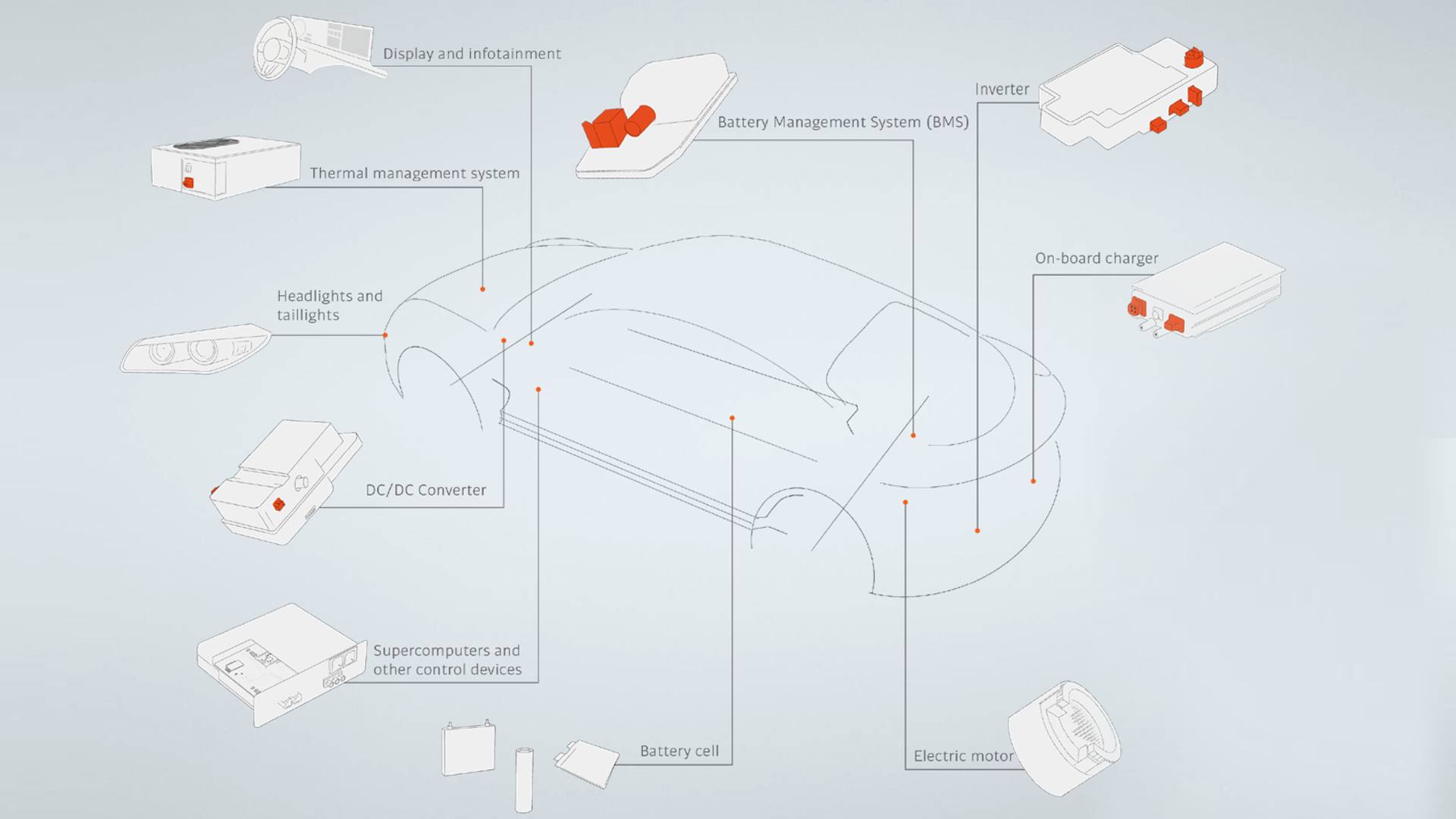

Technological progress for the manufacture of modern vehicles: solutions and products from KUKA

In the interactive graphic, discover the successful use of our robots and cobots in vehicle electronics in order to maximize manufacturing capacities and make production more efficient and reliable. We rely not only on high-quality machines, but also on environmentally friendly and sustainable automation solutions:

-

Thermal management system

Extreme temperatures have a negative impact on e-mobile batteries, cause rapid discharge and shorten service life. Efficient thermal management is of decisive importance for protection. Precise production of the systems prevents failures.

| Industrial robot | applications |

| | - Adhesive bonding

- Plasma and cleaning process

- Pick & place

|

-

Display and infotainment

On-board electronics systems improve functional safety for humans and comfort when traveling. Manufacturers have to respond quickly to changing trends. Robots are indispensable in the manufacture of these components, as they can be retaught in a very short time and ensure the long-term success of the manufacturers.

| Industrial robot | applications |

| | - Assembly

- Plasma and cleaning process

- Adhesive bonding

- Pick & place

|

-

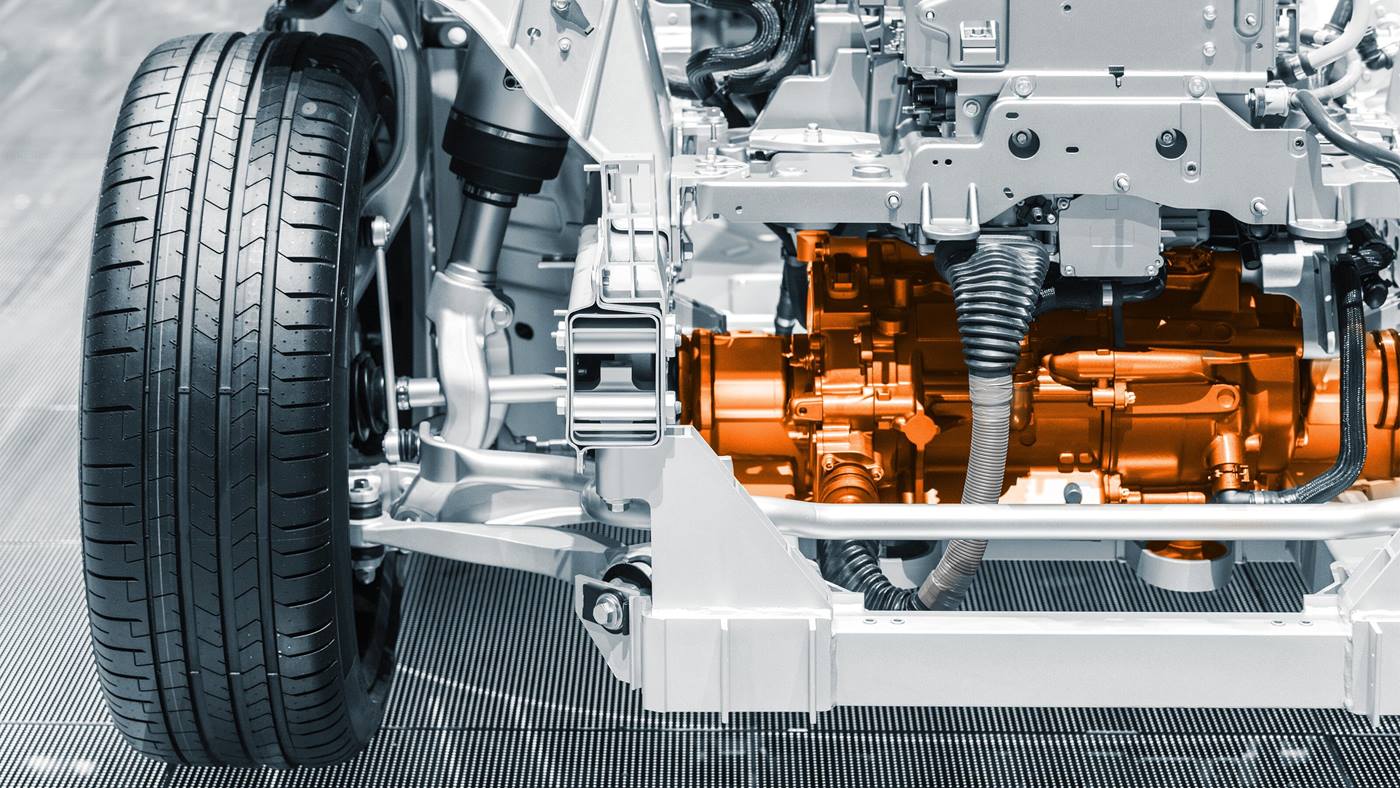

Electric motor

The use of robots in production offers flexibility in the continuous development of electric motors. ESD-protected robots enable reliable and flexible production. With the KUKA RoboTeam software, multiple machines are used and coordinated efficiently in assembly.

