Learn about circular economy, digitalization, climate protection – and KUKA’s contribution

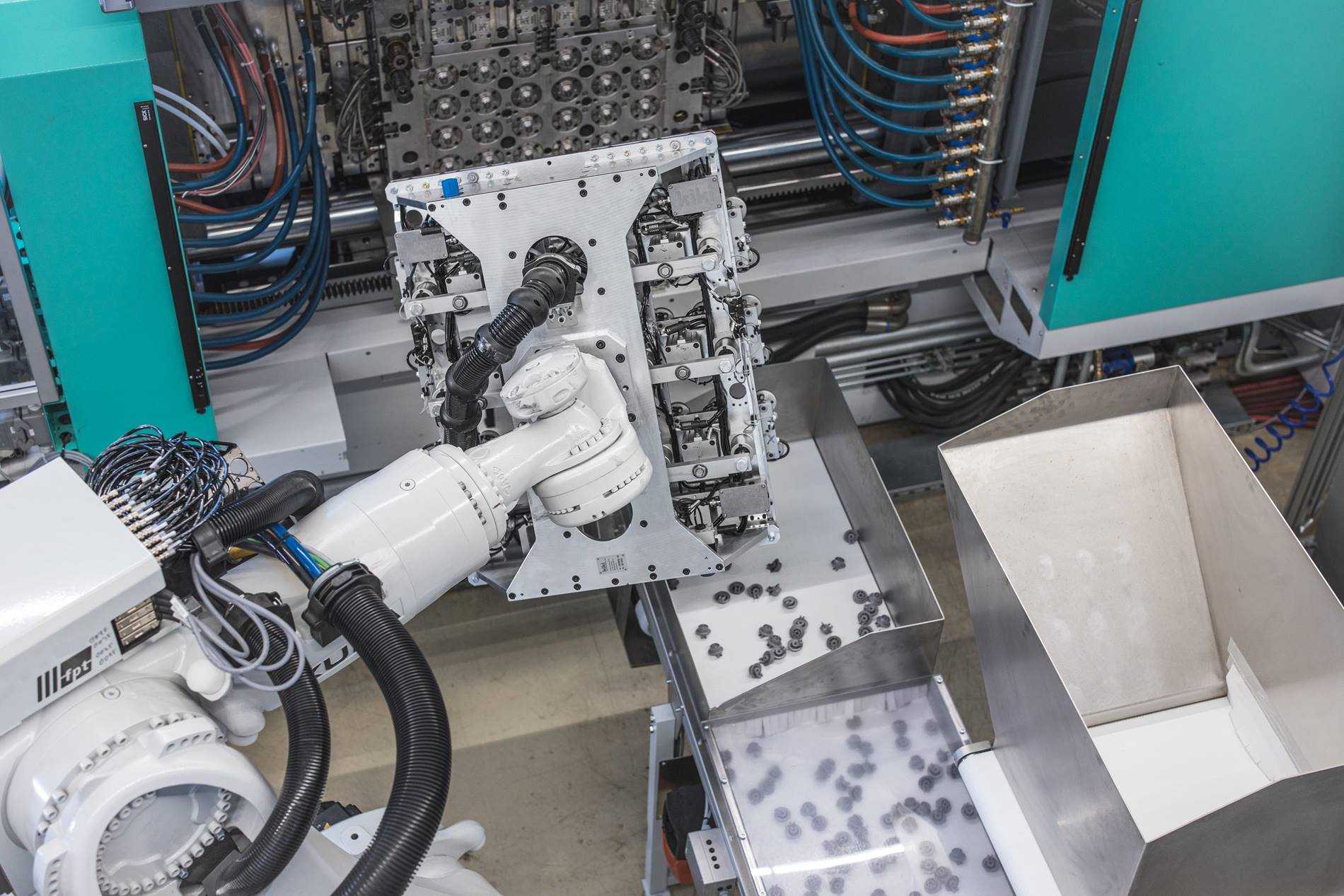

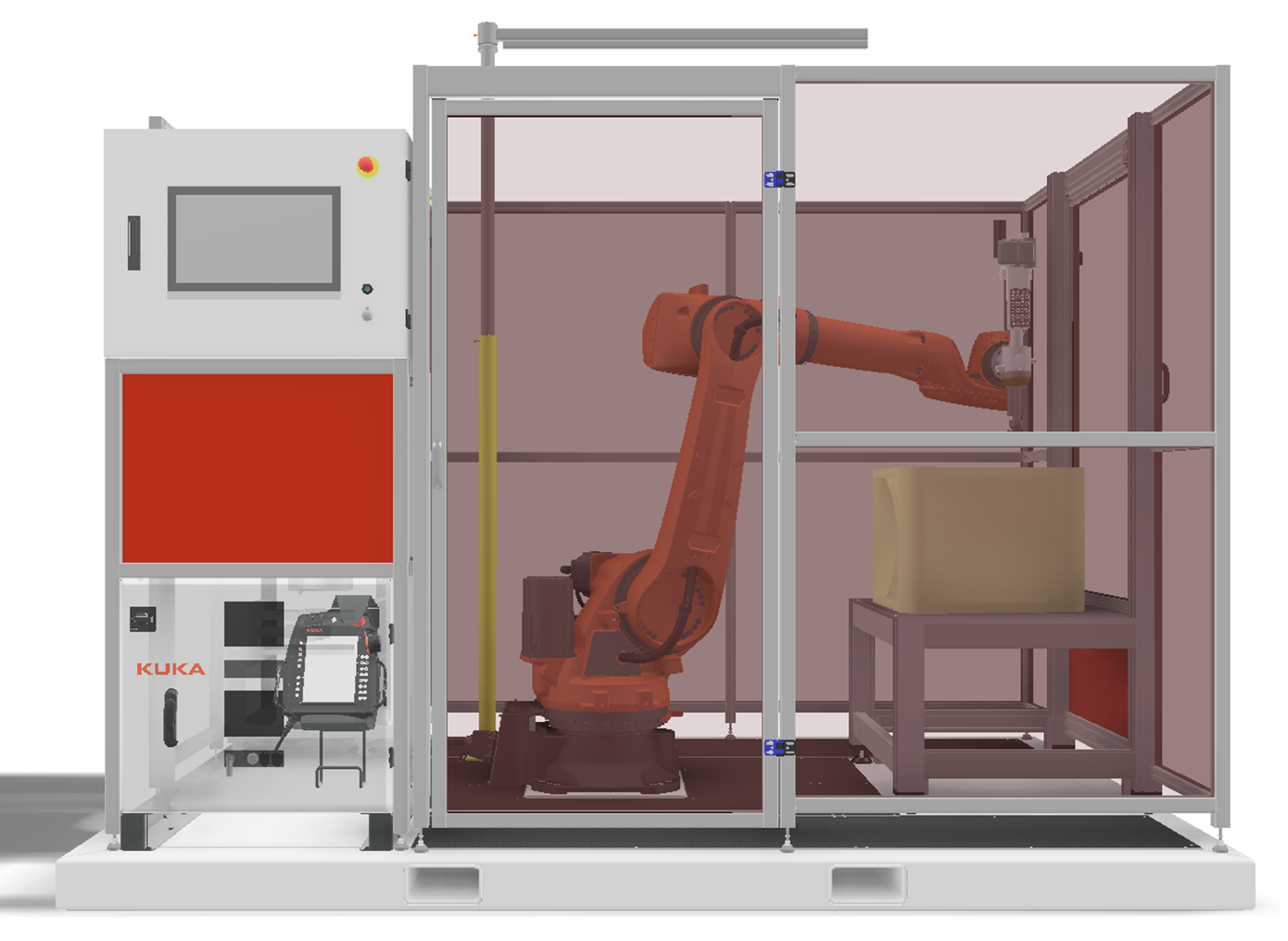

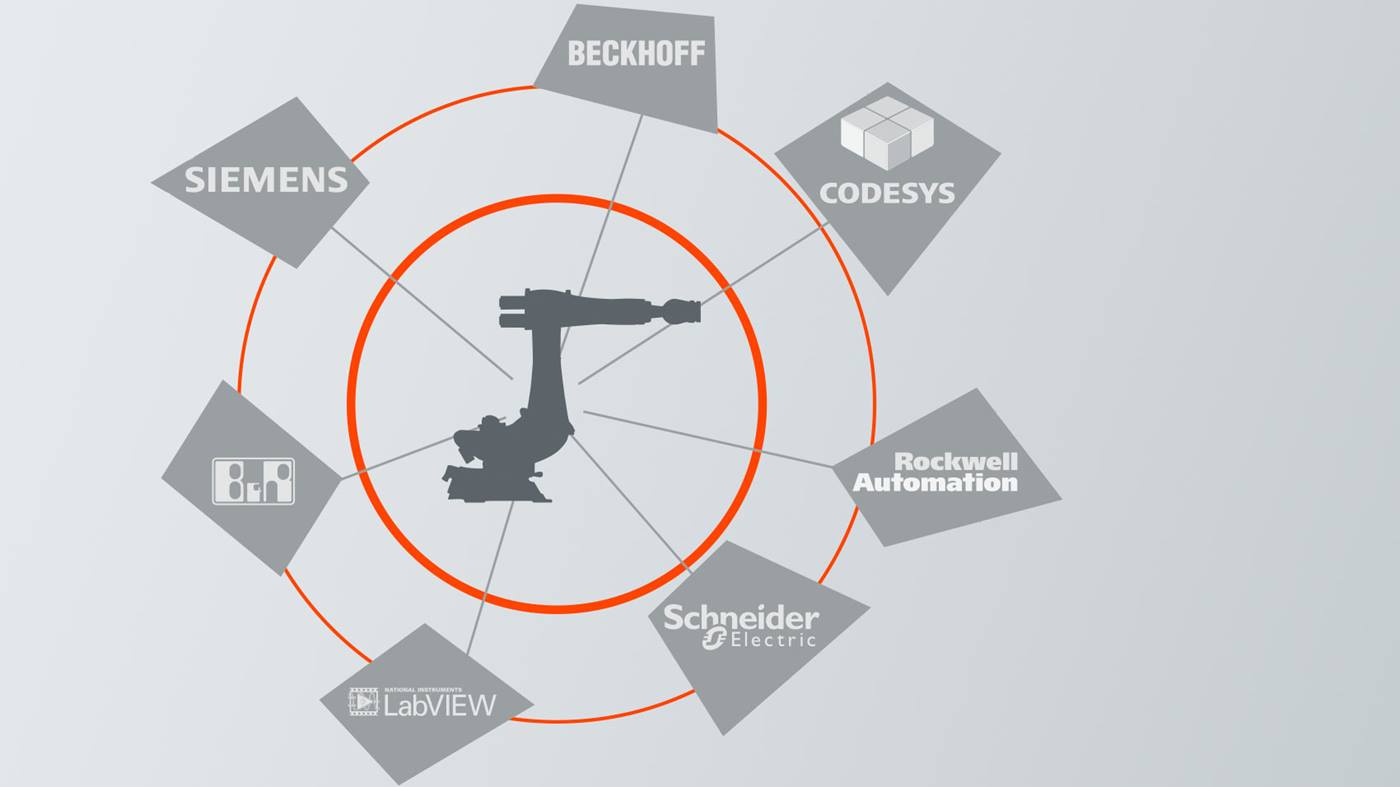

K is considered the world's most important trade fair for the plastics and rubber industry. This year, its focus is on the circular economy, digitalization and climate protection. Visitors will learn how KUKA helps companies increase productivity while reducing their carbon footprint. At booth B54 in Hall 12, you can experience which robots, software and complete automation solutions are already standing the test and which ones can advance the industry in the future.