KUKA Showcases Complete Metal Joining Portfolio at FABTECH

KUKA Robotics will highlight its decades of experience and extensive portfolio of metal joining technology at FABTECH 2022 November 8-10.

October 28, 2022

Among those technologies in booth C11347, visitors will experience live demonstrations of robotic Friction Stir Welding (FSW), automated linear units and positioners, software that synchronizes the action of multiple robots working in the same application and an automated cell for surface bonding pretreatment using plasma.

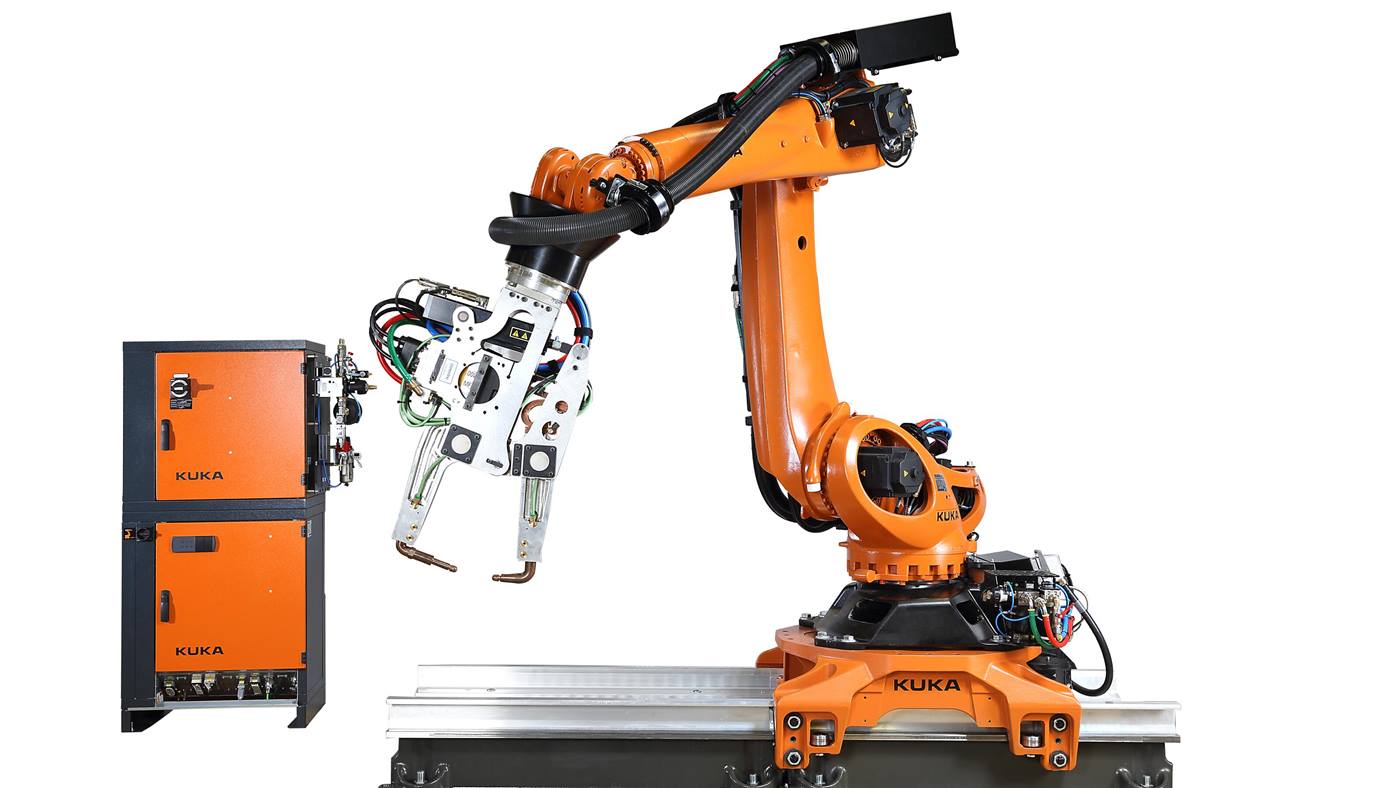

The multi-robot FSW cell will feature the high-payload KUKA KR QUANTEC robot that delivers best-in-class performance in applications ranging from automotive, foundry and welding aluminum parts to manufacture and assembly. Within the cell, one robot will pick parts from bins and place them into a fixture, and a second robot will perform the weld using both Roboception and SICK PLB 3D vision technologies.

For EV battery tray production, KUKA has engineered its cost-effective KUKA cell4_FSW modules to provide up to 95% more process efficiency and maximize the available configuration options for manufacturers. Used for both 2D and 3D welding tasks, the modules are scalable and accommodate either one or two 6-axis robots. Shops can arrange several workpiece clamping tools in the working area of the cell so that robots can work simultaneously on larger components if needed.

Visitors to the KUKA FABTECH booth will also see how the KL 4000 linear unit extends robot work envelopes with an exterior axis that provides translational motion of up to 31.5 meters in overall length. KUKA linear units use the same controller as that of the robot and add an additional axis to seamlessly integrate into the work sequence without the need for additional equipment. Linear units accommodate up to four robots and are available in various sizes and payload categories.

KUKA will also spotlight its broad line of robotic positioners that enhance performance and automation for increased efficiency and output. Three KUKA positioners, the KP1-HC, KP3-VCH and DKP, will be highlighted during the show, demonstrating their wide variety of applications and payloads. For accuracy and production quality, KUKA positioners employ proven robotic components for high availability and reliability as well as maximum torque for extremely short cycle times.

For the geometric coupling of multiple robots, the KUKA.RoboTeam Coordinated Motion software synchronizes motion start and motion time of two or more robots for state-of-the-art production. KUKA.RoboTeam transfers decision making and responsibility of conventional, centralized PLC functions directly to the robot group for autonomous group execution.

To meet ongoing demand for increased efficiency and standardization for surface bonding pretreatment solutions, KUKA Robotics will spotlight its ready2_activate application with System Partner Plasmatreat.

Utilizing a KR AGILUS robot and KUKA’s ready2_activate application and modular platform, Plasmatreat Openair-Plasma jet technology will perform high-precision surface cleaning by activating or nanocoating material surfaces, preparing surfaces for gluing, printing or lacquering without generating any chemical waste. The KUKA robotic motion sequence and plasma process are controlled by processors in close communication for easy integration into a production line or process.

Utilizing a KR AGILUS robot and KUKA’s ready2_activate application and modular platform, Plasmatreat Openair-Plasma jet technology will perform high-precision surface cleaning by activating or nanocoating material surfaces, preparing surfaces for gluing, printing or lacquering without generating any chemical waste. The KUKA robotic motion sequence and plasma process are controlled by processors in close communication for easy integration into a production line or process.