| Industrial robot | applications |

| | - Screw fastening

- Adhesive bonding

- Assembly

- Marking / needle embossing

- Handling

- End-of-line inspection

|

-

Inverters

The inverter converts direct current into alternating current for the vehicle motor and can also convert AC to DC to charge the battery. Robots manufacture the complex inverters with very short cycle times and perform quality inspection using vision systems.

| Industrial robot | applications |

| | - Adhesive bonding

- Plasma and cleaning process

- Pick & place

- End-of-line tests

|

-

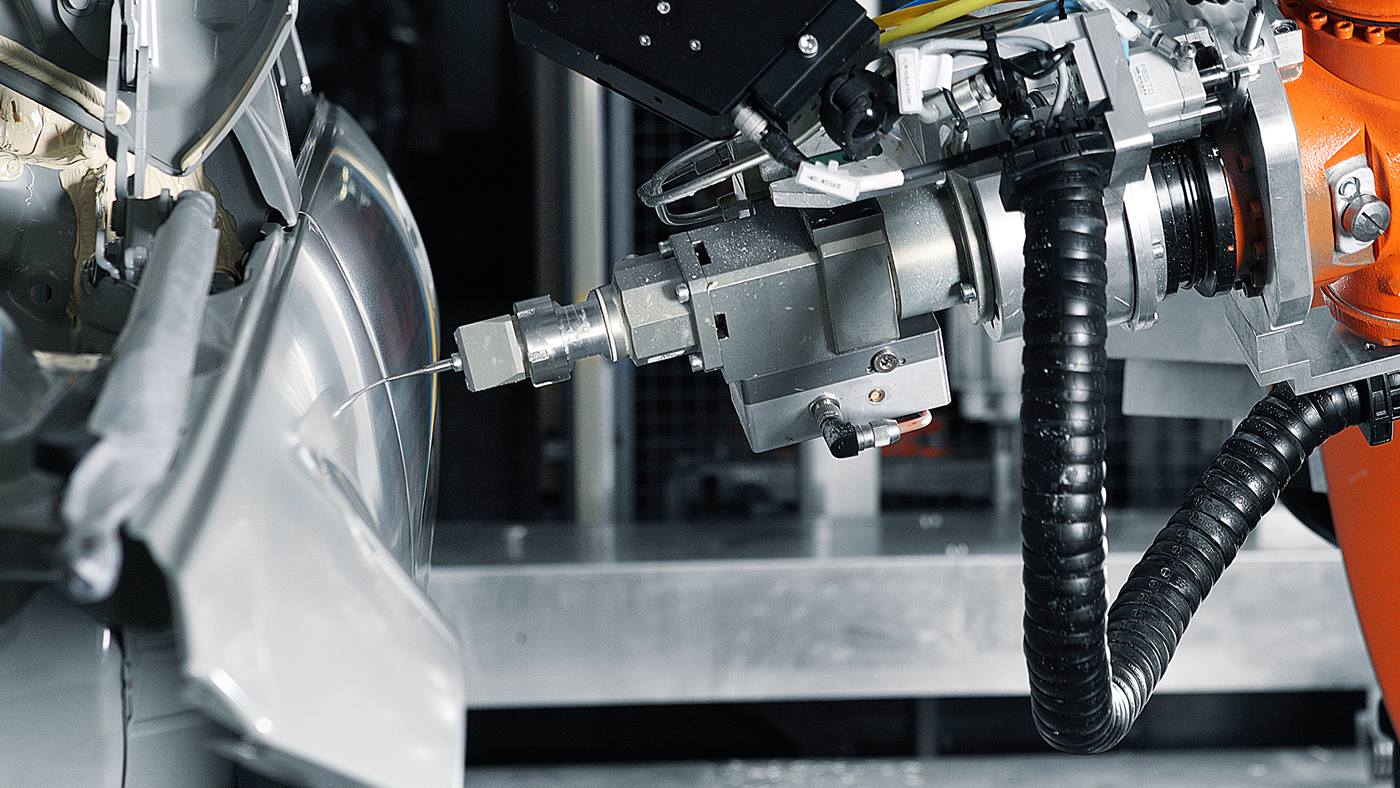

Headlights and rear lights

Vehicle lighting must be energy-efficient and durable. Robots have been supporting production for many years and ensure that every headlight and every rear light is produced absolutely waterproof and clean. And at high speed, with precisely calculable production costs.

