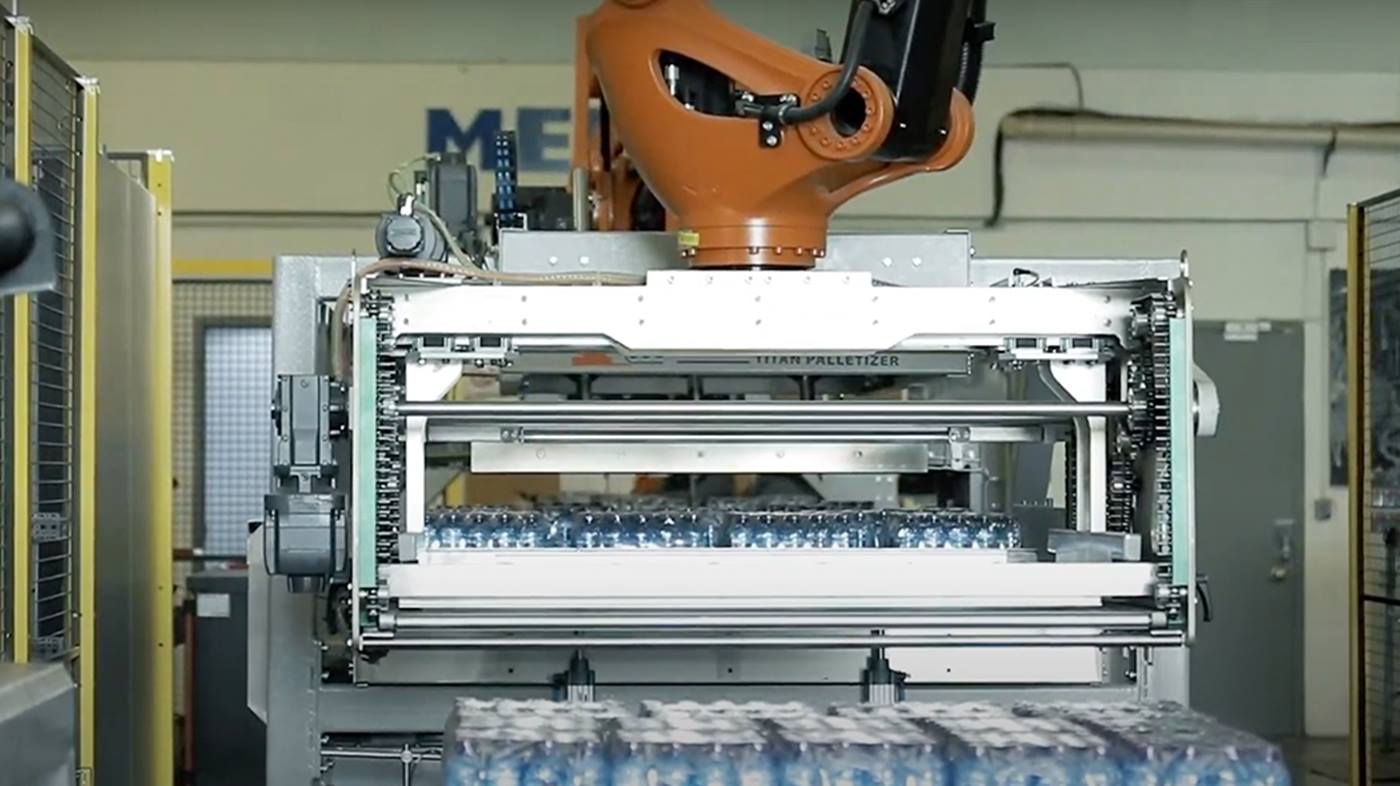

Quick stacking: KUKA robots palletize water bottles

Three different KUKA palletizers stack water bottles on pallets - quickly and precisely, layer by layer - at a water factory in Ramah, Saudi Arabia. Integrated KUKA software solutions make the process work.

“Automation was the logical approach for us”

Palletizers perform precise preparatory work on the conveyor

Easy changing of setdown formations

Playing for high stacks: KR 700 PA scores highly in terms of reach

One of the fastest lines in the beverage industry

Through the KUKA.PLC mxAutomation software, a simple system-controller setting modifies the formation of the water bottles in each pallet layer.

Increased system productivity and lower costs

The automated solution also makes it possible to process several different types of beverage bottles simultaneously for continuous production and greater flexibility at times of high demand. Short changeover times, achieved through a simple touch on the user interface, enable the Ramah Water Factory to achieve still more time savings, which yields a lower total cost of ownership and higher product quality. Gentle handling of bottles and packages during automatic sorting, bundling and stacking minimizes deformation or damage to the goods.

“Our customer is highly satisfied with the solution we developed using KUKA technologies,” confirmed Bashir Alqatanani. “In particular, the simple changeover of layer configurations thanks to KUKA.PLC mxAutomation has convinced the employees.” Integrator MEMCO intends to continue working on the palletizing line, however, to make it even faster – and MEMCO will continue to rely on KUKA solutions in the future.