Industrial robotics in mechanical engineering

Automated machining of workpieces: KUKA robots as machine tools

August 2, 2016

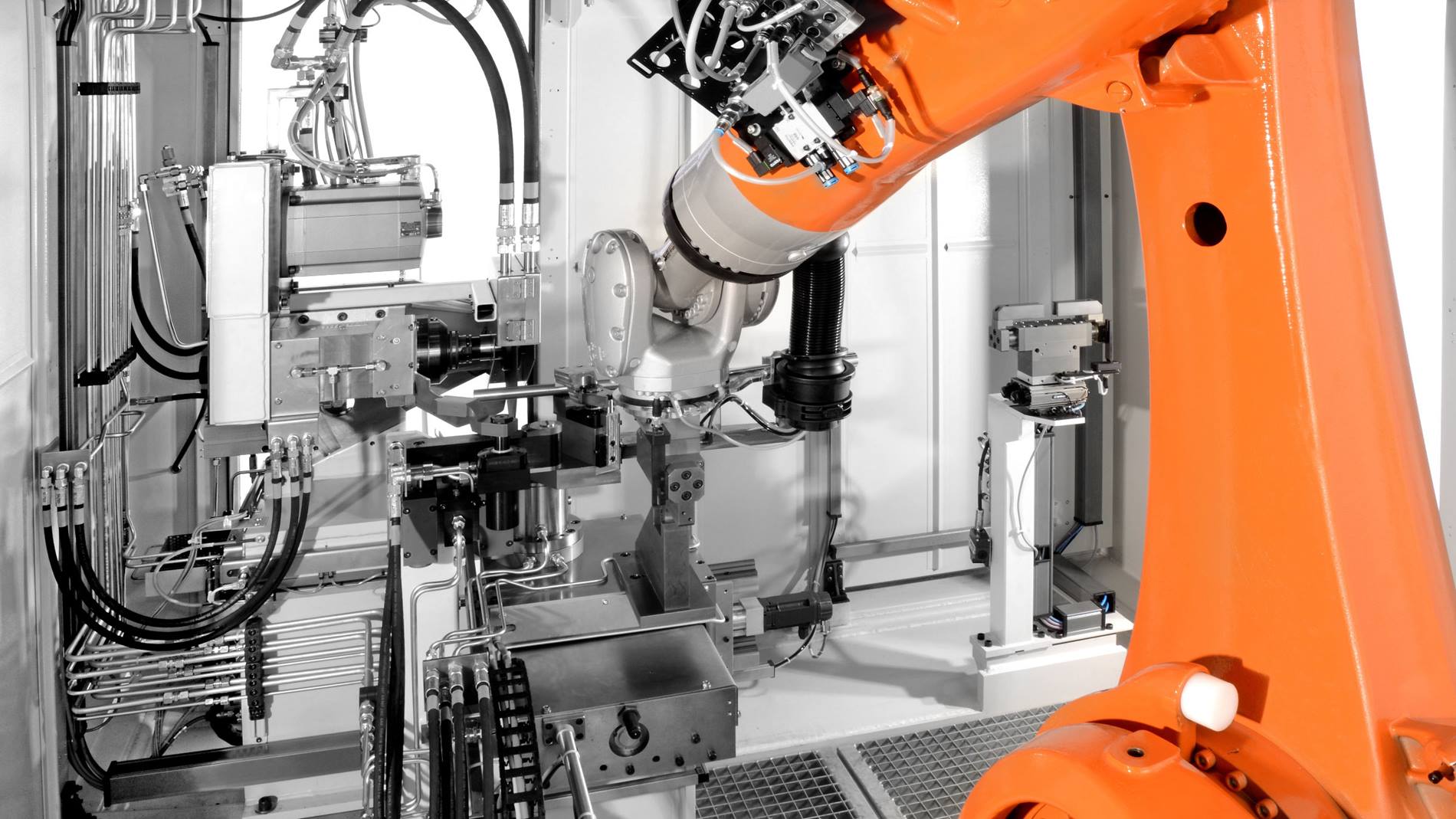

At Wieland Anlagentechnik GmbH, a KUKA robot from the KR QUANTEC series performs the handling and cutting of workpieces. The KUKA.mxAutomation interface to the Siemens CNC SINUMERIK 840D sl with Run MyRobot ensures simple operator control.

Industrial robot for high payloads cuts workpieces

Precision is the decisive factor in machining processes. At Wieland Anlagentechnik GmbH, a KUKA KR 180 R2500 extra F carries out all of the process steps for the machining of workpieces. Additionally, the robot removes the workpiece from the loading station and, depending on requirements, places it in a clamping fixture. The robot then performs the feed motion in the direction of the cutting tool.

The corrosion-resistant foundry variant of the kr quantec robot is dustproof and waterproof

The core of the system at Wieland Anlagentechnik GmbH is the KR 180 R2500 extra F. The industrial robot from the KR QUANTEC series is characterized by versatility, flexibility and precision. The Foundry variant of the robot is used since there is very high humidity within the system due to the coolant used. The special Foundry wrist with corrosion-resistant V2A materials is dustproof and waterproof – thus protecting the robot.

The KUKA.mxAutomation interface with the SINUMERIK Operate user interface enables simple operator control

Simple operation is important to Wieland Anlagentechnik GmbH with the aim of allowing as many operators as possible to control the robot and of minimizing downtimes. The robot is connected to the Siemens user interface SINUMERIK Operate via the KUKA-Siemens interface KUKA.mxAutomation or Run MyRobot. The widely used user interface allows for tasks such as operation, teaching and diagnostics to be easily controlled and carried out on the machine controller or the handheld HT8 terminal.

Broad field of application for robot machining cells in the future

“Our approach is to combine the flexibility and comparatively favorable working envelope of a robot with the high precision and stiffness of a machine tool. This makes it possible to machine large and geometrically challenging workpieces precisely and cost-effectively,” says Tobias Ziesel, who is in charge of Sales and Marketing at Wieland Anlagentechnik GmbH. Wieland Anlagentechnik is currently planning its next robot machining cells.

Find out everything about further KUKA Robots in the Foundry variant.

KUKA will be presenting solutions for metalworking companies at AMB, the international exhibition for metalworking, in Stuttgart from 13 to 17 September. Visit us in Hall 8 at Booth 8A69.