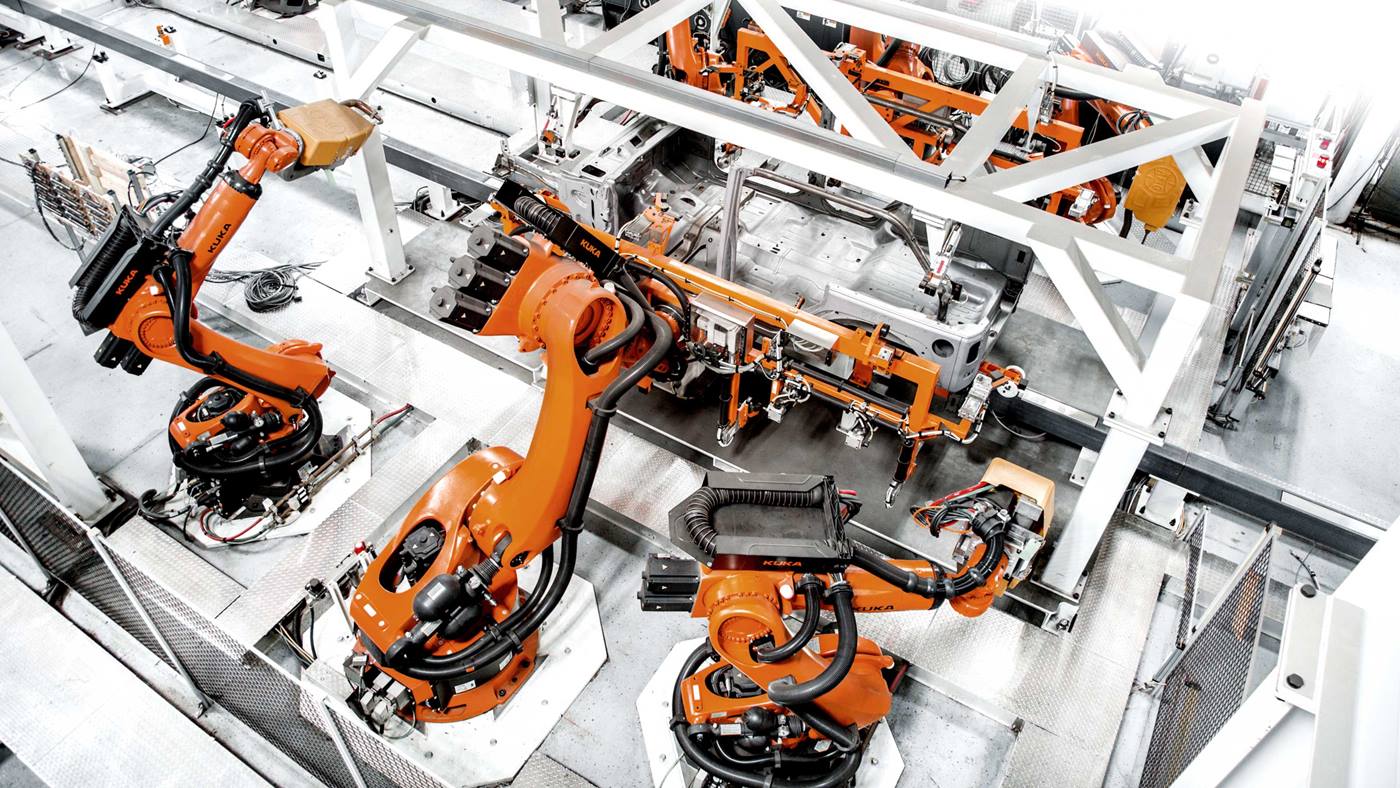

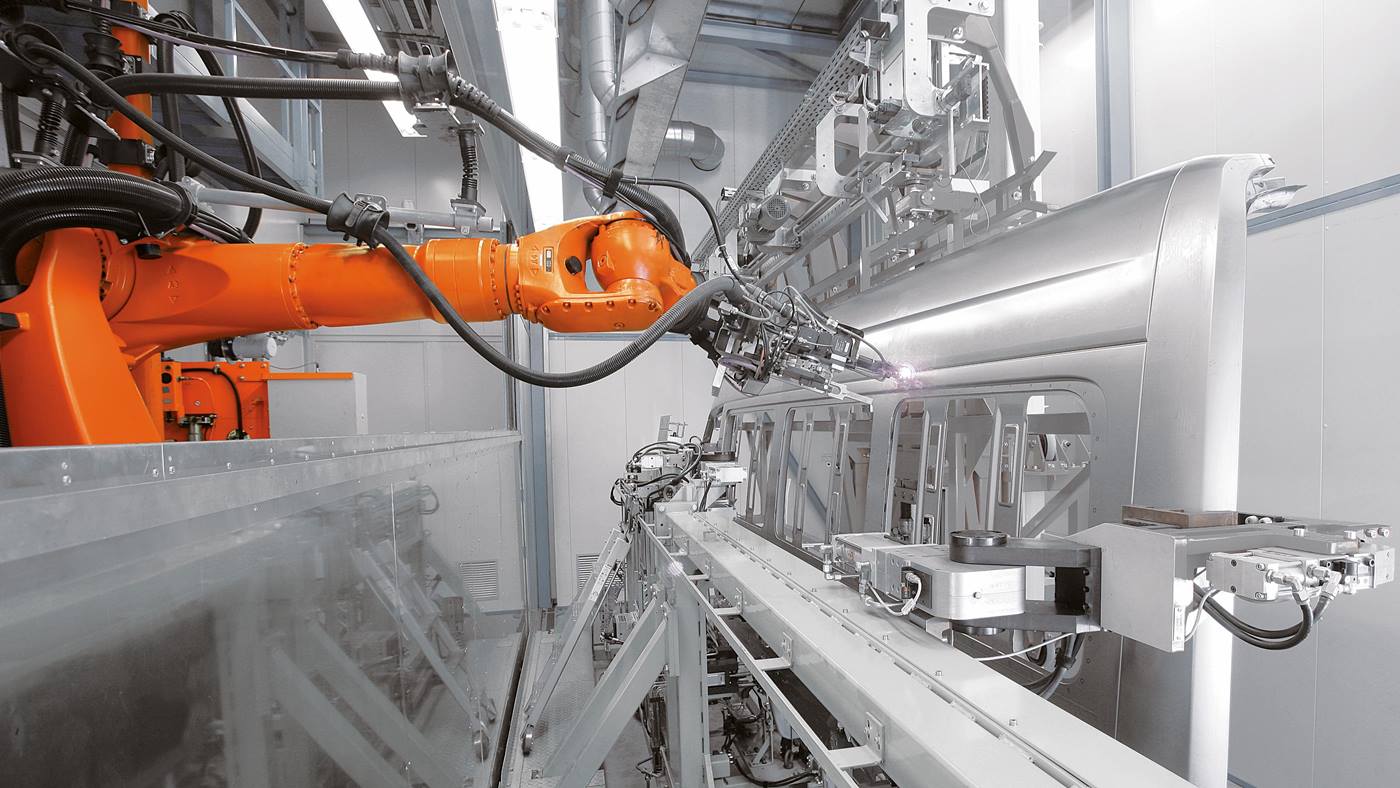

Flexible automation: Standardized or customized – both are possible

Efficiency and speed are often crucial in industry. That is why the KUKA Group offers standardized automation solutions that can be implemented quickly and have proven themselves in many applications. They are ideal when short delivery times and ready-to-use systems are required.

But not every challenge can be overcome with an off-the-shelf solution. For complex or particularly specific requirements, we work with our partners to develop customized systems – precisely tailored to the individual processes and goals of our customers.

Our solutions are used across a wide range of industries, including automotive, electronics, consumer goods, food, e-commerce, medicine, and many more.