Recycling robot tackles electrical waste

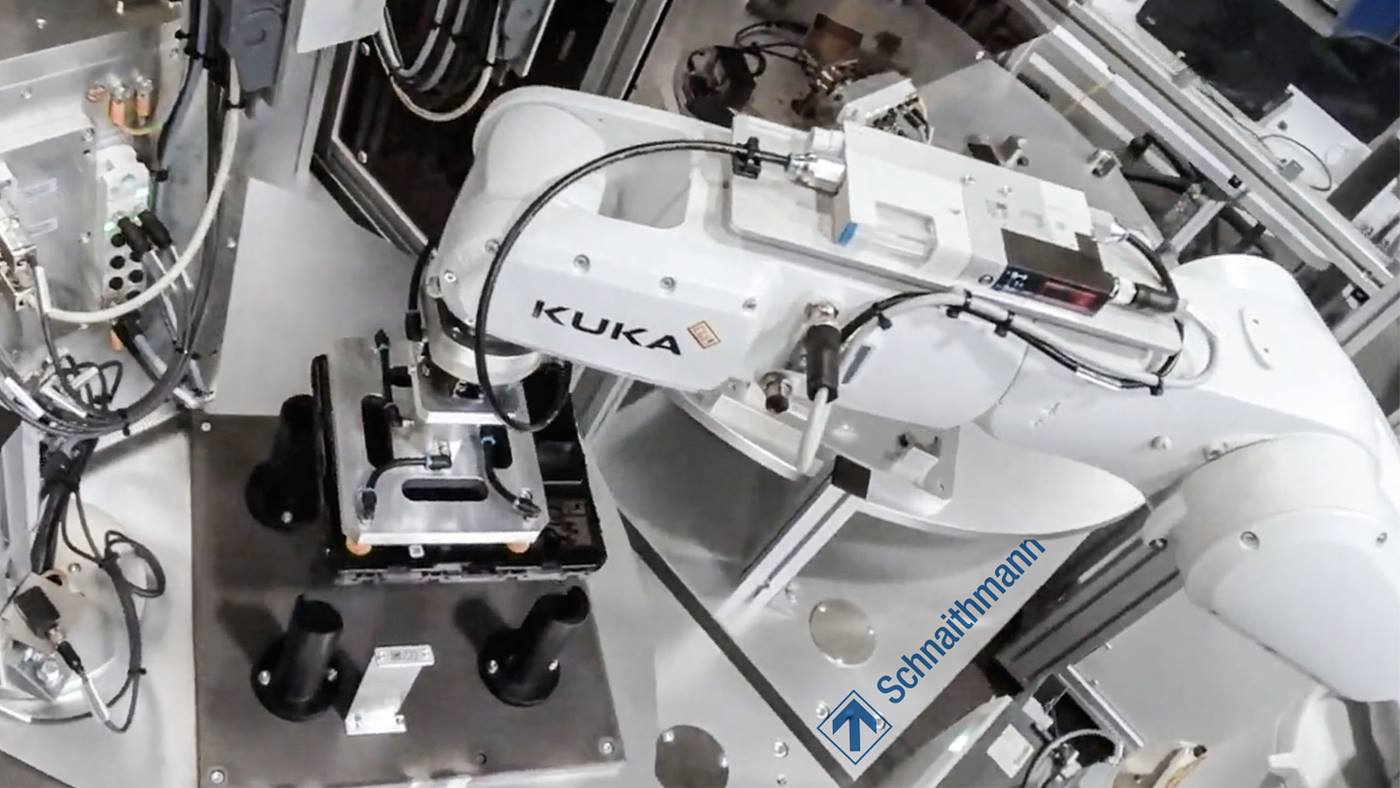

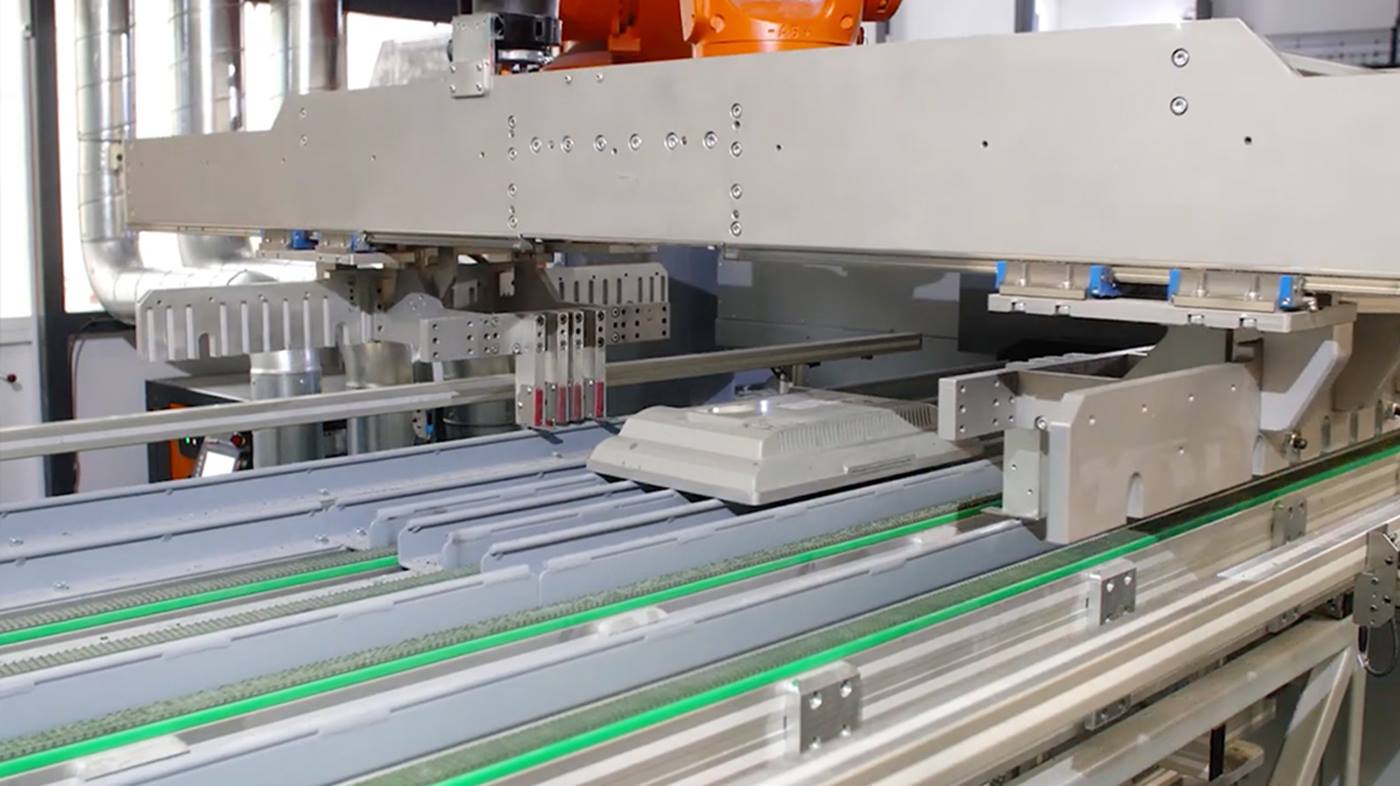

A sustainable circular economy depends on recycled electronic consumer goods, but recycling electronic waste can endanger human workers – which makes it an optimal application for robotics and automation. To overcome these challenges, the Irish technology company Votechnik has developed a system based around a KUKA KR QUANTEC industrial robot.

