What is a cobot?

By definition, a cobot is a collaborative or collaborating robot that works in close proximity to human employees. The alternative designations of corobots, collaborative robotics or cobotics are also used.

You are using Internet Explorer and will not be able to use our website properly.

Please change to an up-to-date browser for ideal presentation of the website.

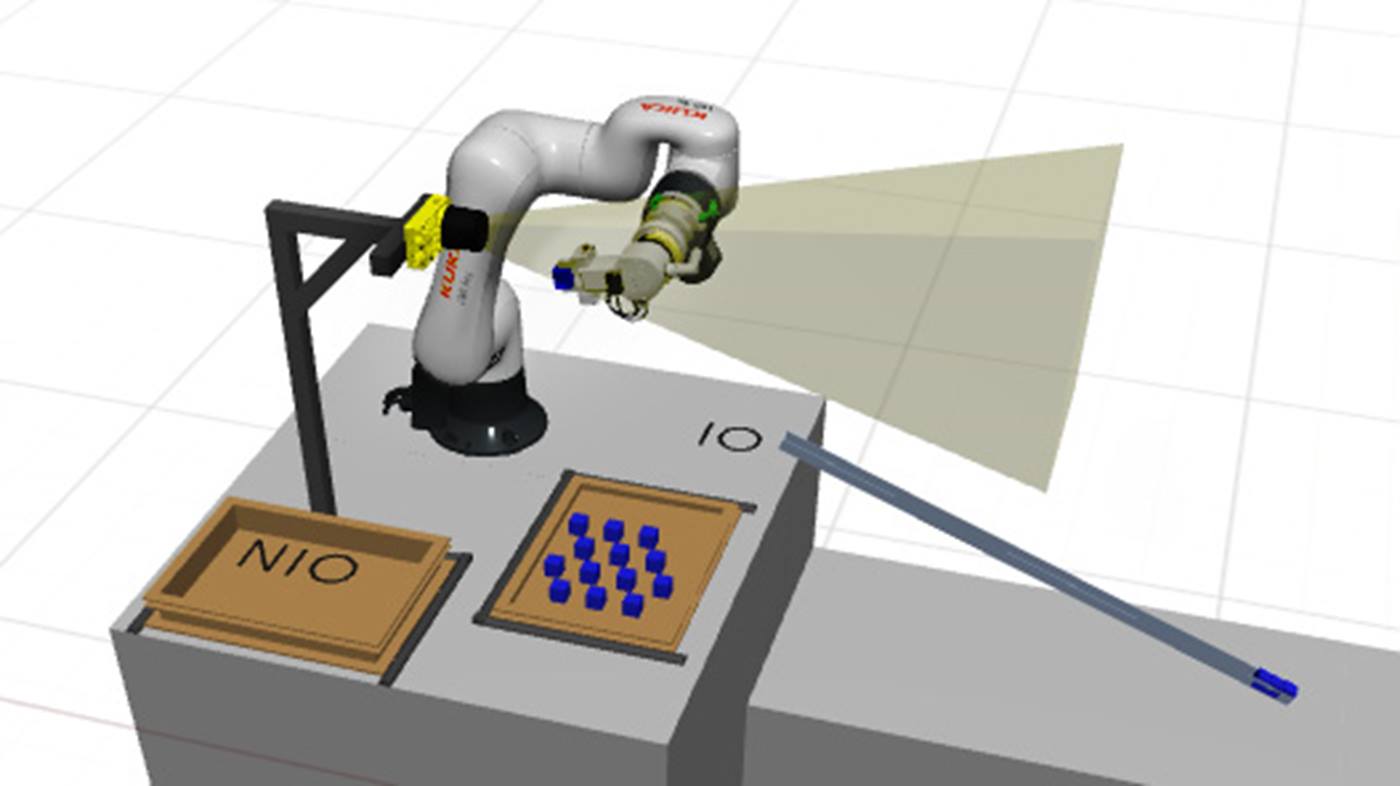

KUKA developed the world’s first collaborative robot back in 2014 and is setting new standards with current innovations. The very good price/performance ratio and the ease of commissioning KUKA cobots enable even small and medium-sized companies to enter the world of automation quickly and successfully.

By definition, a cobot is a collaborative or collaborating robot that works in close proximity to human employees. The alternative designations of corobots, collaborative robotics or cobotics are also used.

Unlike traditional industrial robots, the collaborative robot may work with human workers in a shared workspace without a safety fence. Sensors ensure that the robot never injures its co-workers. Conventional industrial robots, on the other hand, require a physical safeguard for the safety of human workers, which prevents them from working together.

Use cases highlight the effective collaboration of cobots side-by-side with humans in both industry and medicine

The iiQKA.OS operating system is designed for intuitive and fast start-up. Moreover, the KUKA TechCenter is available to help you with the successful integration of the new machine into your production system. Together with certified system integrators, our experts use feasibility studies and simulations to test and put together the right components for your applications. On top of this, we examine possible software additions. Users can also share suggestions and find support via the User Forum.

Opting for and investing in automation is generally less expensive now than it was in the early days. The procurement costs usually pay for themselves after a short time due to the efficient application possibilities making the cobot a very cost effective option for the automation of your production. Our robot systems are characterized by low maintenance costs, and they run smoothly and can be checked regularly by experts.

The preconfigured iiQKA robot systems come with hardware and software components: The compact KR C5 / KR C5 micro controller, powerful iiQKA.OS operating system, smartPAD pro teach pendant, end effectors and LBR iisy cobot are optimally coordinated with one other. Within a few minutes they are unpacked, set up and ready for use.

The graphical user interface of iiQKA.OS is designed to be self-explanatory and user-friendly enabling simple operation – with all functions and without compromises.

With the intuitive iiQKA.OS operating system and compatible components from the Robotic Republic, the KUKA ecosystem, users can easily create their own robot applications. In this way, even beginners can automate production steps by themselves.

The number of guaranteed compatible partner products, including vision systems, grippers, and various types of End-of-Arm Tooling, in the Robotic Republic is growing steadily, opening up ever more new applications for KUKA cobots.

Simply implement advanced programming such as inserting if/else commands: You will find all the necessary information and instructions on how to use and create commands in the help function of the user interface. In case of difficulties, detailed tutorials on my.KUKA and our experts in the User Forum will help you.

There are numerous areas of application for flexible cobots in industry. The sensitive robots enable human-robot collaboration (HRC) by reacting intelligently to their environment and being intuitively programmable. As a result, they can take on an ever-increasing range of more diverse tasks – either cooperating with humans in real-time or working on same workspace. Collaborative robots from KUKA offer great potential for manufacturing in high-mix, low-volume production environments, such as:

Stationary applications:

Mobile solutions for logistics and intralogistics: