What does deburring mean?

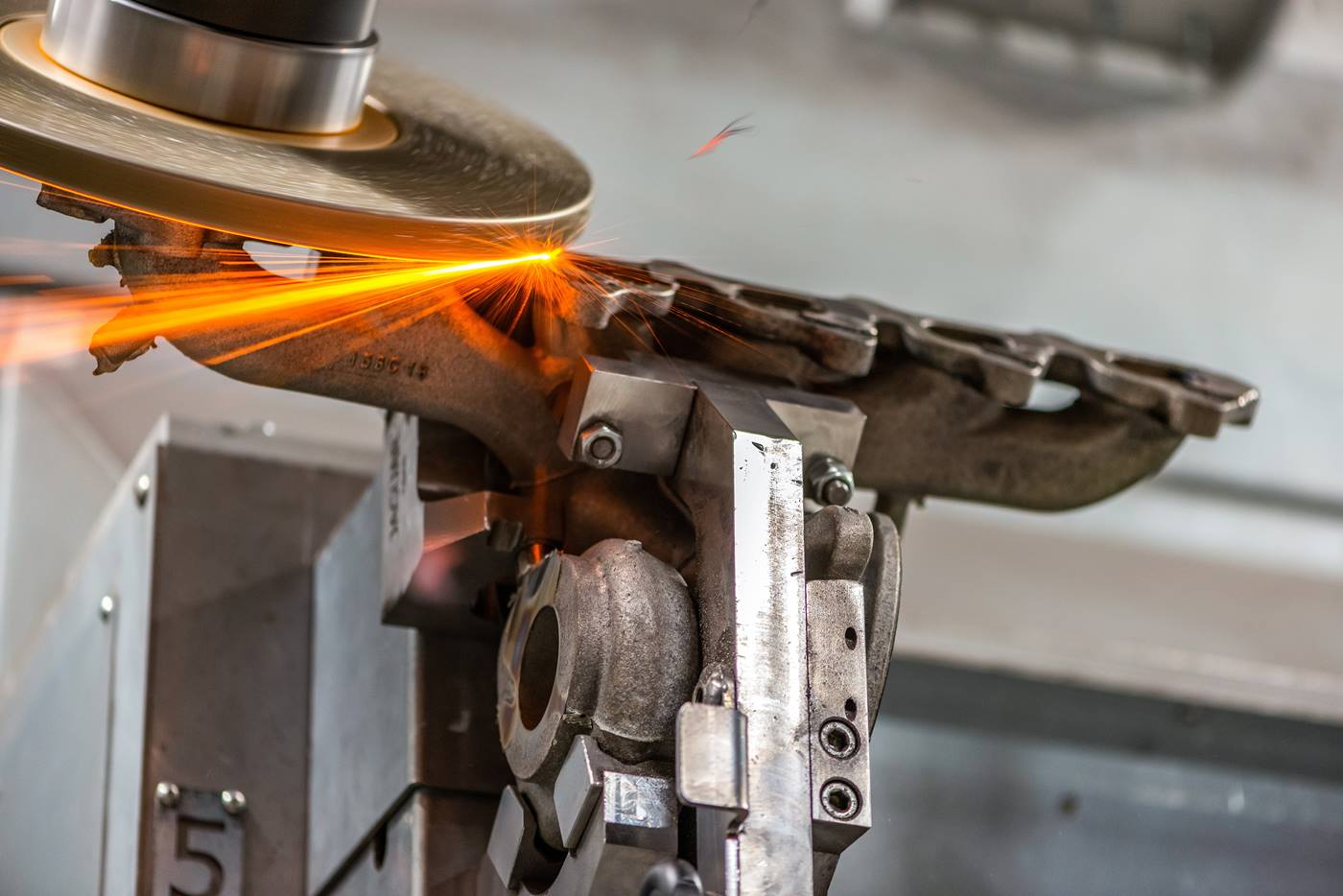

So-called flash or projections can form at edges during the various casting processes. These edges, which can be sharp, may not only impair the functioning of the end product but also increase the risk of injury.

For this reason, when manufacturing metal parts, these projections must be removed during the finishing process. This technology is referred to as trimming or deburring.