| Industrial robot | applications |

| | - Adhesive bonding

- Plasma and cleaning process

- Screw fastening

- Painting/coating

- Handling of non-rigid parts

- Insertion of connectors

- Pick & place

- Abrasion test

|

-

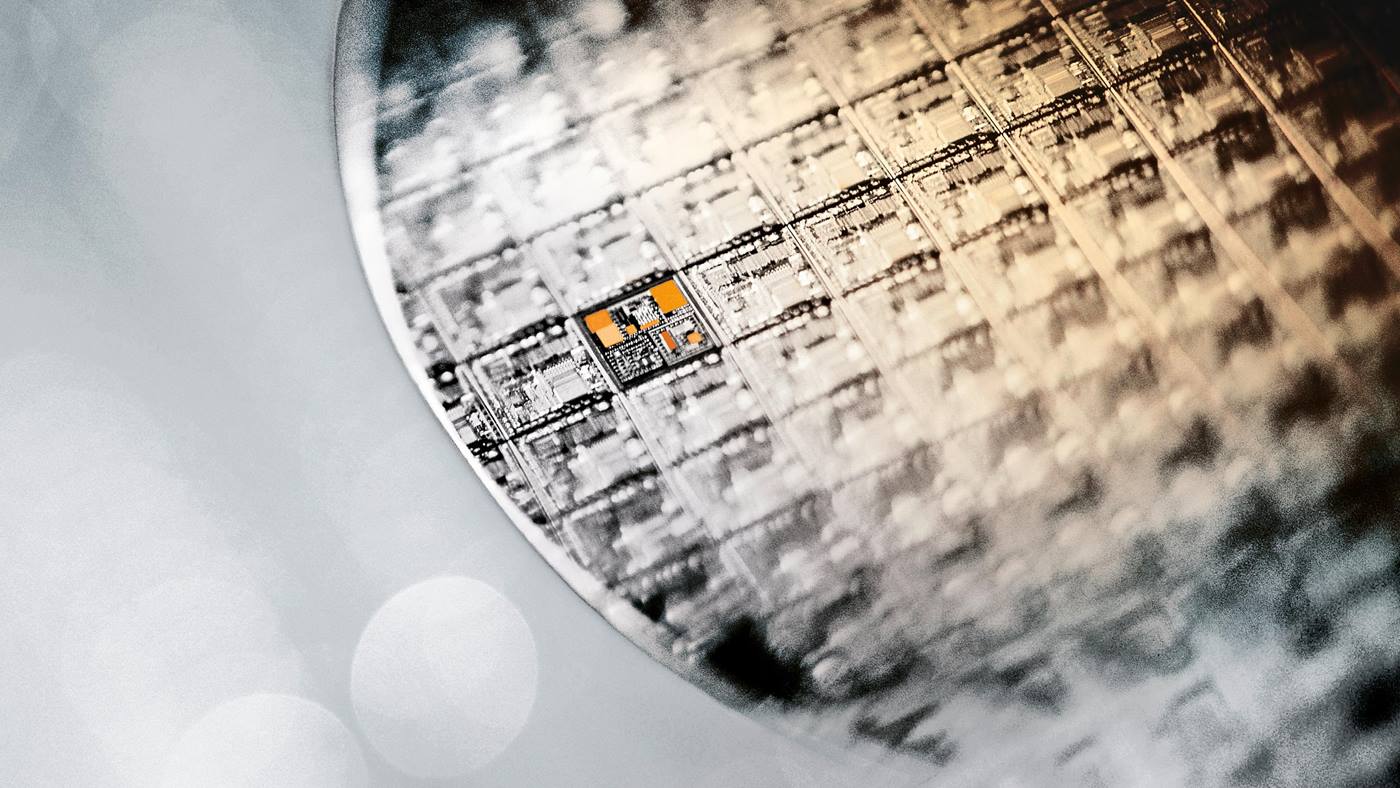

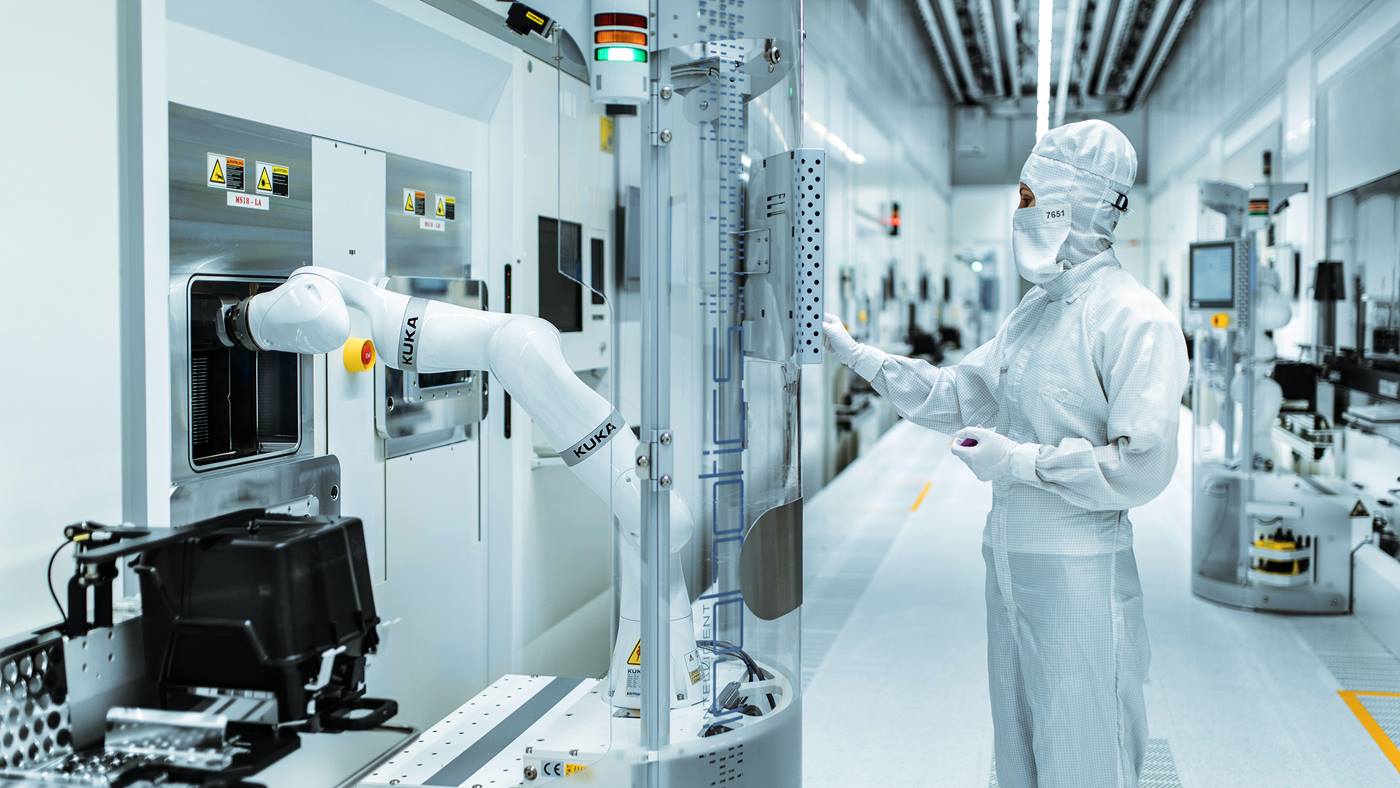

Supercomputers and other control units

In vehicle technology, high performance computers (HPCs) in electric cars enable fast Internet, regular safety updates and innovative driving functions. Reliable robots that work with great precision are used to manufacture these highly complex electronic devices.

| Industrial robot | applications |

| | - Assembly

- Pick & place

- Handling of non-rigid parts

- Insertion of connectors

- ICT test

|

-

On-board charger

Since on-board chargers are becoming ever more compact and with improved interference suppression options, many companies are increasingly relying on the use of robots. These enable fast adaptation to new requirements and make it easier for people to master tasks featuring small parts.

| Industrial robot | applications |

| | - Adhesive bonding

- Plasma and cleaning process

- Pick & place

|

-

Battery management system (BMS)

The BMS is essential for electric cars, as it controls, monitors and detects the charge of the drive battery. It also provides thermal management and balancing of the battery cells. Robots ensure quality in BMS production.

| Industrial robot | processes |

| | - Quality inspection

- Assembly

- Screw fastening

- Adhesive bonding

- Pick & place

|

-

DC/DC converters

EVs and HEVs have two separate DC networks connected by the DC/DC converter. Our automation technology keeps things flowing in the production of DC/DC converters.