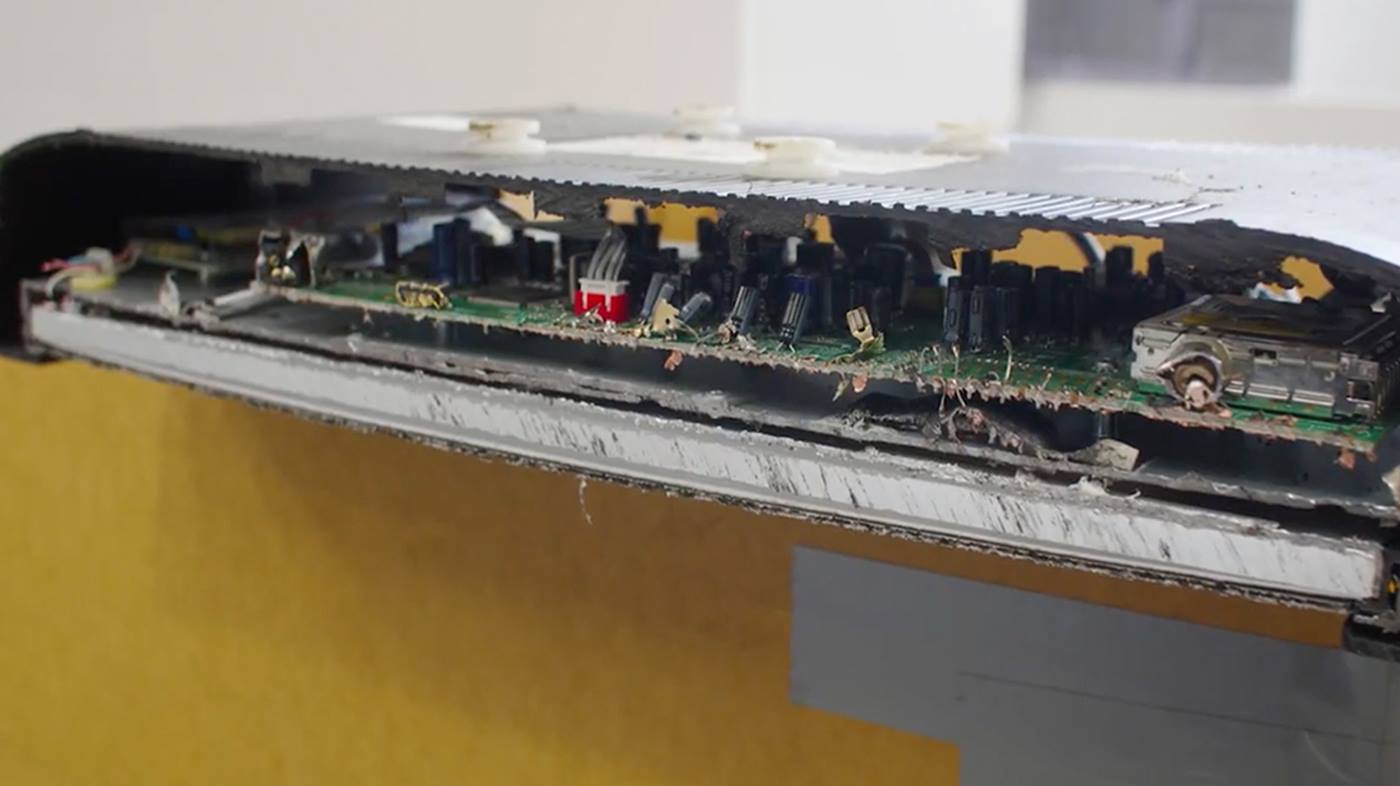

The possible consequences of 200 million LCD televisions

Recycling: robots reduce hazards for humans

KR QUANTEC: the heart of the recycling system

An automated process with recycling robots eliminates the need for human contact with hazardous gases and liquid crystals, as well as the risk of injury – for example, from the broken glass produced during extraction of fluorescent tubes and television screens from LCD devices. Because of high payloads, the ALR-4000 system uses the KUKA KR QUANTEC industrial robot. “The KR QUANTEC is our most ecologically friendly robot, a perfect fit for the waste recycling environment,” said Brian Cooney.

The KR QUANTEC offers outstanding operating efficiency and cost-effective commissioning and maintenance. Its modular design greatly reduces the number of components, which, in turn, helps minimize maintenance requirements. Innovative cabling and power supply concepts also reduce operating costs. The robot itself also is up to 90% recyclable.

Extracting what's valuable, enclosing what's dangerous

Carbon block filters enable plug-and-play system

The robust and reliable KR QUANTEC as a partner

Global servicing and support