KR SCARA robots: Designed for maximum efficiency in every aspect

The KR SCARA make automation in cost-sensitive industries easier and sustainably more economical. Equipped with intelligent features, the horizontal jointed-arm robots from KUKA offer an attractive overall package: light and slim, at the same time extremely fast and strong, and equipped with a high load capacity. It is a perfect solution for automation in tight spaces.

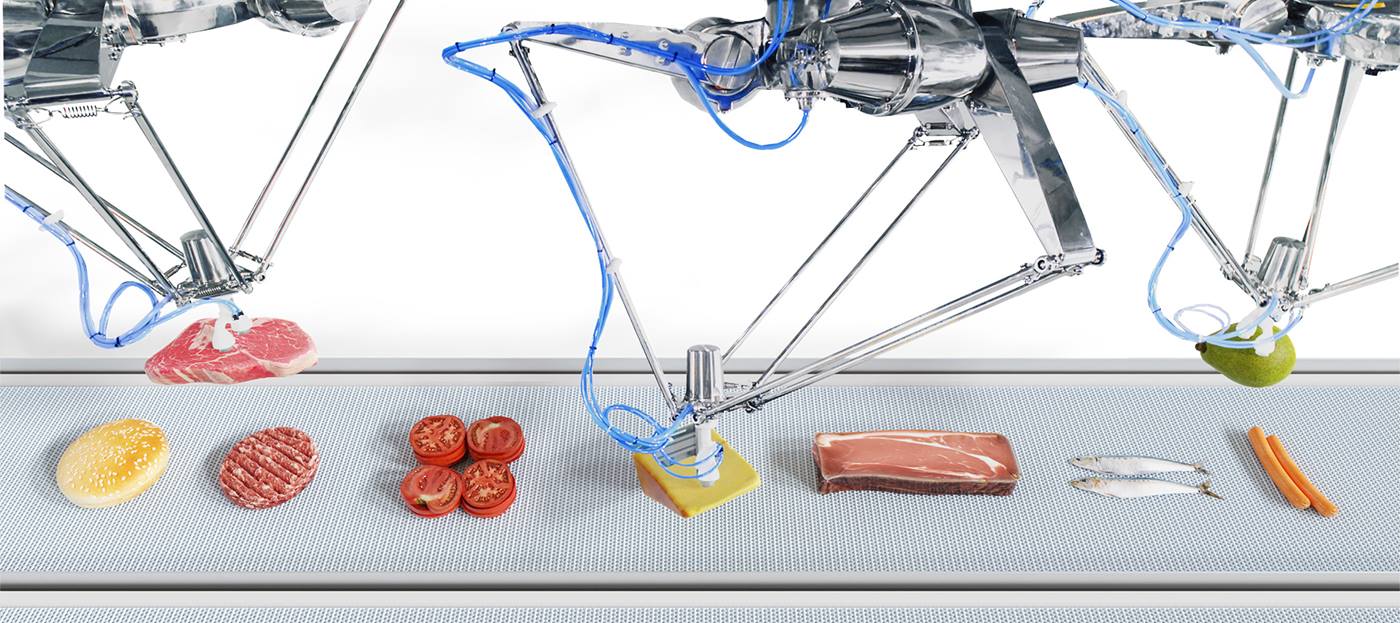

KUKA SCARA robots for assembly and joining tasks as well as for pick-and-place applications

The KR SCARA has an internal media supply system for air, power and data. This is a complete robotics package for smart integration of peripheral devices and rapid adaptation of the SCARA robot to almost any application. Whether small parts assembly, material handling or testing – the KR SCARA are flexible in installation, highly precise in their movements and easy to maintain. This makes such kinematics attractive, for example, for screwdriving applications in assembly, especially in electromobility, the electronics industry and in the field of renewable energies as well as in biomedicine and food industry – since speed, with consistent accuracy, is what counts here.