| Industrial robot | processes |

| | - Adhesive bonding

- Plasma and cleaning process

- Pick & place

|

-

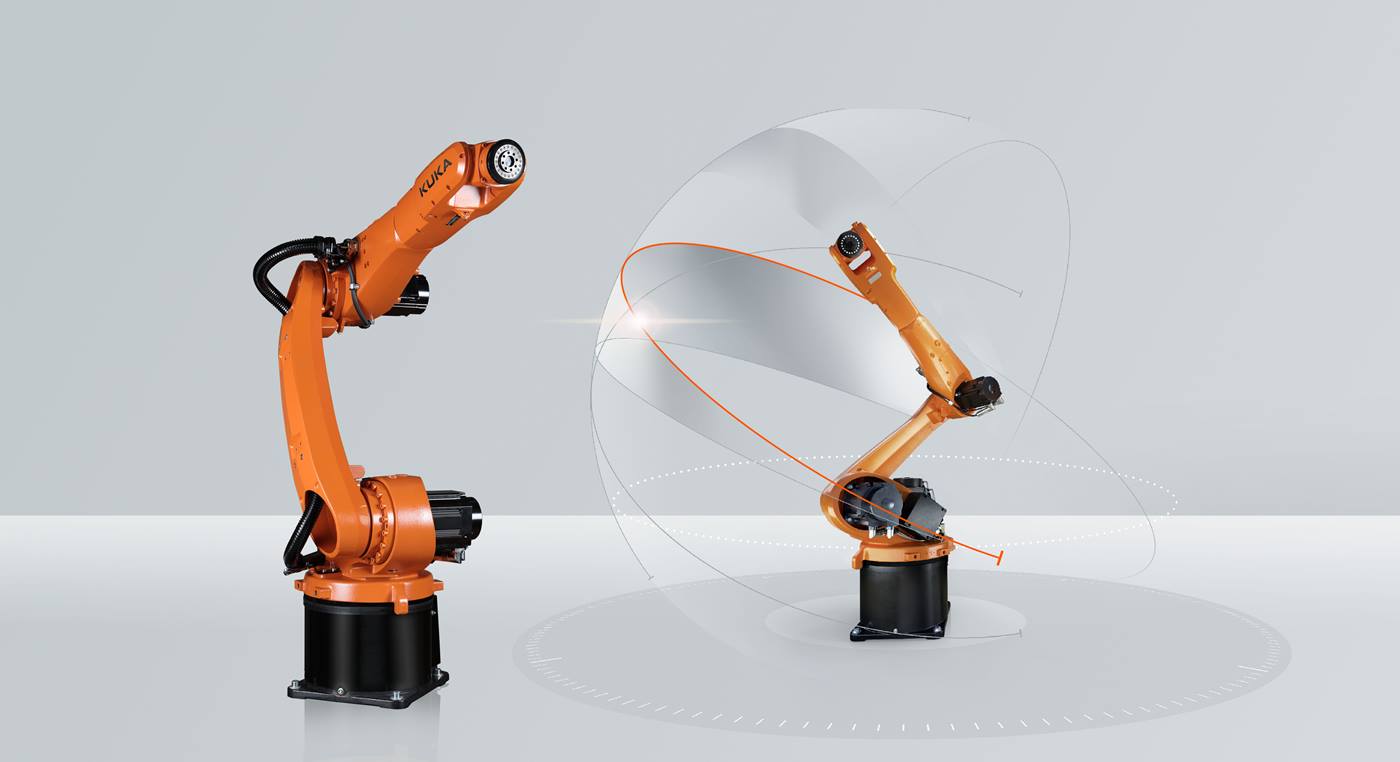

Wide range of application software: short start-up, high process reliability

→ KUKA.AppTech: Programming of KUKA robots in the application environment

→ KUKA.RobotSensorInterface: Interface for communication between the industrial robot and its sensor system

→ KUKA.Sim: Smart offline programming of robot applications in real time for maximum planning reliability and minimal costs

→ KUKA.PLC mxAutomation: Universal PLCopen-certified PLC interface

→ KUKA.SafeOperation: Safety-oriented monitoring of robot workspaces

→ KUKA.ForceTorqueControl: Programming of process forces and torques for a robot motion

→ KUKA.GripperSpotTech: Control of tools and grippers in the work environment

→ KUKA.VisionTech: 2D object recognition, code and OCR recognition as well as quality control

→ KUKA.RoboTeam: Cooperation of up to 4 machines in a team as well as synchronization of external axis kinematic systems such as workpiece positioners or robot linear axes

→ KUKA iiQoT: Industrial IoT platform for digitalized vehicle electronics production